CLR2160 — Clear Ice Maker

08/2006

15

www.U-LineService.com

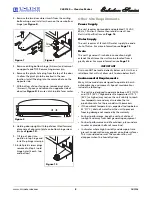

5. Place a suitable container beneath the pump’s discharge

tube. (The bucket must be able to hold a minimum of

one gallon.)

6. Plug the ice maker power cord into a properly

grounded, polarized electrical outlet.

7. Verify pump operation by pouring one gallon of water

into the ice storage bin of the ice maker. The pump

should energize and pump the water into the container.

8. At this time, verify that all tube and clamp connections

are tight and leak free.

9. Unplug unit power cord from electrical outlet.

10. Reinstall back panel.

To connect to drain:

1. Attach the 5/8-inch ID drain connection on the back of

the unit to a 5/8-inch OD rigid tube, using a worm

clamp.

2. Attach the other end of the rigid tube to your 5/8-inch

ID drain line with a worm clamp.

3. Insulate the drain line, if necessary to prevent

condensation. Go on to

Water Supply Connection

.

Locally-Installed Drain Pump

If a gravity drain connection is not possible, and you have

not purchased the CLR2160 with factory-installed pump,

we strongly recommend the use of the U-Line P60 drain

pump. The U-Line P60 drain pump is available through

your Dealer, or direct from U-Line with complete

installation instructions. If a pump other than the U-Line

P60 drain pump is to be used, it must meet the following

specifications:

• It must be UL listed and have a UL listed, 120 VAC,

3-wire grounded power cord.

• It must have overall maximum outside dimensions of

8-3/4" wide x 5-3/4" deep x 7-3/4" high.

• It must have a minimum flow rate of 1.5 gallons per

minute at 10 feet of lift.

• It must have a sealed sump which does not allow water

leakage in the case of a power outage, restricted drain

or pump failure.

• It must have a check valve in the discharge line to

prevent waste water return to the pump.

• It must have an overflow protection control which will

shut off power to the ice maker in the event of a pump

failure.

• It must have an operating temperature range of 50°F

to 110°F (10°C to 40°C).

CAUTION

In the event of a power outage, restricted drain or pump

failure, the failure to use the U-Line P60 drain pump or a

pump with the above listed specifications, could result in

substantial water leakage and pooling with severe and

costly water damage and related consequential damages

and harm.

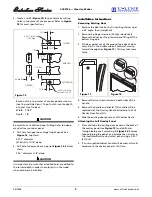

Water Supply Connection

When connecting the water supply, follow these

guidelines:

• Review the local plumbing codes before you install the

unit.

• Connect to the cold water supply.

• The water pressure should be between 20 and 120 psi.

• Install a shut-off valve in the 1/4 inch OD water supply

line.

• Connect sufficient tubing to the unit so that tubing

may be looped, allowing the unit to be removed for

cleaning and servicing (see

Figure 41

). However, make

certain that the tubing is not pinched or damaged

during installation.

Note:

U-Line recommends the use of copper tubing

for installation.

The use of other types of tubing is not

recommended due to potential aftertaste & deterioration

over time.

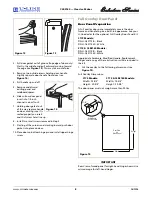

To connect to water supply:

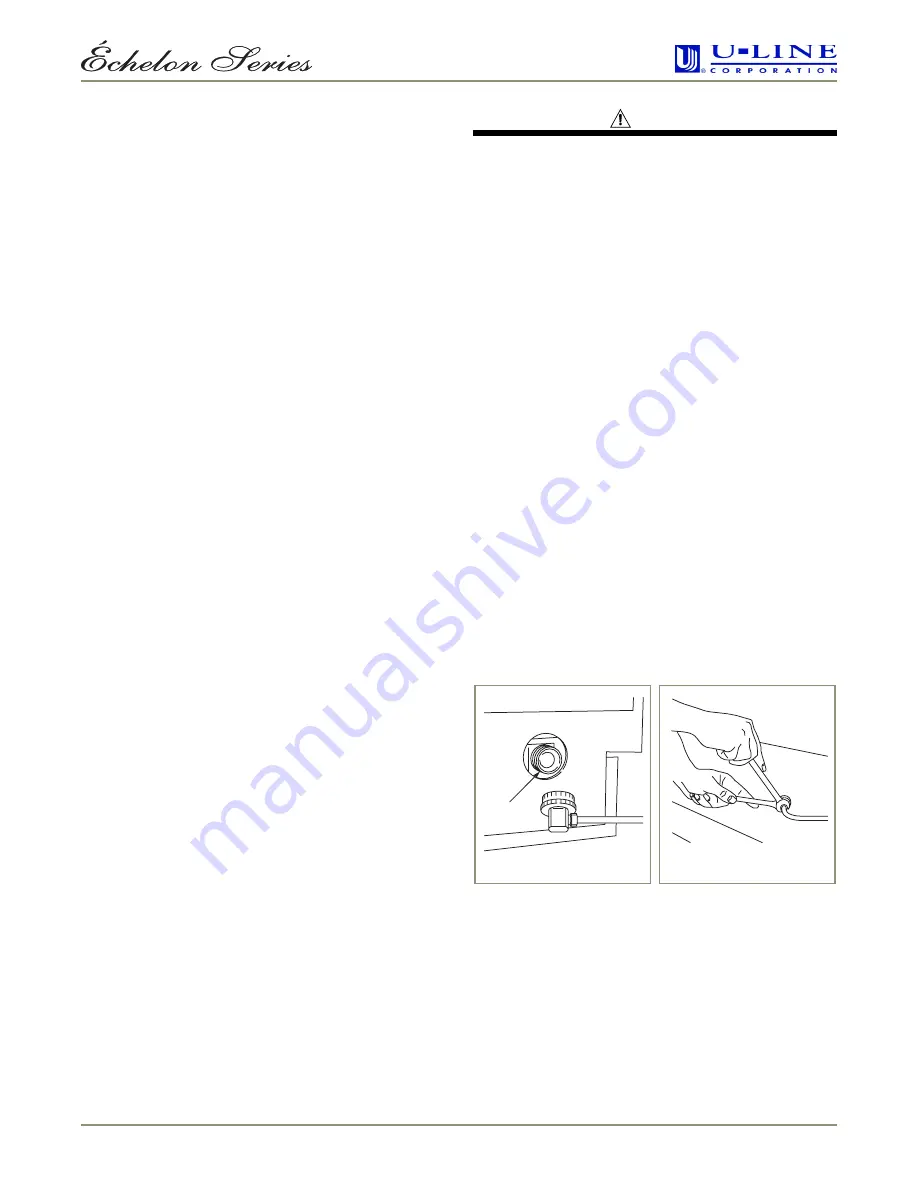

1. Install the 1/4 inch OD copper water line from the

main water source (see

Figure 38

).

2. Locate the compression fitting and ferrule packed with

the unit. Slide the compression fitting and ferrule over

the 1/4-inch OD water supply line. Do not use thread

sealing compound or tape. Using two wrenches, tighten

the compression fitting on the supply line (see

Figure

39

).

Figure 39

Figure 38

Water

Connection