70

EMP

Installation & Service Manual

109529-03 - 11/19

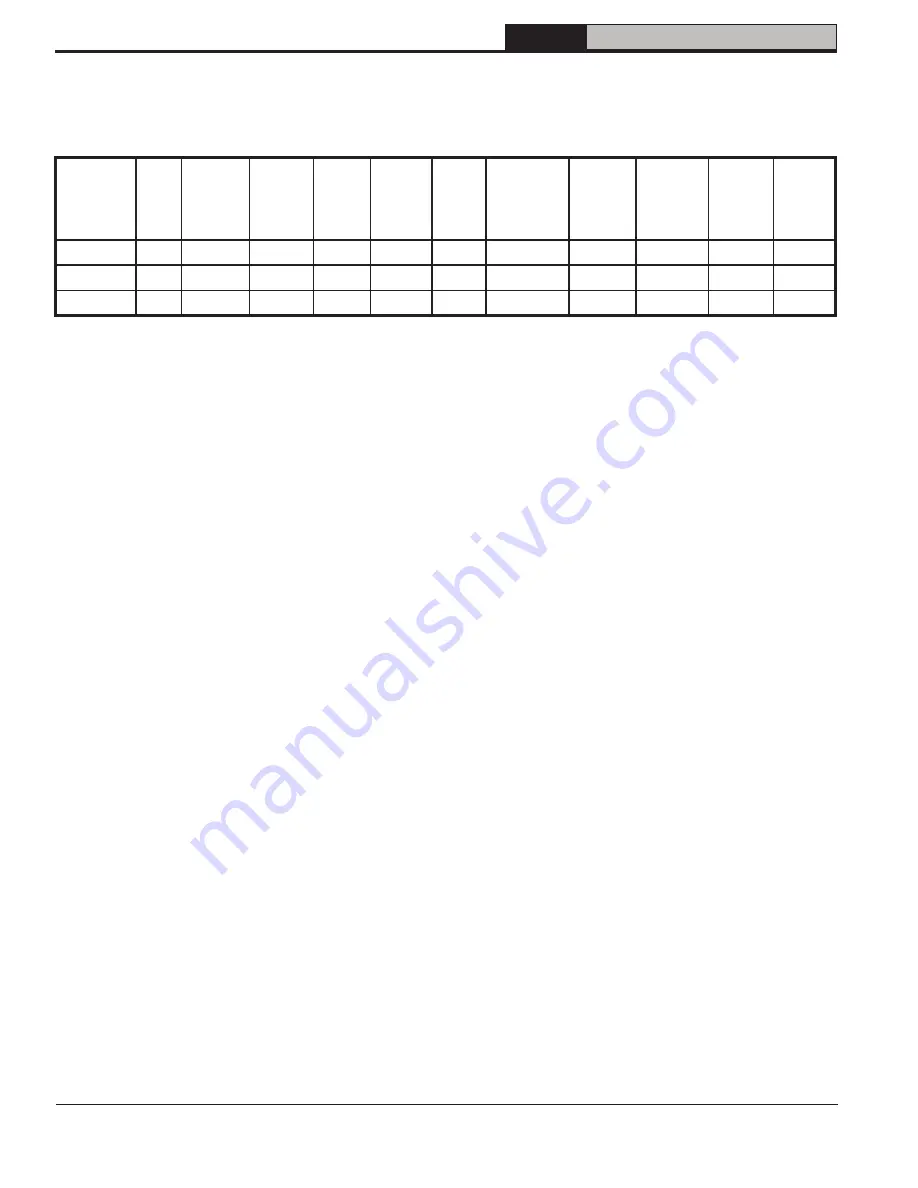

Boiler Model

Burner

Input

(GPH)

Head /Air

Adjustment

(setting)

Nozzle

Pump

Pressure

(PSI)

Approx.

Shipped

CO

2

(%)

Baffle

Location

(pass)

Approx. Stack

Temp. Increase

Without Baffles

°F

(2)

Baffles

IN

Minimum

Overfire

Pressure

(" w.c.)

(3)

Baffles OUT

Minimum

Overfire

Pressure

(" w.c.)

(3)

Baffles

IN

Minimum

Breech

Pressure

(" w.c.)

(3)

Baffles

OUT

Minimum

Breech

Pressure

(" w.c.)

(3)

EMP140E

1.00

2.75

0.75 - 60°W

Delavan

180

11.5

2

nd

75

+0.06

+0.045

+0.045

+0.03

EMP182E

1.30

1.00

1.00 - 45°B

Hago

180

11.5

2

nd

70

+0.10

+0.05

+0.08

+0.04

EMP224E

1.60

2.25

1.25 - 45°B

Hago

180

11.5

2

nd

23

+0.07

0

+0.06

+0.02

Notes

(2)

The increased stack temperature with the baffles removed is an approximation, based on a constant supply temperature of 180°F and 11.5% CO

2

.

Actual field values may be different.

(3)

These values are representative for max vent and air intake piping conditions @ 180°F supply water temperature and 11.5% CO

2

. Actual field values

may be different.

(4)

Single stage fuel pump is standard, two-stage fuel pump is optional. Burner manufacturer has preset single stage fuel pump to settings shown in

table above. Two-stage fuel pump is factory set at 140 PSI and must be readjusted to settings shown above during burner start-up.

Table 10: Beckett NX Burner SPECIFICATIONS - Direct Vent

14

Burner Specifications

(continued)