CLR2160 — Clear Ice Maker

www.U-LineService.com

6

08/2006

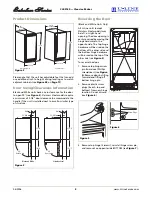

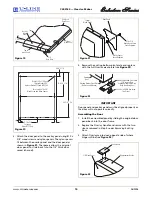

4. Remove the two door closer inserts from the existing

bottom hinge and install as shown on the new bottom

hinge (see

Figure 8

).

5. Remove existing bottom hinge (3 screws) and remount

on opposite side TOP. Remove hinge screw pin.

6. Remove the plastic hole plug from the top of the door

to allow the pivot pin to be inserted in the new

location. Install the plug into the vacated hole on the

opposite side.

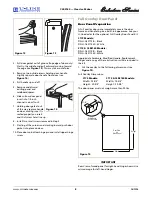

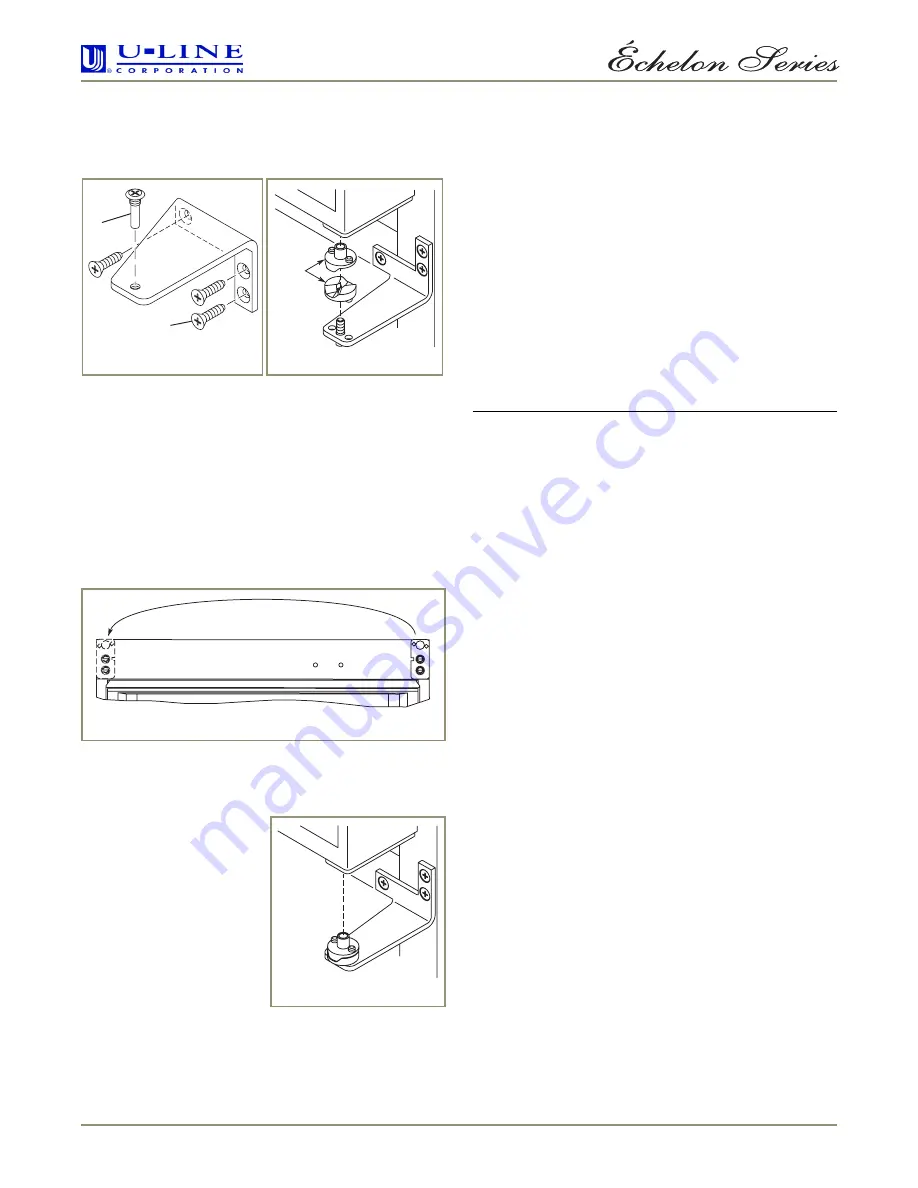

7. With bottom of door facing up, remove pivot plate

(2 screws), flip over, and remount on opposite side of

door (see

Figure 9

). Be sure notch in plate faces center.

8. Holding door upright with top of door tilted forward,

place hole of door pivot plate on bottom hinge screw

pin (see

Figure 10

).

9. Tilt top of door into

position in top hinge and

install top hinge screw pin.

10. Install plastic screw plugs

removed in Step 2 in old

hinge holes (3 each, top

and bottom).

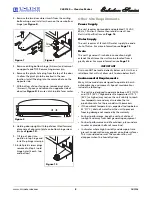

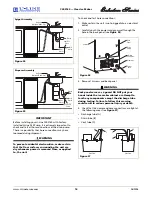

Other Site Requirements

Power Supply

The unit requires a grounded and polarized 115 VAC,

60 Hz, 15A circuit (normal household current). See

Electrical Specifications

on

Page 16

.

Water Supply

The unit requires a 1/4-inch OD water supply line and a

shut-off valve. For more information see

Page 15

.

Drain

The unit’s generous 7-inch drain connection height

extends the distance the unit can be located from a

gravity drain. For more information see

Page 13

.

IMPORTANT

Drain can NOT be located directly below unit. Unit has a

solid base that will not allow unit to drain below itself.

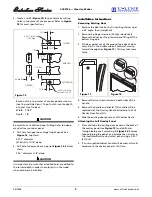

Environmental Requirements

Many U-Line models are designed to operate in harsh

outdoor/marine environments. Special considerations

include the following:

• The units are designed to operate between 50°F (10°C)

and 110°F (40°C). High ambient temperatures (110°F

[40°C] or higher) may reduce the unit’s ability to reach

low temperatures and may also reduce the ice

production rate for those models with icemakers.

• If the ambient temperature is expected to drop below

45°F (7°C), drain all water from the unit to prevent

freezing damage not covered by the warranty.

• For best performance, keep the unit out of direct

sunlight and away from heat generating equipment.

• For best performance and life outdoors, place under a

counter or provide shelter of some kind.

• In climates where high humidity and dew points are

present, condensation may appear on outside surfaces.

This is considered normal. The condensation will

disappear when the humidity drops.

Figure 7

Figure 8

Door

Closer

Inserts

1

2

ULIN_0003_A

Figure 9

Figure 10