CLR2160 — Clear Ice Maker

08/2006

7

www.U-LineService.com

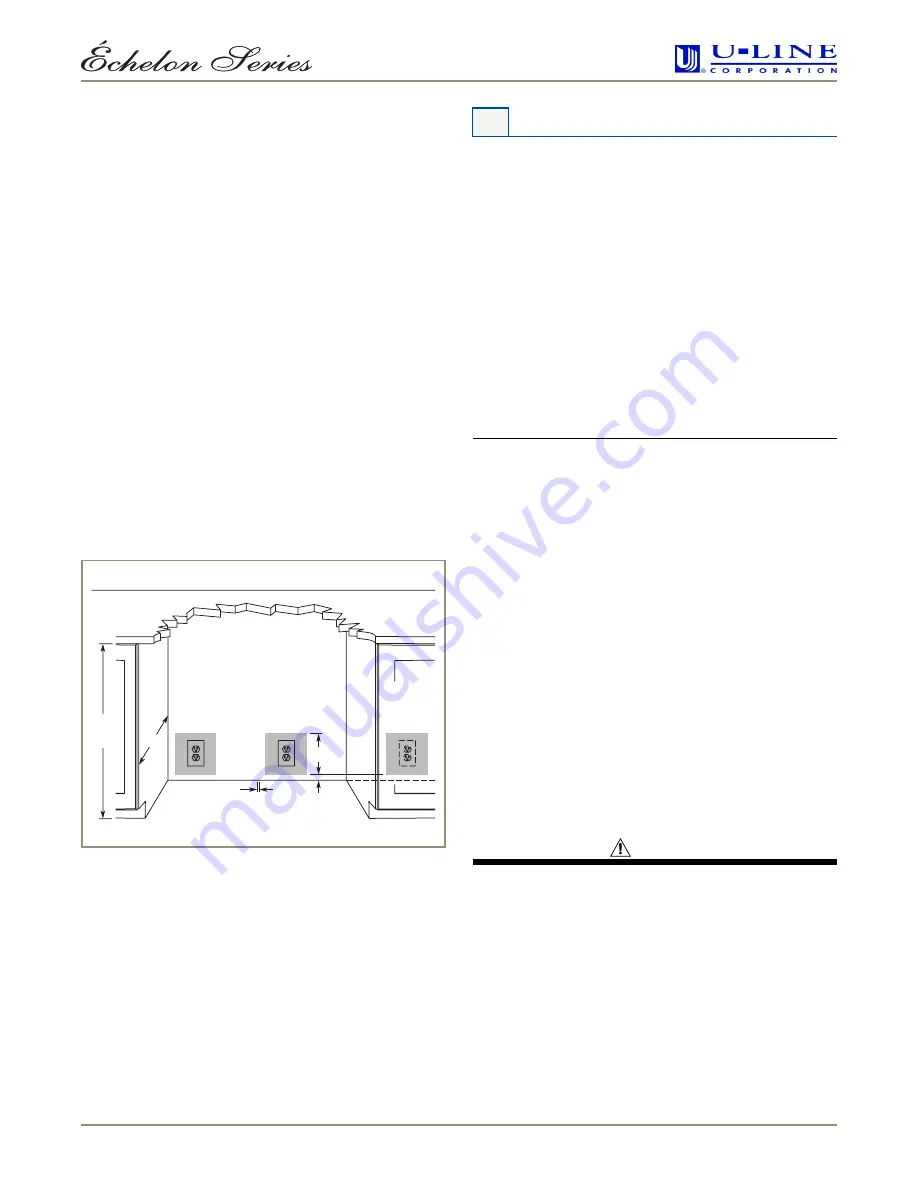

Side-By-Side Installation

Instructions

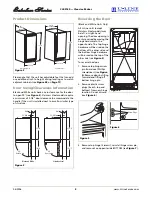

For a complete refreshment center, install your CLR2160

Clear Ice Maker beside a U-Line Refrigerator, Combo, or

Wine Captain Model (see

Figure 11

for typical cut-out).

Note that each Side-By-Side Installation will be different.

• Cut-out width for a side-by-side installation is the total

of the widths listed under

Cut-Out Dimensions

in each

unit’s Installation Guide.

For example:

Placing a CLR2160 Clear Ice Maker next to a 2115 series

unit would require a cut-out width of:

15-3/16" + 15-3/16" = 30-3/8"

Placing a CLR2160 Clear Ice Maker next to a 2175 series

unit would require a cut-out width of:

15-3/16" + 24-3/16" = 39-3/8"

• No trim kit is required. However, 1/4-inch space needs to

be maintained between the units to ensure

unobstructed door swing.

• Units must operate from separate, properly grounded

electrical receptacles placed according to each unit’s

Electrical Specifications

.

(Black and White Units Only)

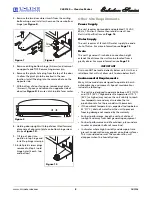

Two types of custom door panels can be installed on your

Black or White unit to harmonize with or accent the

surrounding décor: a Custom 1/4" Insert or a Full Overlay.

If no custom door panel is used, go on to

5 Adjust Door

.

Custom 1/4'' Door Panel Insert

Door Panel Preparation

A custom door panel can be inserted into the door frame.

Custom door panels can be flat or raised, as long as the

maximum panel thickness where inserted into the door

reveal (channel) is 1/4"-thick. For raised panels, the depth

of the reveal is 1/4" on all four sides.

IMPORTANT

Raised panels will reduce the door’s 90° swing/zero

clearance if the unit is installed next to a wall or similar

type of structure.

For

2175 models

cut the panel insert to the following

dimensions.

Custom 1/4" Dimensions:

Width:

23-1/32"

Height:

27-11/16"

For

2115 & CLR2160 models

cut the panel insert to the

following dimensions.

Custom 1/4" Dimensions:

Width:

14-1/32"

Height:

27-11/16"

The door panel must not weigh more than 20 lbs.

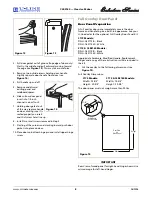

Door Panel Installation

Install the insert as follows:

CAUTION

Use care when handling the insert. Insert edges may be

sharp.

1. Remove top hinge screw pin (using a Phillips

screwdriver, see

Figure 12

). Remove door by tilting

forward and lifting off bottom hinge pin.

Acceptable

Location

Preferred

Location

for CLR2160

Receptacle

1"

7"

24"

34-1/4"

to

35-1/8"

1/4" Space

Between Appliances

Figure 11

Typical Side-By-Side Cut-Out

4 Prepare and Install Door Panel