36

GB

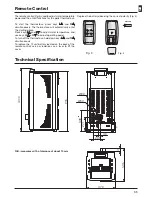

PARAMETER

M. UNITS

NSAT150

Heat input

kW

14,79

Nominal heat output

kW

13,84

Reduced heat output

kW

5,04

Water heat output

kW

10,53

Reduced water heat output

kW

3,81

CO concentration at nominal reference (13% O

2

)

mg/m

3

230,7

CO concentration at reduced reference (13% O

2

)

mg/m

3

299,2

Nominal efficiency

%

93,54

Reduced efficiency

%

96,29

Pellet consumption (min-max)

Kg/h

1,067 - 3,017

Heated surface

mc

270

Flue gas flow rate (min-max)

g/s

4,3 - 8,5

Draft (min-max)

Pa

10 - 12

Flue gas temperature (min-max)

°C

63 - 124,8

Boiler water

litri

17

Maximum working pressure

Bar

1,5

Tank capacity

Kg

17

Smoke outlet tube

mm

80

Diameter air intake

mm

50

Connecting health

Inch

3/4

Nominal voltage

V

230

Nominal frequency

Hz

50

Power consumption max

W

350

Thermostove weight

Kg

130

N° Test Report

K 11952013T1

Summary of Contents for 001143

Page 27: ...55 GB NOTES Cod 001143 ...

Page 28: ...56 GB NOTES Cod 001143 ...