CLR2160 — Clear Ice Maker

08/2006

17

www.U-LineService.com

Leveling Information

IMPORTANT

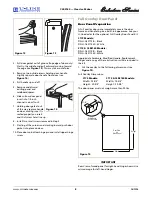

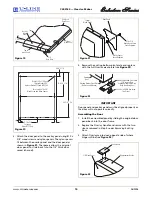

It is extremely important that the unit is level. If it is not

level, the ice mold will not fill evenly.

A unit that is not level can

cause a reduction in ice rate,

uneven sized cubes or water

spilling into the storage area,

which will cause the ice in

the bin to melt prematurely

(see

Figure 43

).

Remember that floors near

drains have a tendency to

slope towards the drain.

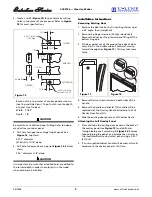

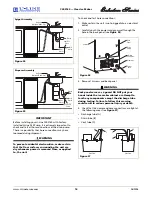

1. Use a level to check the

levelness of the ice maker

from front to back and

from side to side. Level

should be placed along

top edge and side edge

as shown (see

Figure 44

).

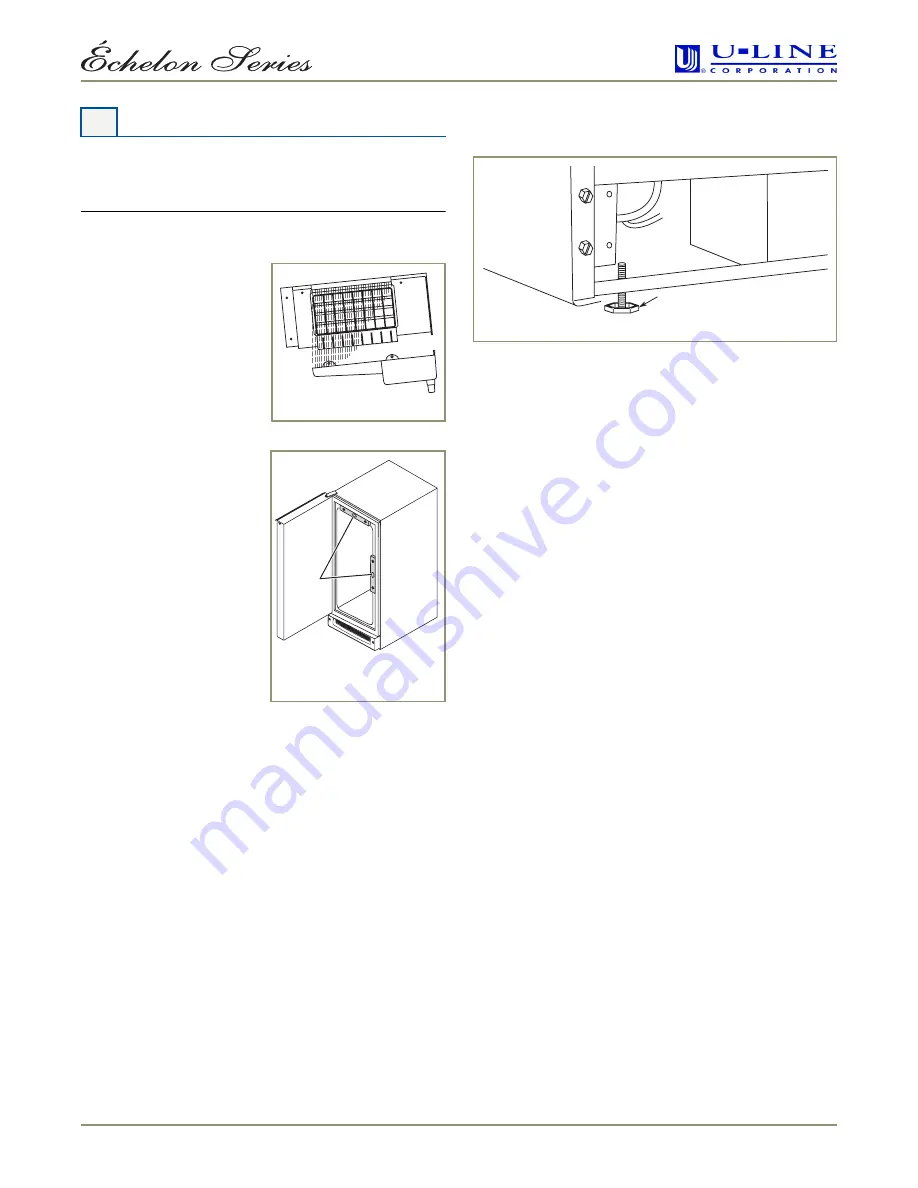

2. If the ice maker is not level, adjust the feet on the

corners of the unit as necessary (see

Figure 45

).

3. Check the levelness after each adjustment and repeat

the previous steps until the unit is level. Go on to

9 Install the Unit

.

Installation Tip

If the room floor is higher than the floor in the cut-out

opening, adjust the rear feet to achieve a total unit rear

height of 1/8" less than the opening’s rear height. Shorten

the unit height in the front by adjusting the front feet.

This allows the unit to be gently tipped into the opening.

Readjust the front feet to level the unit after it is correctly

positioned in the opening.

8 Level the Unit

Figure 43

1

ULIN_0043_A

Figure 44

Turn Foot to Adjust

Figure 45