25

VIII. Service Instructions

A.

General

Inspection and service should be conducted annually.

Turn off electrical power and gas supply while

conducting service or maintenance. Follow instructions

TO TURN OFF GAS TO APPLIANCE. See Figure 21.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

B.

Low water cutoff

Clean probe.

1. Drain boiler to point below Tapping "L".

2. Disconnect the (3) wire multipin connector from the

control and disconnect the control's black wire from

the probe's screw terminal.

3. Remove control from probe.

4. Unscrew probe from Tapping "L".

NOTICE

Carefully remove, clean, and reinstall probe.

Platinum guard ring must not be exposed to

rough treatment, or useful life of probe may be

shortened.

5. Remove deposits from probe using diluted

phosphoric acid (H

2

PO

4

) solution, 3 parts water to 1

part phosphoric acid. Normal operation will occur

with up to 0.2 inch of contamination. If scale or

contamination exceeds 0.2 inches clean probe more

frequently.

6. Reinstall probe in Tapping "L". Mount control on

probe. Attach control's black wire to probe's screw

terminal and reconnect the (3) wire multipin

connector to the control.

C.

Water Feeder and Additional Low Water Cut-Off

Refer to manufacturer's instructions.

D.

Vent System

Inspect for obstructions, soot

accumulation, proper support, and deterioration of pipe,

fittings, and joints.

1. Clean vent terminal screens. Vent terminal must be

free of obstruction, undamaged, with screens

securely in place.

2. Vent terminal and wall thimble (if used) must be

weather-tight.

3. Vent pipe must be full round shape, and show no

damage from impact or excessive temperature.

4. Vent pipe must be supported at minimum 5 foot

intervals and must not sag.

5. All joints must be secure and watertight.

6. Condensate drain must have minimum 6 inch trap

and allow condensate to flow freely. To clean:

a. Disconnect condensate drain from drain fitting.

b. Flush condensate drain with water. Fill trap with

water.

c. Securely fasten condensate drain to drain fitting,

providing gas-tight and watertight seal.

7. If vent pipe must be disassembled for removal of

obstructions or resealing of joint, see Venting

Section.

E.

Boiler Flue Passages.

Inspect for blockage or soot

accumulation.

1. Remove Main Burners.

a. Disconnect Pilot Tubing from Gas Valve.

b. Disconnect Igniter/Sensor Wire and Pilot Ground

Wire from Ignition Module.

c. Disconnect (2) wires to Flame Roll-out Switch.

d. Remove Burner Access Panel.

e. Mark manifold with location of Main Burner

with Pilot Bracket.

f. Hold Main Burner on throat. Lift slightly to clear

orifice. Pull Main Burner from combustion

chamber. Main Burner with Pilot Bracket can

only be removed by lifting at 45° angle after

adjacent Main Burner to right is removed.

2. Disconnect Junction Box to Vestibule Wiring

Harness from Blower.

3. Remove (4) locknuts securing vent connector. See

Figure 7. Disconnect vent connector and vent pipe

from blower outlet.

4. Remove Jacket Top Panels.

5. Disconnect Silicone Tubing from Canopy. Pull

tubing through Blower Access Panel into vestibule.

6. Remove Blower Access Panel.

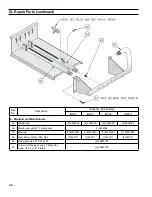

7. Loosen (4) carriage bolts. Remove Canopy/Blower

Assembly.

8. Remove Gasket and Flue Gas Baffles. Inspect Flue

Baffles for deterioration.

Summary of Contents for INDEPENDENCE IN3PV

Page 7: ...7 Figure 4 Steam Piping IN3PV Figure 3 Trim Installation III Steam Piping and Trim continued...

Page 29: ...29 SERVICE RECORD DATE SERVICE PERFORMED...

Page 42: ...42 SERVICE RECORD DATE SERVICE PERFORMED...

Page 43: ...43 SERVICE RECORD DATE SERVICE PERFORMED...

Page 44: ...44 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...