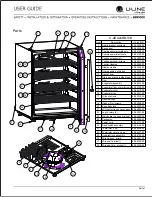

U-ADA24RB-13B

Item

Description

U-Line P/N

1

Anti tip bracket w/screws

80-54239-00

2

Back panel

80-54324-00

3

Compressor electricals only

80-54149-00

4

Compressor w/electricals

80-54150-00

5

Condenser assembly

80-54322-00

6

Condenser fan w/screws

80-54014-00

7

Control Housing

80-54259-00

8

Display module

80-54236-00

9

Door assembly w/hinges

80-54326-00

10 Gasket, door

80-54213-00

11 Drain pan w/double sided tape 80-54323-00

12 Drier

80-54055-00

13 Evaporator assembly

80-54275-00

14 Evaporator fan cover w/screws 80-54320-00

15 Evaporator cover

80-54319-00

16 Evaporator fan

80-54321-00

17 Grille w/screws

80-54325-00

18 Handle w/logo

80-54214-00

19 Hinges (2) w/screws

80-54208-00

20 Keys, babylock

80-54330-00

21 LED light strip and cover assy 80-54000-00

22 Leg Levelers (4)

80-54201-00

23 Main board (no case or wires) 80-54008-00

24 Packaging

80-54209-00

25 Power cord

80-54171-00

26 Reed switch assembly

80-54134-00

27 Thermistor (1 pc)

80-54006-00

28 Thermistor cover and pin

80-54237-00

29 Universal lock assembly

80-54153-00

30 Wire harness, board

80-54251-00

31 Wire shelf w/clips(1)

80-54328-00

32 Wire shelf btm, w/clips(1)

80-54329-00

Parts

Parts 1

1

21

8

7

19

29

14 16

13 15

31

27 28

32

2

22

17

26

10

9

18

5

6

3

12

4

11

23