0411 IH-2957

PAGE 5 OF 17

fREQUENCY DRIVE

An electronic frequency motor drive is a device that

controls the 3-phase AC induction motor’s speed by

varying the frequency of the power sent to the motor.

The Predator Turntable Stretch Wrapper uses Schneider

Electrical Altivar 12 Adjustable Frequency Drives.

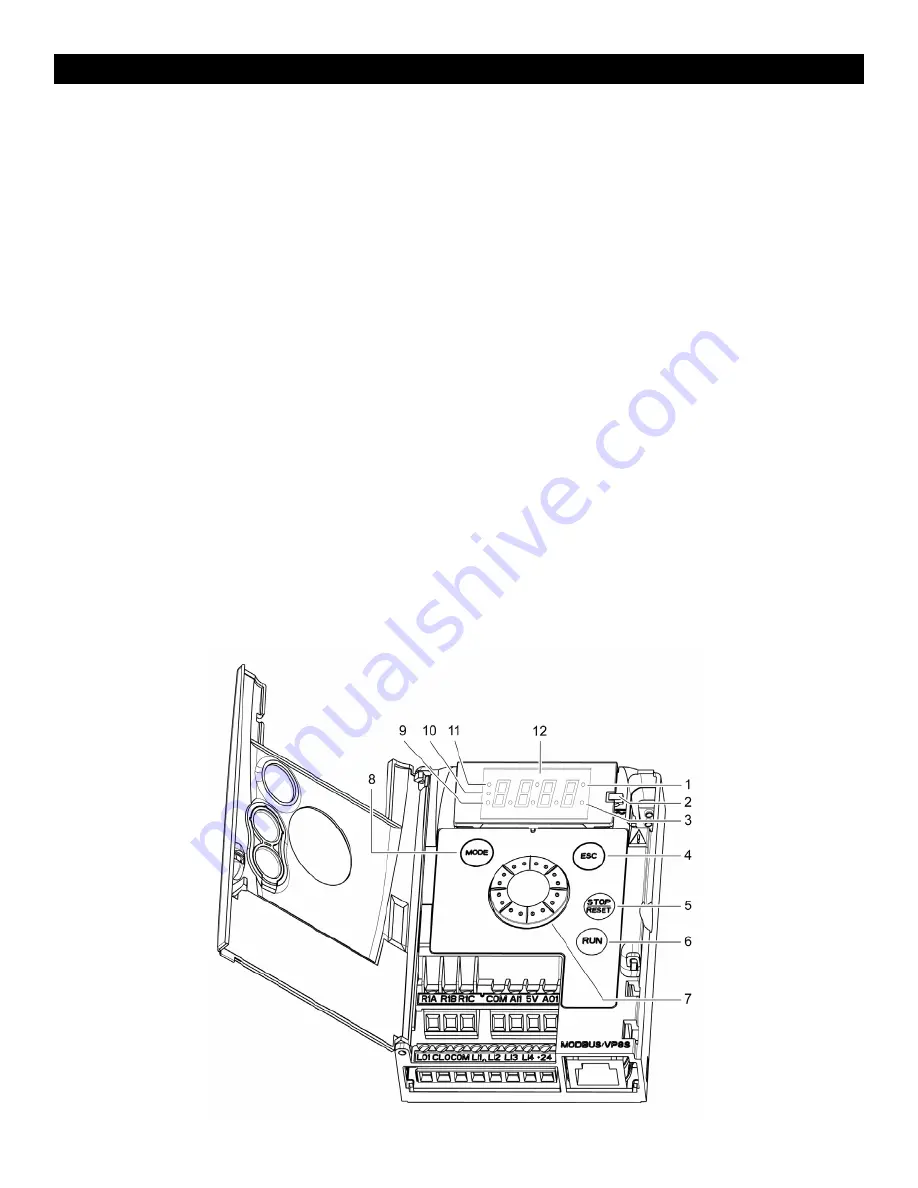

ALTIVAR 12 DIGITAL kEYPAD DESCRIPTION

The digital keypad includes the displays panel and

the keypad. The display panel provides the parameter

display and shows the operation status of the AC

drive. The keypad provides programming and control

interface.

DESCRIPTION:

1. Value LED (a) (b)

2. Charge LED

3. Unit LED (c)

4. ESC button: Exits a menu or parameter, or aborts

the displayed value to return to the previous value

in the memory.

5. STOP button: Stops the motor (could be hidden

by door if function disabled). Important: See

instructions for "RUN/STOP" cover removal.

6. RUN button: Starts running if the function is

configured (could be hidden by door if function

disabled).

7. Jog dial

- For navigation when turned clockwise or

counterclockwise

- and selection / validation when pushed

8. MODE button

Switches between the control/programming modes.

The MODE button is only accessible with the HMI

door open.

9. CONFIGURATION mode LED (b)

10. MONITORING mode LED

11. REFERENCE mode LED

12. Four "7-segment" displays

(a) If illuminated, indicates that a value is displayed,

for example, 0.5 is displayed for "0.5".

(b) When changing a value the configuration mode

LED and the value LED are on steady.

(c) If illuminated, indicates that a unit is displayed,

for example, AMP is displayed for "Amps".