0411 IH-2957

PAGE 6 OF 17

fREQUENCY DRIVE CONTINUED

MENU STRUCTURE

To access the monitoring parameters, press the wheel

on the face of the frequency drive. Using the wheel,

scroll through the list until the display shows Non (Mon)

for monitoring mode. This gives the user access to all the

monitoring parameters.

To access the complete set of drive parameters first

press the wheel to access different modes. Using the

wheel, scroll to "COnF" and press the wheel again; this

will access different sets of parameters. Using the wheel,

scroll to "FULL" and press the wheel; this will give the user

access to the complete parameter set.

ENT

CODE

NAME/DESCRIPTION

UNIT

LFr

External Reference Value:

External keypad or local force mode configured. Forced local reference FLOC set to LCC and forced local

assignment FLO different to nO. Displays the speed reference coming from the remote keypad. This value is not

visible in factory setting.

Hz

rFr

Output Frequency:

This function provides the estimated motor speed. It corresponds to the estimated motor frequency (on the motor

shaft). In standard law the output frequency rFr is equal to stator frequency. In performance law the output

frequency rFr motor speed is equal to the estimated motor speed.

Range: -400 to 400 Hz

Hz

LCr

Motor Current:

Estimation of the effective motor current from phase current measurements with an accuracy of 5%. During DC

injection, the current displayed is the maximum value of current injected in the motor.

A

ULn

Main Voltage:

Line voltage from the point of view of the DC bus, motor running or stopped.

A

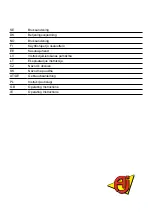

CODE

NAME/DESCRIPTION

StAt

rdY

rUn

ACC

dEc

dCb

CLl

nSt

Obr

CtL

tUn

FSt

nLP

ß Product Status

This parameter shows the state of the drive and motor.

ß Drive ready.

ß Drive running, the last six segments to the right of the code also indicate direction and speed.

ß Acceleration, the last six segments to the right of the code also indicate direction and speed.

ß Deceleration, the last six segments to the right of the code also indicate direction and speed.

ß DC injection braking in progress.

ß Current limit, the four segments located on right down of display are blinking.

ß Freewheel stop control.

ß Auto-adapted deceleration.

ß Controlled stop on mains phase loss.

ß Auto-tuning in progress.

ß Fast stop.

ß No line power. When the control part is energized via the RJ45 connector and there is no power on the main input and

no run order is present.

MONITORING PARAMETERS