USER GUIDE

u-line.com

Troubleshooting Extended

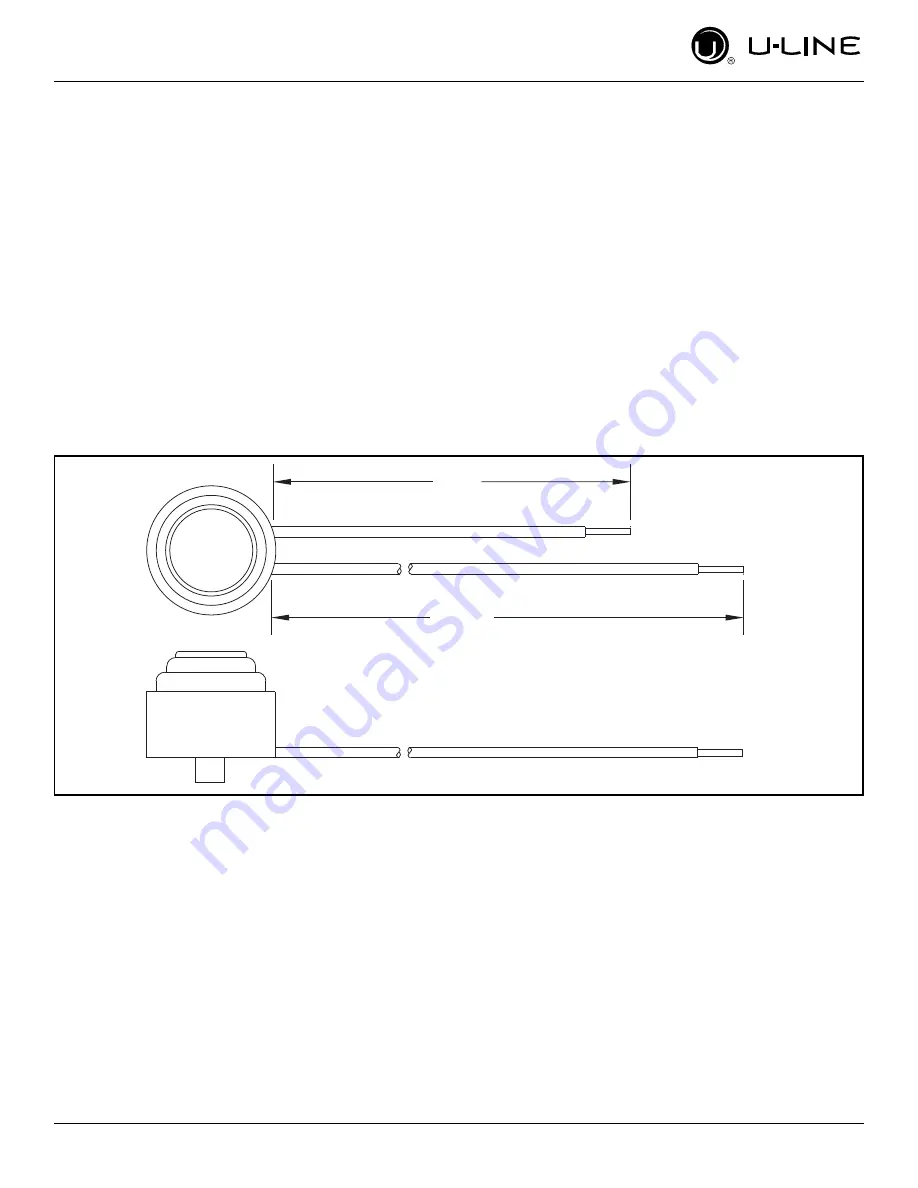

LIMIT SWITCH SPECIFICATIONS

• Normally closed Bi-metal switch

• Open temperature: 104°F

• Close temperature: 83°F

The function of this switch is to open in the event of an

overheating condition. This bi-metal thermostat is

normally closed and does not initiate the ice harvest

cycle. The ice harvest cycle is initiated by a double throw,

single pole temperature located remotely from the ice

maker assembly.

Figure 6. Limit Switch

28.12

3.00

183-10

40