CLR2160 — Clear Ice Maker

08/2006

13

www.U-LineService.com

CAUTION

Plumbing installation must observe all state and local

codes. All water and drain connections MUST BE made by

a licensed/qualified plumbing contractor. Failure to follow

recommendations and instructions may result in damage

and/or harm.

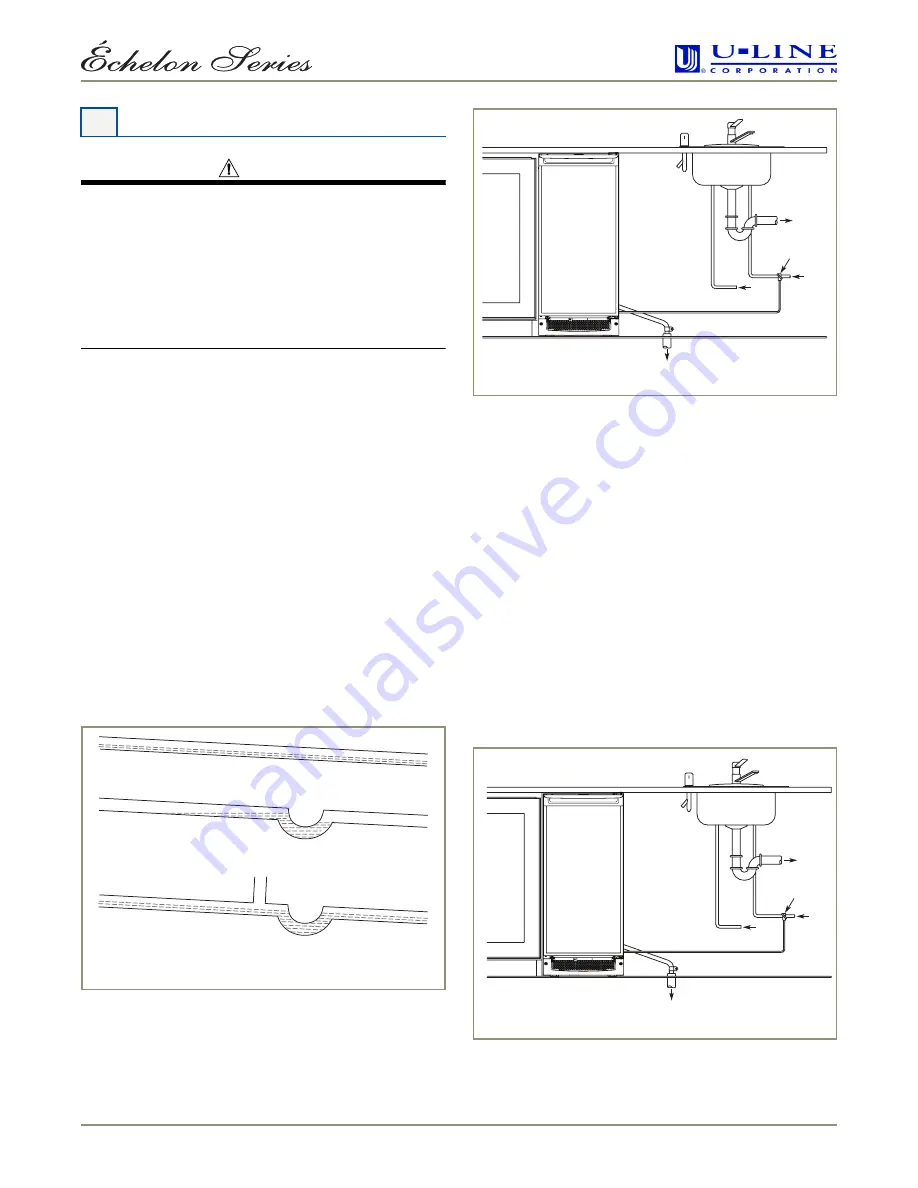

Drain Connection

IMPORTANT

Drain can NOT be located directly below unit. Unit has a

solid base that will not allow unit to drain below itself.

The CLR2160 can be installed using a Gravity Drain, a

Factory-Installed Drain Pump (U-Line P60) or a Locally-

Installed (U-Line P60) Drain Pump. Drain lines must have a

5/8-inch inside diameter. The floor drain must be large

enough to accommodate drainage from all attached

drains.

Follow these guidelines when installing drain lines to

prevent water from flowing back into the ice maker

storage bin and/or potentially flowing onto the floor,

causing water damage:

Gravity Drain

A Gravity Drain may be used if:

• Drain line has at least a 1-inch drop per 48 inches of

run (1/4 inch per foot).

• Drain line does not create traps or created traps are

vented (see

Figure 31

).

See

Figure 32

for a typical Gravity Drain installation.

If using a Gravity Drain:

1. Attach the 5/8-inch ID drain connection on the back of

the unit to a 5/8-inch OD rigid tube, using a worm

clamp.

2. Attach the other end of the rigid tube to your 5/8-inch

ID drain line with a worm clamp.

3. Insulate the drain line, if necessary to prevent

condensation. Go on to

Water Supply Connection

.

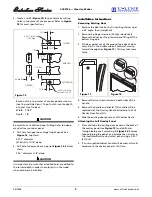

Factory-Installed Drain Pump

If your drain line will run up to a stand pipe, disposal

assembly or spigot assembly or does not otherwise meet

the requirements for a Gravity Drain, you may have

ordered the CLR2160 with a U-Line P60 Drain Pump. See

Figures

33

,

34

and

35

for typical installations requiring a

Drain Pump. If you need to install a P60 Drain Pump into

your unit, see

Locally-Installed Drain Pump

on

Page

15

.

6 Prepare Plumbing

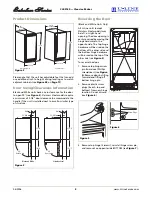

Normal

Proper Drain

With Trap

Poor Drainage, Water Will Back Up

With Trap and Vent

Proper Drain

Figure 31

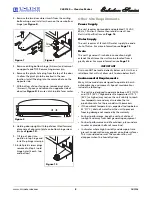

Waste

Waste

Cold

Water

Shut-Off

Valve

Hot

Water

Figure 32

Gravity Drain

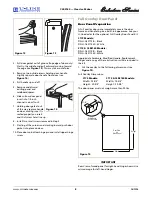

Waste

Waste

Cold

Water

Shut-Off

Valve

Hot

Water

Figure 33

Stand Pipe