u-line.com

USER GUIDE

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

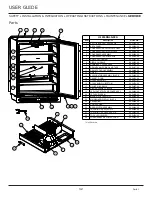

Parts 1

Parts

* Not Pictured

U-1224RGLS-00A

Item

Description

U-Line P/N

1

ANTI TIP BRACKET W/SCREWS

80-54239-00

2

BACK PANEL

80-54204-00

3

COMPRESSOR ELECTRICALS ONLY

80-54149-00

4

COMPRESSOR W/ELECTRICALS

80-54150-00

5

CONDENSER ASSEMBLY

80-54264-00

6

CONDENSER FAN W/SCREWS

80-54014-00

7

CONTROL HOUSING

80-54265-00

8

DISPLAY MODULE

80-54252-00

9

DOOR ASSY, 24 GLASS SS

80-55593-00

10

DRAIN PAN W/TUBING AND TAPE

80-54217-00

11

DRAIN TROUGH ASSEMBLY

80-54499-00

12

DRIER

80-54055-00

13

EVAPORATOR ASSEMBLY, BLACK

80-54262-00

14

GASKET, DOOR

80-54213-00

15

GLASS ASSEMBLY

80-54277-01

16

GLASS SHELF(1) BOTTOM

80-54274-00

17

GRILLE W/SCREWS

80-54267-00

18

HINGE ASSEMBLY, BLACK

80-55595-02

19

LED LIGHT STRIP AND COVER ASSY

80-54000-00

20

LEG LEVELERS (4)

80-54019-00

21

MAGNET W/SCREWS (2)

80-54250-00

22

MAIN BOARD/DISPLAY, BLACK

80-55610-00

23

PACKAGING *

80-54209-00

24

POWER CORD *

80-54171-00

25

REED SWITCH ASSEMBLY

80-54284-00

26

THERMISTOR(1 PC) EL/WP

80-54006-00

27

THERMISTOR COVER AND PIN

80-54023-00

28

TOOL,LEG LEVELER

80-54794-00

29

WIRE HARNESS & POWER CORD *

80-55424-00

11

1

2

7

8

13

9 14 21

15

16

17

18

19

25

26

27

28

3

4

5

6

10

12

20

22

32