PAGE 6 OF 18

0317 IH-2304

TROUBLESHOOTING GUIDE

OPERATING ISSUE

CAUSES

RECOMMENDATIONS

Machine not powering on.

The system is not plugged into a 120VAC outlet.

Plug machine into a 120VAC outlet.

Does not have continuity.

Use a voltmeter to test continuity of the power cord.

Replace the power cord to the machine.

Replace the main circuit breaker.

The frequency drive circuit breaker is not on.

Switch the main circuit breaker on.

Use a voltmeter to test continuity across the

circuit breaker. Does it have continuity?

Replace the main circuit breaker.

It is not receiving the charge.

Use a voltmeter to read input voltage to the frequency

drive. Tighten or replace wiring to the frequency drive(s).

Turntable is malfunctioning.

It is not set high enough.

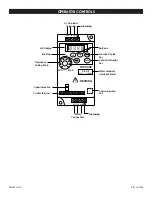

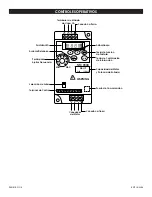

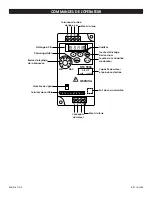

Locate the turntable speed potentiometer dial on the AC

frequency drive.

Adjust potentiometer towards 100% to set speed.

It is not functioning properly.

Step on the foot switch, and use a voltmeter to test for

continuity of the foot switch.

Tighten wiring, replace the foot switch if necessary.

The frequency drive is not functioning (i.e. no

faults displayed).

Remove power to the drive. Wait sixty seconds, and

supply power back.

Refer to frequency drive manufacturer's manual for

specific fault.

The frequency drive is not connected properly

to the motor.

Locate the turntable motor, and use a voltmeter to check

continuity of all motor wires.

Tighten or replace wiring as necessary.

Replace the turntable frequency drive.

WARNING! Make sure that only qualified

personnel perform inspection, troubleshooting

and part replacement.

CAUTION! Disconnect all power including

external control power that may be present

before servicing the frequency drive

controllers. WAIT for three (3) minutes for

the DC bus capacitors to discharge. The

frequency drive controller' display and/or LED's

are not accurate indicators of the absence of

DC bus voltage.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295-5510

uline.com