0411 IH-2957

PAGE 14 OF 17

MAINTENANCE

As with all machinery, proper attention and

maintenance is the key to long component life,

maximum performance, and safe operation. By

spending a few minutes reading and following these

preventive measures, you should reduce the downtime

and prolong the life of your system.

It is important to understand that these maintenance

schedules are minimum recommendations. Anyone

who maintains or services a stretch wrap machine

must first satisfy himself/herself as to the schedules of

preventive maintenance based on cycling operation

and environmental locations.

WARNING! All maintenance operations require

the equipment to be powered down and

locked out for personnel safety.

LOCk-OUT/ TAG-OUT PROCEDURES

Be sure that anyone performing any type of

maintenance on this equipment is familiar with and is

adhering to the lock-out/tag-out procedures set forth by

the General OSHA or the State OSHA guidelines.

VISUAL CHECkS

Visual checks should be conducted at least once per

month:

1. keep the machine and surrounding area as clean

as possible, especially near moving components.

2. Check for loose hardware, especially set screws

located in: sprocket hubs, bearing hubs, and

flanges.

3. Check for oil leaks around the speed reducers.

4. Check for dry seals at the bearings.

5. Check for chain wear and proper tension on the

power roller stretch sprockets. The correct amount of

chain tension can be checked by pulling the chain

taut and having 3/8" slack.

6. Check for loose electrical connections and for

frayed cords and cables. Replace immediately any

damaged cords and cables.

TURNTABLE BELT ADJUSTMENT

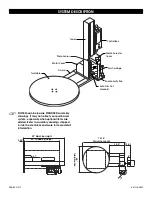

Refer to figure below to adjust the turntable belt. First,

loosen the four motor flange (M10) screws. Turn the

(M10) bolt on the adjuster tab until the belt is tensioned.

Retighten the four motor flange screws.

FILM CARRIAGE LIFT CHAIN ADJUSTMENT

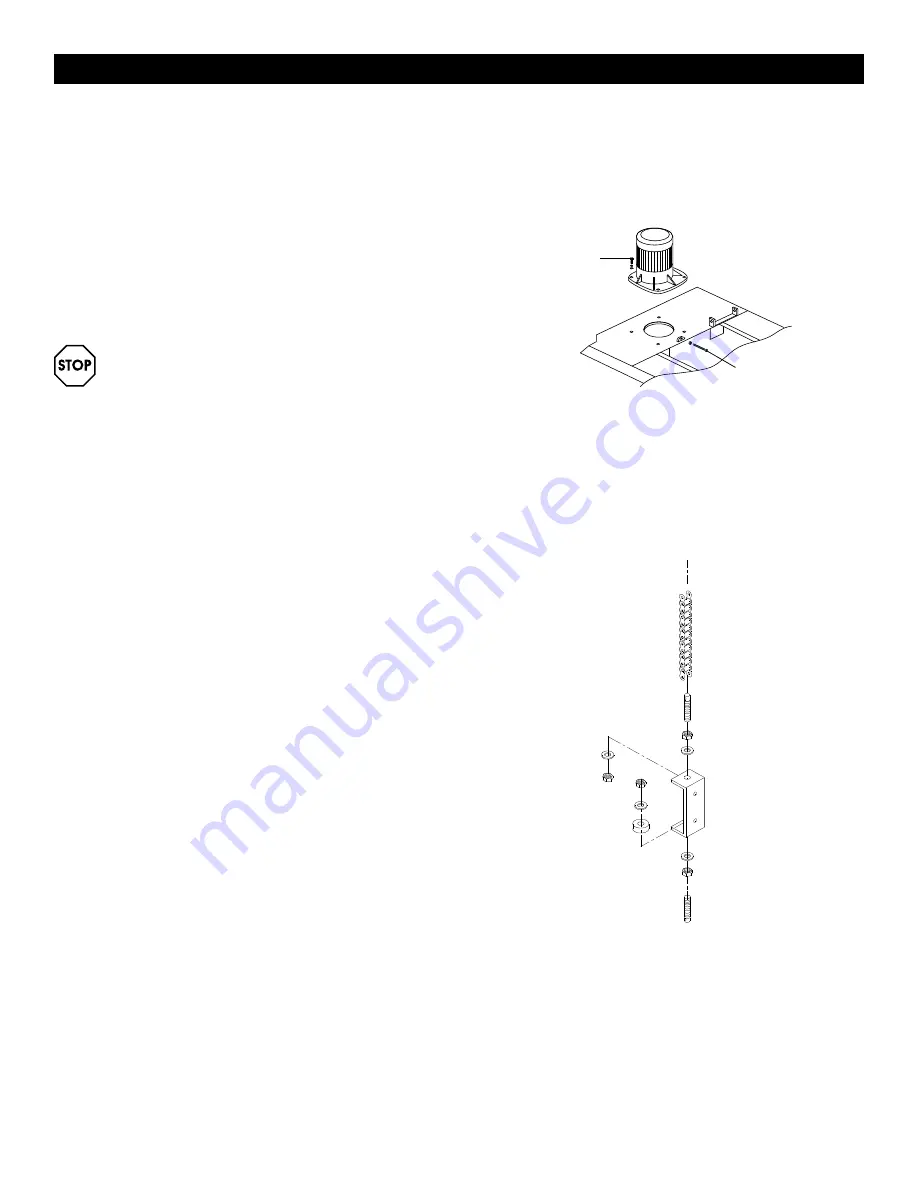

Refer to figure below to adjust the film carriage lift

chain. First, loosen nut (M12) on the adjustment bracket.

Turn the bottom bolt until desired tension is achieved.

Retighten nut (M12). Note that the driving chain

and adjustment bracket should be parallel with the

moveable pulley base.

SPROCkET AND CHAINS

All sprockets should be inspected for wear, and chains

should be checked for proper tension and lubrication

on a periodic basis. Failure to do so will lead to

premature sprocket failure. Any general-purpose chain

lube should be sufficient for lubrication. Replace chain

guards when preventative maintenance is complete.

M10 Screw

M10 Bolt