CLR2160 — Clear Ice Maker

08/2006

9

www.U-LineService.com

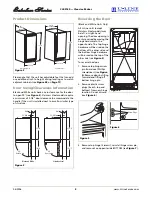

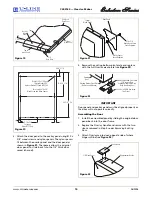

2. Create a relief (

Figure 15

) for pivot plate by cutting

notch in top corner of overlay panel. Refer to

Figure

16

for exact specifications.

Route notch in top corner of overlay panel as shown

(see Top and Side Views). Top of notch is entire depth

of panel, front to back.

Width: 31/32"

Depth: 1/8"

CAUTION

Be careful not to drill too deep! Drilling holes too deep

may destroy your door panel.

3. Drill hole for upper door hinge (top of panel) (see

Figure 16

, Top View).

0.177" diameter

(#16 drill) x 11/16" deep

4. Drill hole for lower door hinge (see

Figure 16

, Bottom

View).

5/16" diameter x 1/4" deep

CAUTION

It is important to ensure that all drilled holes are drilled to

the correct depth in order to avoid splits in the wood

when hardware is installed.

Installation Instructions

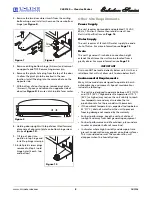

Removing Existing Door

1. Remove the door shelves by first pulling shelves up at

a 45° angle, then straight out.

2. Remove top hinge screw pin (Phillips screwdriver).

Remove the door by tilting forward and lifting off the

bottom hinge pin.

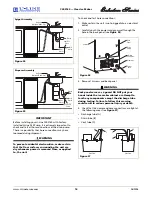

3. Pull door gasket out of the groove (top edge of door

only). Start in the middle and pull outward, moving

toward the edge (see

Figure 17

). This may take some

force.

4. Remove the two screws located on both sides of the

handle.

5. Remove the handle and discard. (This handle will be

replaced with the Overlay Handle included in the Full

Overlay Door Panel Kit.)

6. Slide the existing door panel out of the door frame.

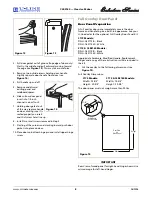

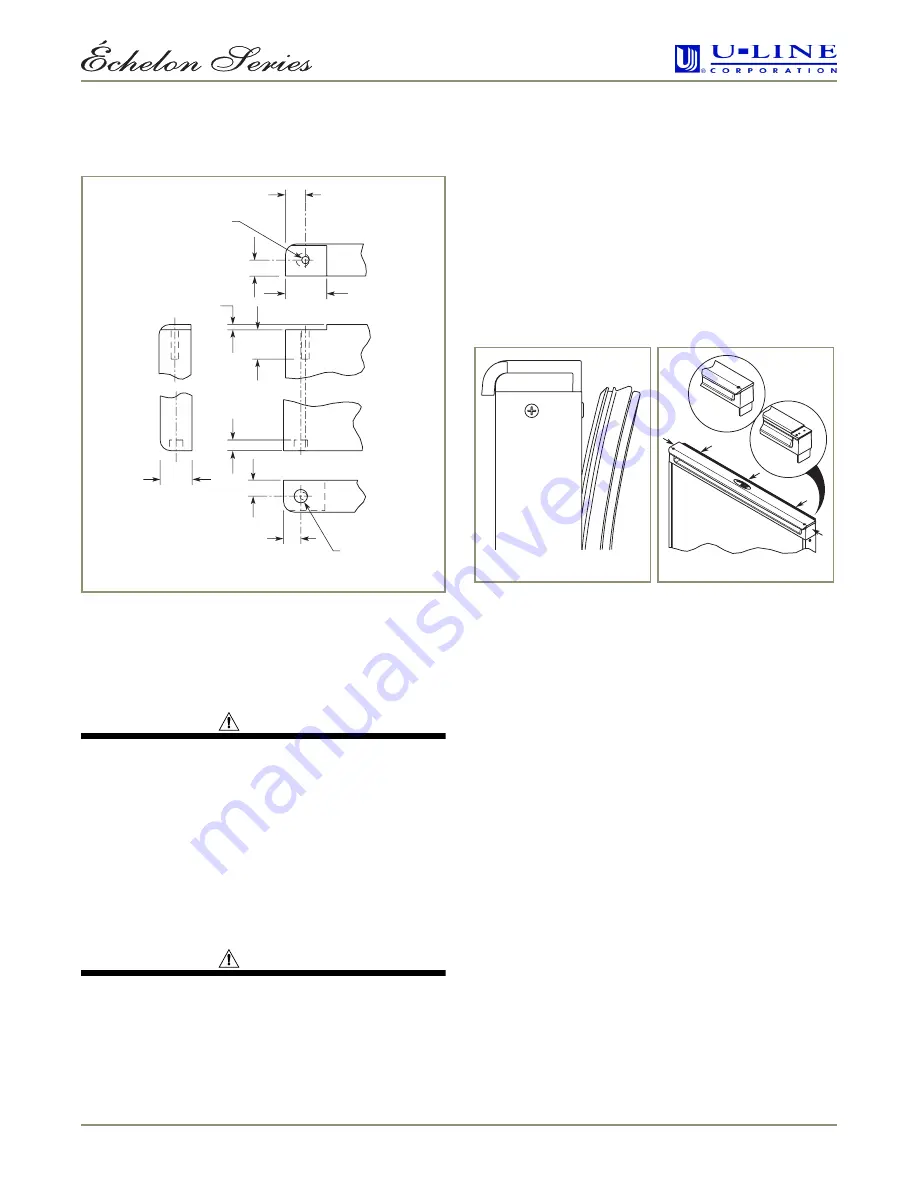

Attaching the Full Overlay Panel

1. Place and tape the existing door panel on the back of

the overlay panel (see

Figure 19

) and drill holes

through both panels according to

Figure 20

. Remove

tape adjoining the panels and enlarge the six holes in

the steel (black/white vinyl color) panel using a 0.201"

(#7) drill.

2. If a user-supplied cabinet handle will be used, attach its

hardware to the overlay panel at this time.

15/32"

3/8"

.125"

13/32"

31/32"

BOTTOM VIEW

BACK VIEW

SIDE VIEW

TOP VIEW

ø 0.177" (#16 Drill)

11/16" Deep

3/4" Min Ref

1/4" Ref

3/8"

11/16"

Ref

ø 5/16" x 1/4" Deep

Chamfer 1/32" x 45

°

ULIN_0401_A

Figure 16

New Handle

Old Handle

ULIN_0403_A

Figure 17

Figure 18