USER GUIDE

u-line.com

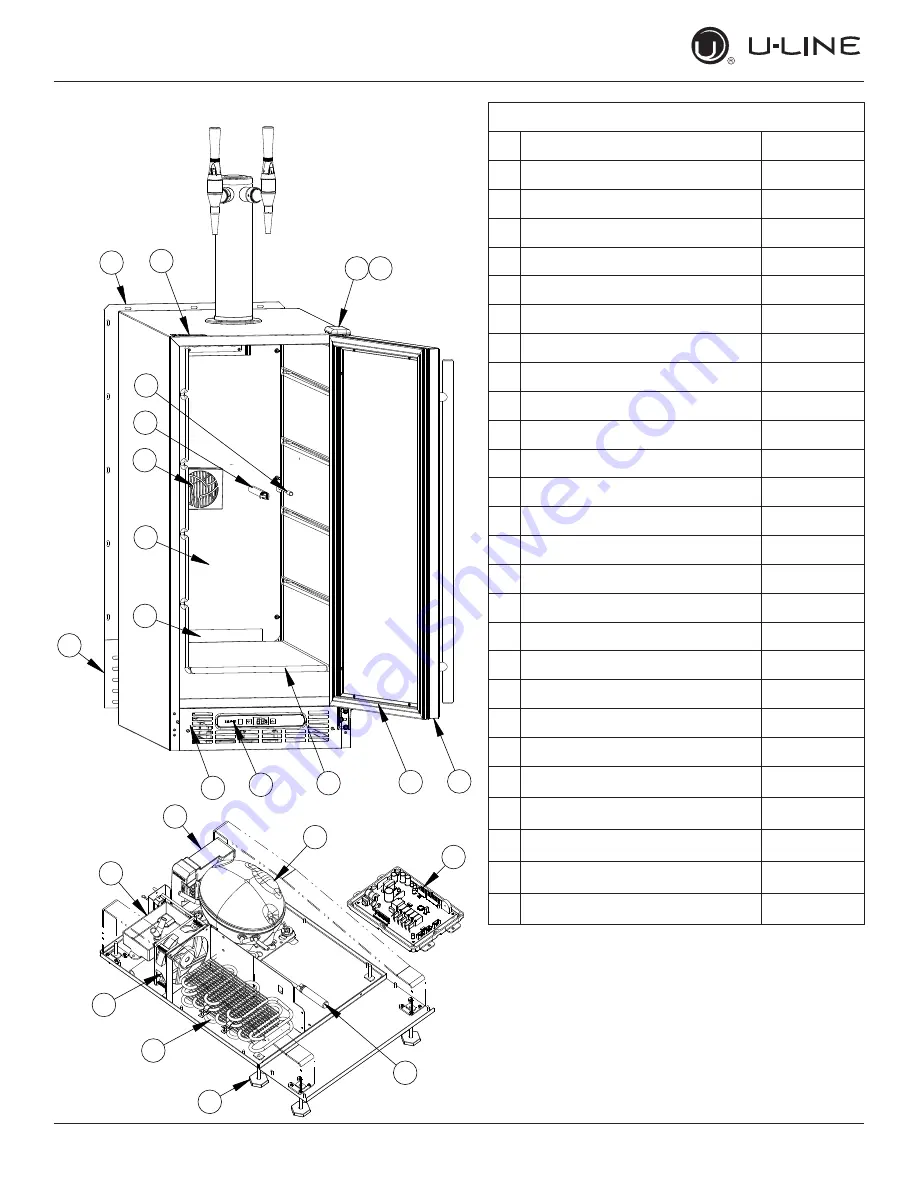

Parts

UHDE215-SS03A

1

ANTI-TIP BRACKET

80-54221-00

2

BACK PANEL, 2 PCS, 15"

80-55559-00

3

COMPRESSOR ASSEMBLY

80-55548-00

4

CONDENSER ASSEMBLY

80-55453-00

5

CONDENSER FAN

80-54014-00

6

CONTROL ASSEMBLY

80-55552-01

7

DOOR

80-55560-00

8

DRAIN PAN

80-54524-00

9

DRAIN TROUGH*

80-55455-00

10

DRIER

80-54055-00

11

DROP IN INVERTER, 120V

80-55569-00

12

EVAPORATOR ASSEMBLY

80-55458-00

13

EVAPORATOR COVER

80-55561-00

14

EVAPORATOR FAN W/COVER

80-54151-00

15

GASKET, DOOR

80-55264-00

16

GRILLE ASSEMBLY

80-55562-00

17

HINGE ASSEMBLY

80-55433-00

18

HINGE COVER

80-55499-00

19

LEG LEVELERS (4)

80-54019-00

20

MAIN BOARD

80-55420-00

21

PACKAGING*

80-55563-00

22

POWER CORD, EXTERNAL*

80-55278-00

23

POWER CORD, INTERNAL*

80-55553-00

24

SHELF LINER

80-55564-00

25

THERMISTOR (1)

80-54006-00

26

THERMISTOR COVER AND PIN

80-54023-00

27

WIRE HARNESS*

80-55402-00

2

2

17 18

1

13

14

26

25

12

6

16

24

8

11

20

3

15

7

4

19

5

10

*NOT SHOWN

Parts

35