u-line.com

27

Troubleshooting

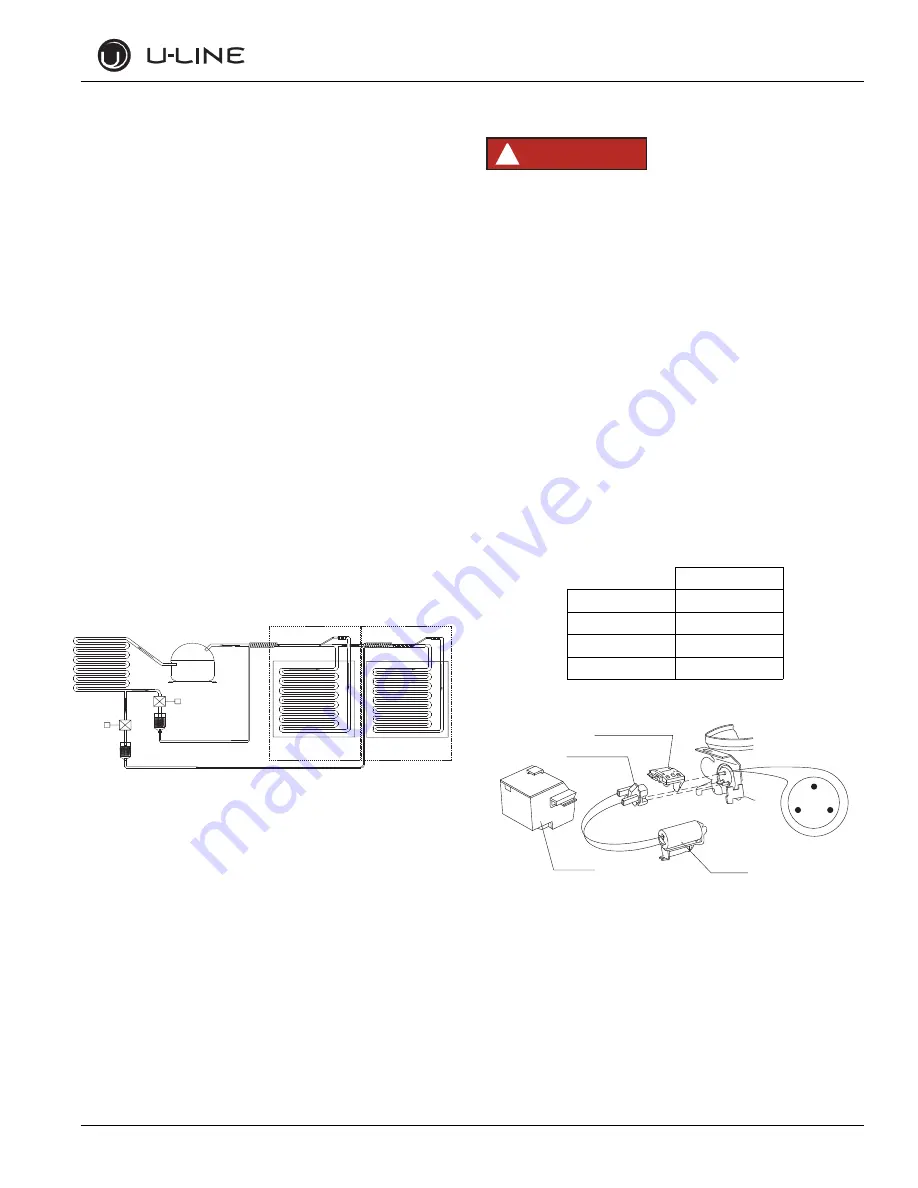

Compressor Information

Cooling process

Refrigerant is pumped from the compressor to the condenser as a

high pressure, high temperature vapor.

As the refrigerant cools in the high pressure condenser, the vapor

condenses to liquid. During this phase change, a great amount of heat

is rejected with the help of the condenser fan.

The liquid then flows through the open solenoid valve to the dryer

where it is strained and filtered.

From the dryer, the refrigerant flows through the capillary tube which

meters the liquid refrigerant to the evaporator.

The pressure of the refrigerant is reduced to the evaporating or low

side pressure.

The reduction of pressure on the liquid refrigerant causes it to boil

or vaporize until it reaches saturation temperature. As the low

temperature refrigerant passes through the evaporator coil, it

continues to absorb a lot of heat, causing the boiling action to

continue until the refrigerant is completely vaporized. It is during this

phase that the most heat is absorbed (the cooling takes place) in the

refrigerator.

The refrigerant vapor leaving the evaporator travels through the

suction line to the compressor inlet. The compressor takes the low

pressure vapor and compresses it, increasing both pressure and

temperature. The hot, high pressure gas is pumped out the discharge

line and into the condenser. The cycle continues.

Compressors

DANGER

!

Electrocution can cause death or serious injury. Burns from hot

or cold surfaces can cause serious injury. Take precautions when

servicing this unit.

• Disconnect the power source.

• Do not stand in standing water when working around

electrical appliances.

• Make sure the surfaces you touch are not hot or frozen.

• Do not touch a bare circuit board unless you are wearing

an anti-static wrist strap that is grounded to an electrical

ground or grounded water pipe.

• Handle circuit boards carefully and avoid touching

components.

To measure the start winding resistance, measure across the C and S

pins.

To measure the run winding resistance, measure across the C and R

pins.

Also check S to R and you should get the sum of the run and start

windings.

To ensure the windings are not shorted, check the S and R to ground.

EMX20CLC

Voltage

230VAC

Frequency

50Hz

Start Winding

34.9 ohms

Run Winding

47.8 ohms

C

S

R

OVERLOAD PROTECTOR

STARTING RELAY

CAPACITOR (IF EQUIPPED)

RELAY COVER

CAPILLARY TUBE

SOLENOID VALVE

SOLENOID VALVE

DRYER

CONDANSER

COMPRESSOR

EVAPORATOR

DRYER

EVAPORATOR

CAPILLARY TUBE

LEFT ZONE

RIGHT ZONE