USER GUIDE

u-line.com

Thermistor

Evaporator Thermistor

If the evaporator thermistor fails, the unit will rely on a

preset defrost timer during defrost cycles. The unit will

otherwise operate normally. Refer to defrost section.

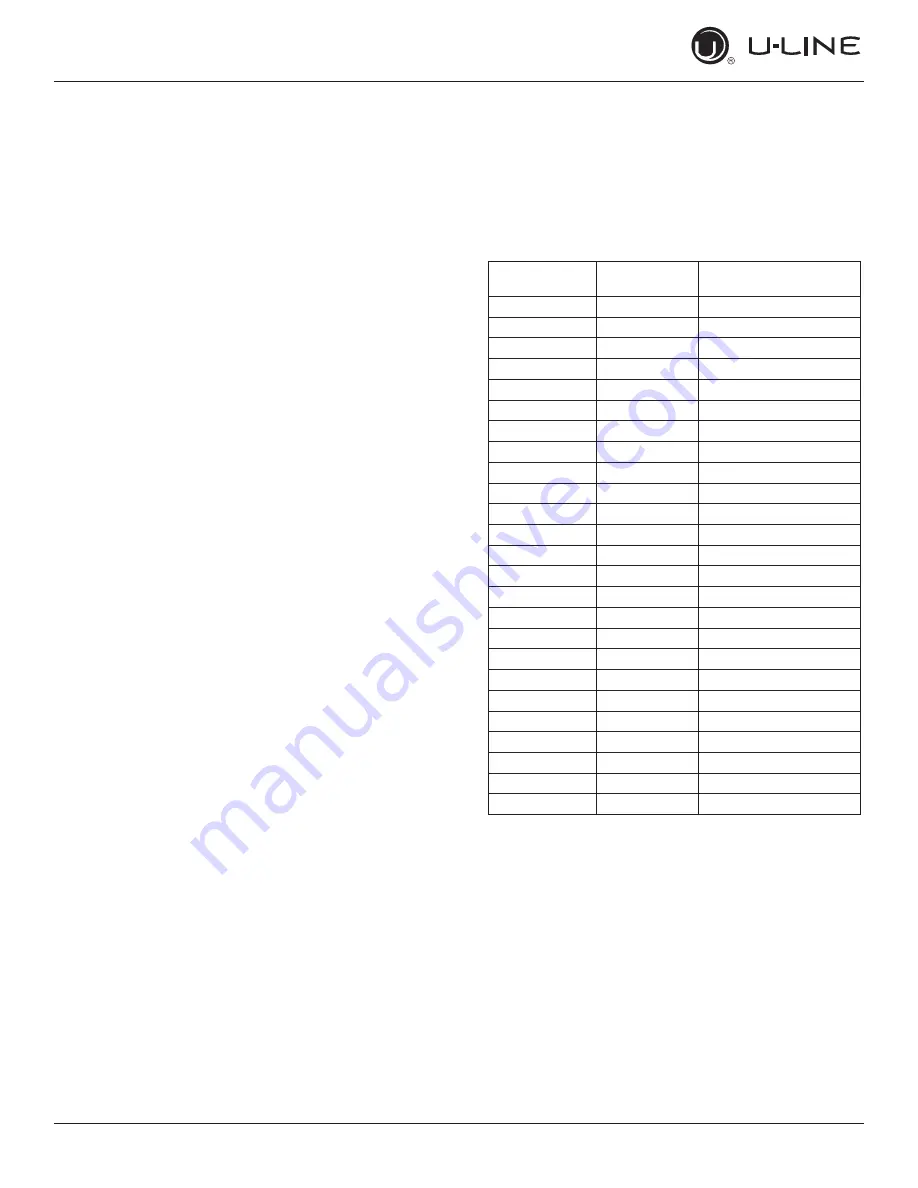

Thermistor Resistance Data

Thermistors

Thermistors are used for various temperature readings.

Thermistors provide reliable temperature readings

using a resistance which varies based on surrounding

temperatures. If a faulty thermistor is suspected it may be

tested using an accurate ohmmeter.

Both thermistors in the unit are identical. If a thermistor

is suspected of being defective, the resistance can be

verified. Place the thermistor in an ice water bath, the

resistance should read 16.1k Ohms +/-5% on your meter.

Thermistor connections must be kept clean. A thermistor

connection that has become corroded can cause resistance

values from the thermistor to change as they pass through

a dirty connection to the board.

It is for that reason that we apply dielectric grease to all of

our thermistor connections. Dielectric grease will help to

keep thermistor connections clean and dry.

If you change a thermistor in the unit please re-apply

dielectric grease to the connection. If you encounter

a dirty thermistor connection, you should replace the

thermistor and the thermistor harness.

Thermistor error information can be found in the Control

Operations - Service section.

This unit has

two

thermistors.

Thermistor one (Zone):

Located along the right hand side wall. It is used to

maintain the operating temperature within that zone.

Thermistor two (Evaporator):

Located on the evaporator. It is used for defrost.

THERMISTOR FAILURE

Zone Thermistor

If the zone thermistor in the unit fails, the unit will

continue to cool in a backup mode (Self Preservation

Mode) to preserve the integrity of the contents. The unit

will otherwise operate normally.

USER GUIDE

u-line.com

Thermistor

Thermistors are used for various temperature readings.

Thermistors provide reliable temperature readings using a

resistance which varies based on surrounding temperatures.

If a faulty thermistor is suspected, it may be tested using

an accurate ohmmeter.

Thermistor connections must be kept clean. A thermistor

connection that has become corroded can cause resistance

values from the thermistor to change as they pass through

a dirty connection to the board.

It is for that reason that we apply dielectric grease to all of

our thermistor connections. Dielectric grease will help to

keep thermistor connections clean and dry.

If you change a thermistor in the unit, please re-apply

dielectric grease to the connection. If you encounter a dirty

thermistor connection, you should replace the thermistor

and the thermistor harness.

This unit has one thermistor located along the right hand

sidewall of the ice bin. It is used to maintain the ice level in

the bin.

Thermistor Resistance Data

* (+/

-

5%)

Thermistor

Temp (F)

Temp (C)

Nominal Resistance

(OHMS)*

-40

-40

169157

-31

-35

121795

-22

-30

88766

-13

-25

65333

-4

-20

48614

5

-15

36503

14

-10

27681

23

-5

21166

32

0

16330

41

5

12696

50

10

9951

59

15

7855

68

20

6246

77

25

5000

86

30

4029

95

35

3266

104

40

2665

113

45

2186

122

50

1803

131

55

1495

140

60

1247

149

65

1044

158

70

879

167

75

743

176

80

631

45