USER GUIDE

Environmental Requirements

u-line.com

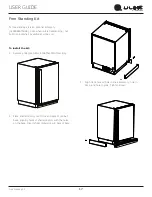

Environmental Requirements

This model is intended for indoor/interior applications only

and is not to be used in installations that are open/

exposed to natural elements.

This unit is designed to operate between 50°F (10°C) and

100°F (38°C). Higher ambient temperatures may reduce

the unit’s ability to reach low temperatures and/or reduce

ice production on applicable models.

For best performance, keep the unit out of direct sunlight

and away from heat generating equipment.

In climates where high humidity and dew points are

present, condensation may appear on outside surfaces.

This is considered normal. The condensation will

evaporate when the humidity drops.

CAUTION

!

Damages caused by ambient temperatures of

40°F (4°C) or below are not covered by the

warranty.

6