CLR2160 — Clear Ice Maker

www.U-LineService.com

4

08/2006

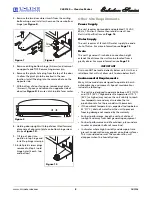

After all the protective coating has been removed from

the unit/door, clean all Stainless Steel surfaces with Claire

Stainless Steel Polish and Cleaner or comparable product

or a mild detergent and warm water solution and soft

cloth. Do NOT use abrasive cleaning agents.

Note:

If cleaning with mild detergent and warm water

solution and soft cloth, the unit MUST be treated with

Claire Stainless Steel Polish and Cleaner or comparable

product to prevent discoloration.

Exterior Cleaning

(As Required)

Black and White Models:

• The door, grille and cabinet may be cleaned with a mild

detergent and warm water solution. Do not use

solvent-based or abrasive cleaners. Use a soft sponge

and rinse with clean water. Wipe with a soft, clean

towel to prevent water spotting.

Stainless Steel Models:

• Stainless steel models can discolor when exposed to

chlorine gas, pool chemicals, salt water or cleaners with

bleach.

• Keep your stainless steel unit looking new by cleaning

with a good quality all-in-one stainless steel cleaner/

polish on a monthly basis. For best results use Claire

Stainless Steel Polish and Cleaner, which can be

purchased from U-Line Corporation. (The part number

is 173348.) Comparable products are acceptable.

Frequent cleaning will remove surface contamination

that could lead to rust. Some installations may require

cleaning on a weekly basis.

• Do not clean with steel wool pads.

• Do not use cleaners that are not specifically

intended for stainless steel (this includes glass,

tile and counter cleaners).

• If any surface discolors or rusting appears, clean it

quickly with Bon-Ami or Barkeepers Friend Cleanser

and a non-abrasive cloth. Always clean in the direction

of the grain. Always finish this process with Claire

Stainless Steel Polish and Cleaner or comparable

product to prevent further problems.

• Use of abrasive pads such as Scotchbrite will

cause the graining in the stainless to become

blurred.

• Rust that is allowed to linger can penetrate into the

surface of the stainless steel and complete removal of

the rust may not be possible.

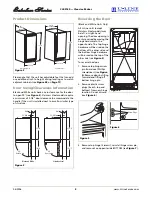

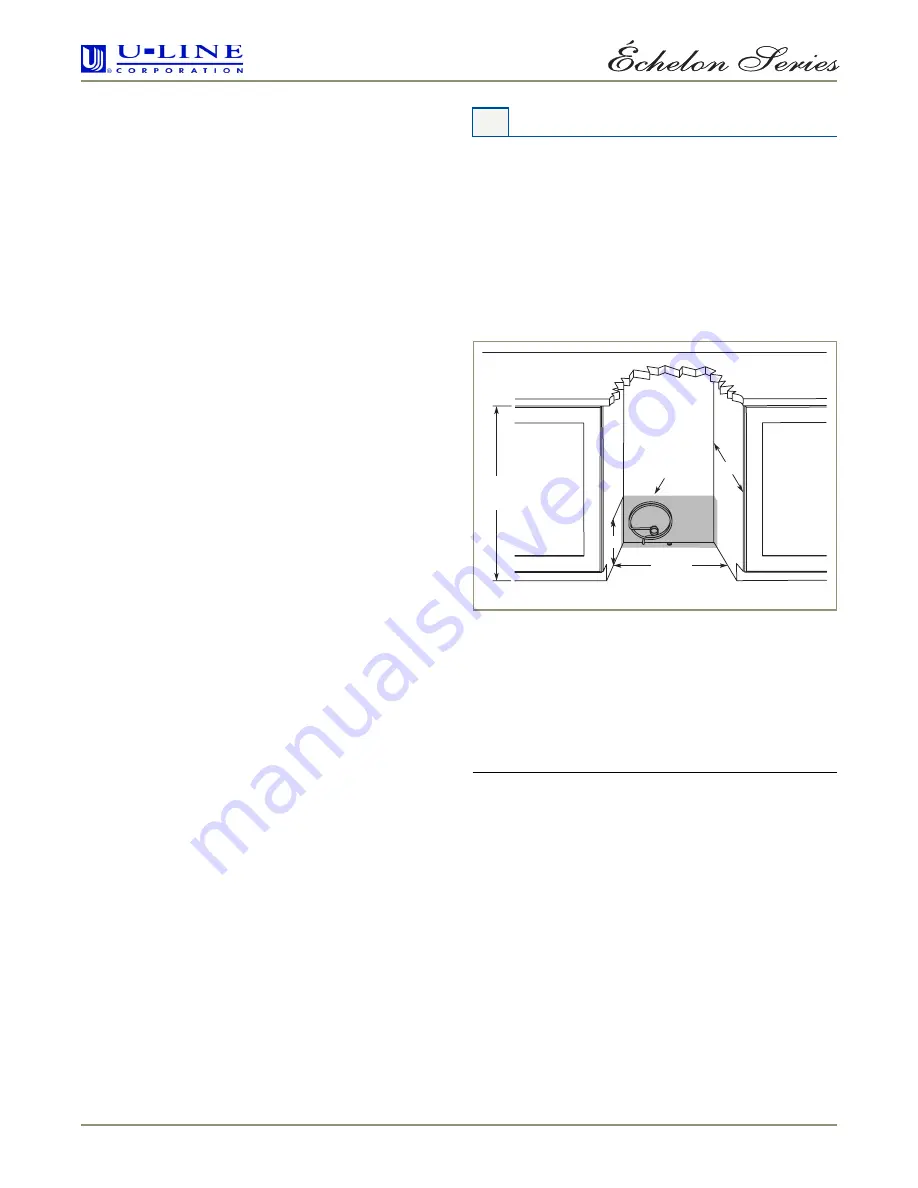

Your U-Line product has been designed for either free-

standing or built-in installation. When built-in, your unit

does not require additional air space for top, sides or rear.

However, the front grille must NOT be obstructed and

clearance is required for water, drain and electrical

connections in the rear.

Note:

Unit can NOT be installed behind a closed cabinet

door.

Cut-Out Dimensions

Follow the cut-out drawing in

Figure 1

. The 15-3/16"

width allows 1/4" for ease in installation and removal of

the unit. The 24" depth is the cabinet depth in most

installations. The unit is 24" deep including the handle

on Black and White models and 24" deep including the

door and

not

the handle on Stainless Steel models (see

Figure 2

).

IMPORTANT

If you would like to align the face of the unit with other

adjacent cabinet doors in certain installations, you may

need to alter the wall just behind the drain connection on

the unit to accommodate the drain. The actual amount of

alteration will be determined by your actual drain

connection components.

3 Prepare Site

See Electrical

Specifications

for Power Supply

34-1/4"

to

35-1/8"

15-3/16"

8"

24"

Figure 1