www.U-LineService.com

12

11/2006

CO1175 — Ice Maker/Refrigerator

.

5. Insert the screw. Do not over-tighten.

6. Reinstall control knob.

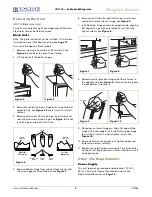

Glass Shelf Installation

1. Carefully remove the glass shelves from the packaging.

2. Slide the shelves onto lower sets of ribs, making sure

the decorative graphics are on the underside of the

shelves. While edge strips go toward the rear and silver

edge strips go toward the front. See

Figure 24

.

Installation Troubleshooting

Problem

Q:

Water is leaking under the unit.

Solution

A:

A water leak under the unit is most likely caused by a bad

connection in the water supply line. Make sure the water

line’s brass fitting is screwed tight to its valve and

threaded correctly. Make sure that plumbers tape was

NOT used; if it was remove all traces before reinstalling.

Initial Start-Up

The unit is shipped with the control preset to a mid-point

setting between 4 and 5. Assure that setting was not

altered in shipment. No other adjustments should be

necessary at this time. For information about Adjusting

the Temperature Control, see the User Manual.

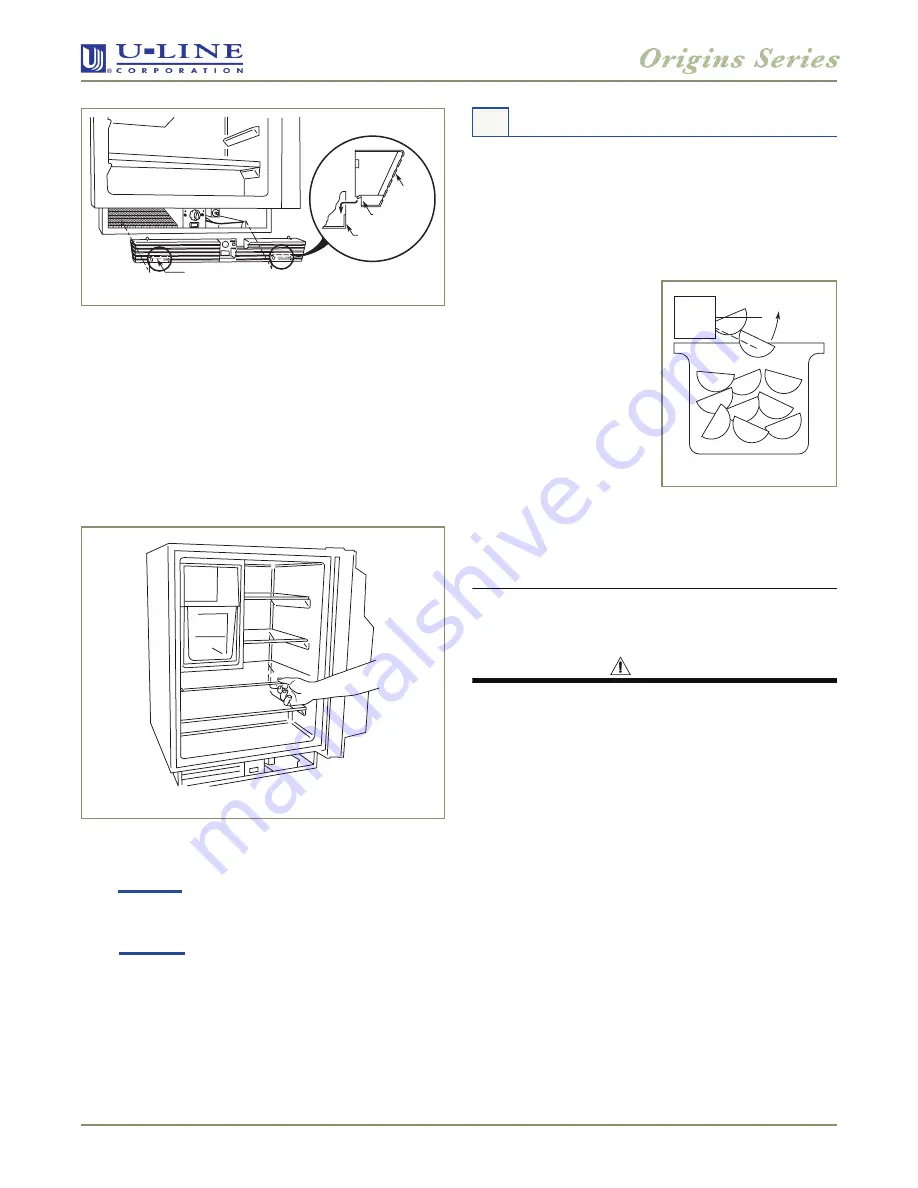

As soon as the ice maker

mold reaches the proper

temperature, the ice maker

mechanism will fill the mold

with water.

Note:

The first cubes may be

small because of air in the

water line. After two hours,

cubes will be standard size.

The ice maker will continue

to produce until the bin is

full. You may interrupt

production by raising the bin

arm into an upright and locked position (see

Figure 25

).

While the bin arm is locked, the unit will maintain

temperature for ice storage.

IMPORTANT

It is possible that dirt or scale will dislodge in the water

line. Always throw away all ice cubes made during the

first twenty-four (24) hours of operation.

CAUTION

The ice bucket MUST be fully inserted to avoid freezing

products in the refrigerator section. The ice bin door must

be fully closed.

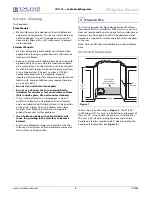

Hook-Hinge

Hook-Hinge

Unit Base

Front Lip

Grille

Figure 23

Figure 24

10 Start-Up for the First Time

Figure 25