PAGE 9 OF 33

0913 IH-1619

SCALE CALIBRATION/OPERATION

1. Turn power off. Remove ‘X1’ plate from bottom of

display to expose calibration switch. (See Figure 2)

2. Slide calibration switch towards off/on switch to enter

calibration mode. (See Figure 3)

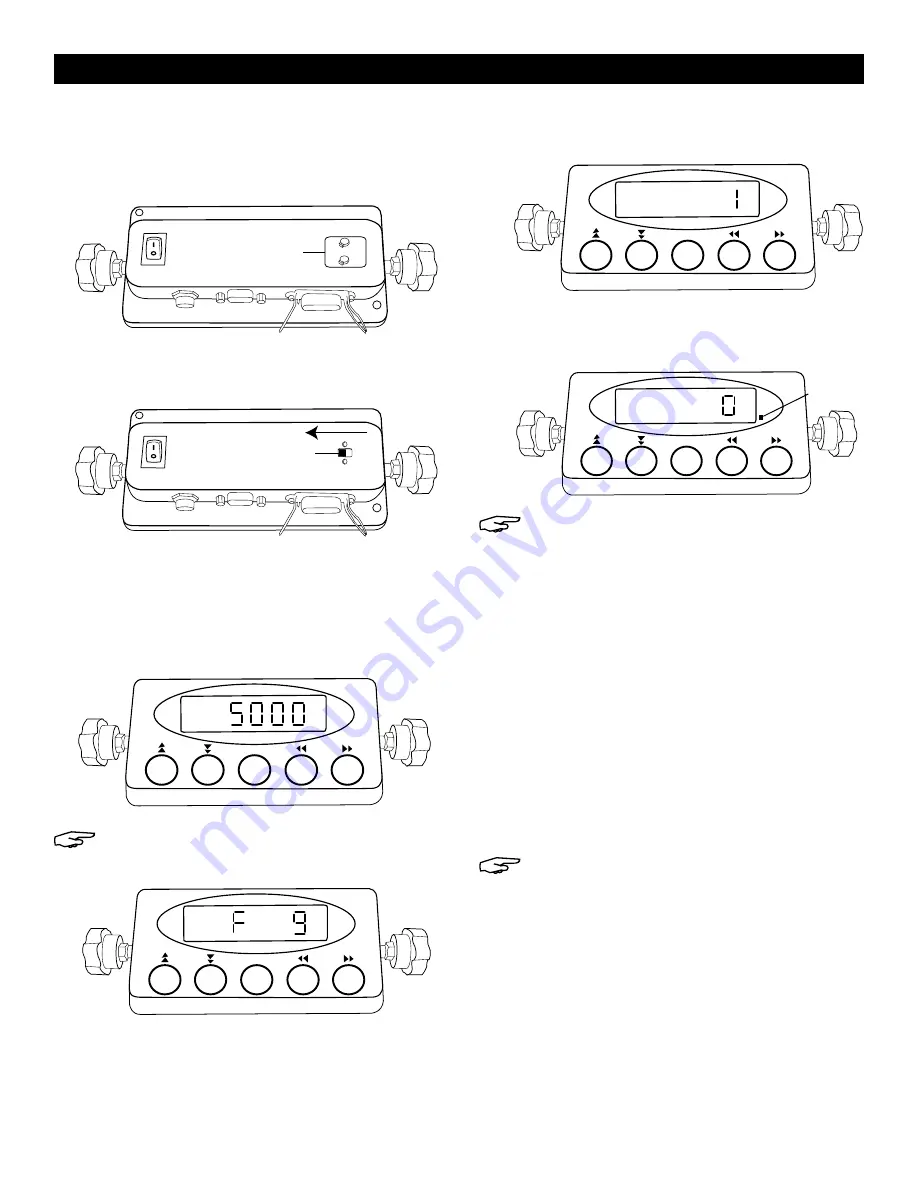

3. Turn power on. Display should read ‘F1’.

4. TO SET 5,000 LB. SCALE:

• Press ZERO and verify that screen shows ‘5,000’.

Press SET. Press UNITS. (See Figure 4)

NOTE: If screen does not show ‘5,000,’ press

UNITS or ZERO buttons.

• Press PRINT or TARE and scroll to F9. Press ZERO.

(See Figure 5)

• Set value to ‘1’. Press NET/GROSS to save.

Press UNITS to exit. (See Figure 6)

• Press PRINT to scroll to ‘F10’. Press ZERO and verify that

value is ‘0’. Press NET/GROSS to save. Press UNITS to exit.

(See Figure 7)

NOTE: If screen does not show ‘5,000’ press

UNITS or ZERO buttons.

5. TO STABILIZE SCALE:

• Remove any items from scale.

• Use PRINT or TARE to scroll to ‘F16’.

• Press ZERO.

• When stabilized, green light will appear.

(See Figure 7)

• Press ZERO. Press NET/GROSS. Screen will return to ‘F16’.

6. TO CALIBRATE SPAN:

• Using PRINT or TARE, scroll to ‘F17’. Press ZERO to enter

Span Calibration Menu.

• Use PRINT, TARE and ZERO to enter test weight (must be

at least 10% of scale capacity).

NOTE: pRINT and TARE move digit left or right.

UNITS and ZERO changes flashing digit.

• Place test weight on scale and allow unit to stabilize for

at least 30 seconds. Press NET/GROSS to return to ‘F17’.

• Do not remove weight. Slide calibration switch on

back to original position. Meter will count down and

read test weight on screen.

• Reinstall ‘X1’ plate.

• Scale is now calibrated and ready for use.

Calibration Switch

Figure 3

GROSS

NET

SET

TARE

ZERO

UNITS

Figure 4

GROSS

NET

SET

TARE

ZERO

UNITS

Figure 5

GROSS

NET

SET

TARE

ZERO

UNITS

Figure 6

GROSS

NET

SET

TARE

ZERO

UNITS

Green Light

Figure 7

Placa X1

Figure 2

CALIBRACIÓN/fUNCIONAMIENTO DE LA BÁSCULA

SCALE CALIBRATION/OpERATION