PAGE 6 OF 7

0219 IH-7862

MAINTENANCE CONTINUED

SPECIFICATIONS

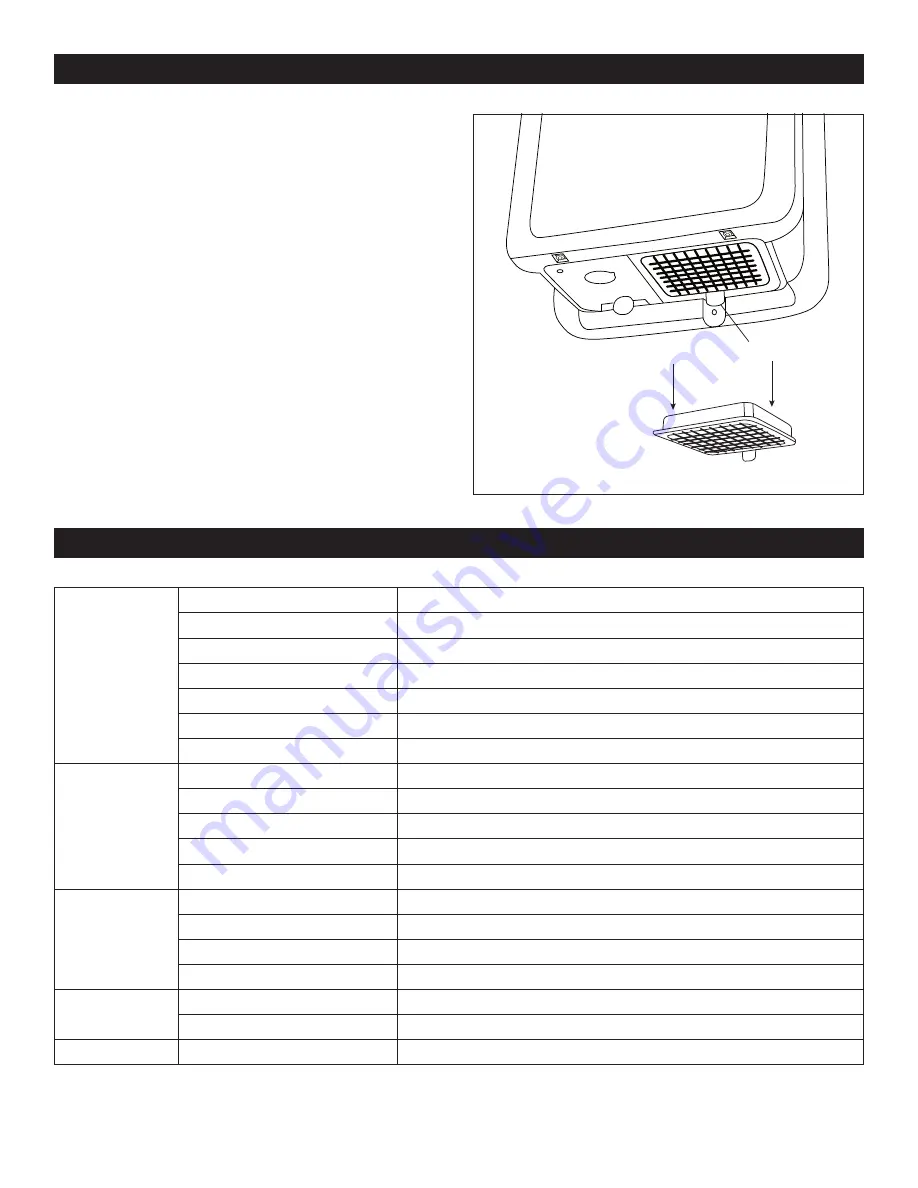

HEPA FILTER

Regularly check the HEPA H13 filter at base of hand

dryer and make sure that it is free of dust or other

particles. Change filter when necessary or at least once

per year.

1. To change filter, pull tab on filter in and down.

Replace with authentic ffuuss HEPA H13 filter.

(See Figure 12).

Every time hand dryer is cleaned, use included wire

brush to clean drain hole.

Figure 12

Electric System

Input Voltage

110-120 V

Frequency

50/60 Hz

Nominal Power

1000 W

Electric Current

9 A

Type of Motor

Universal

Motor Speed

21,500 RPM

Working Temperature

104°F

Manufacturing

Cover Material

ABS (Treated with biomaster silver biocide antibacterial additive.)

Finish

Various Colors

Mounting Bracket

Galvanized Steel

Water Inlet Protection

IPX2

Filter

ffuuss HEPA H13

Operation

Activation

Automatic

Hand Drying Time

12 Seconds

Blocking Time

25 Seconds

Airflow

19.3 gal/s

Logistics

Net Weight

16.4 lbs.

Gross Weight

20.9 lbs.

Box Dimensions

27⁄ x 15⁄ x 11⁄"