26

Figure 22: Cleaning Boiler Flue Passages

9. Inspect flue passages. Clean with flue brush. See

Figure 22.

10. Inspect heating surface in combustion chamber.

Clean with straight handle wire brush.

12. Install Flue Gas Baffles.

13. Install new Gasket (Key No. 2E). Do not reuse

existing material.

14. Install Canopy/Blower Assembly. Tighten Carriage

Bolts to fully compress Gasket.

15. Install Blower Access Panel.

16. Connect Silicone Tubing between Pressure Fitting

on Canopy Assembly and Pressure Switch. Route

through bushings in Blower Access Panel and

Canopy Assembly.

17. Install Jacket Top Panels.

18. Connect vent system. See Figure 7.

19. Connect Blower to Junction Box to Vestibule Wiring

Harness.

F.

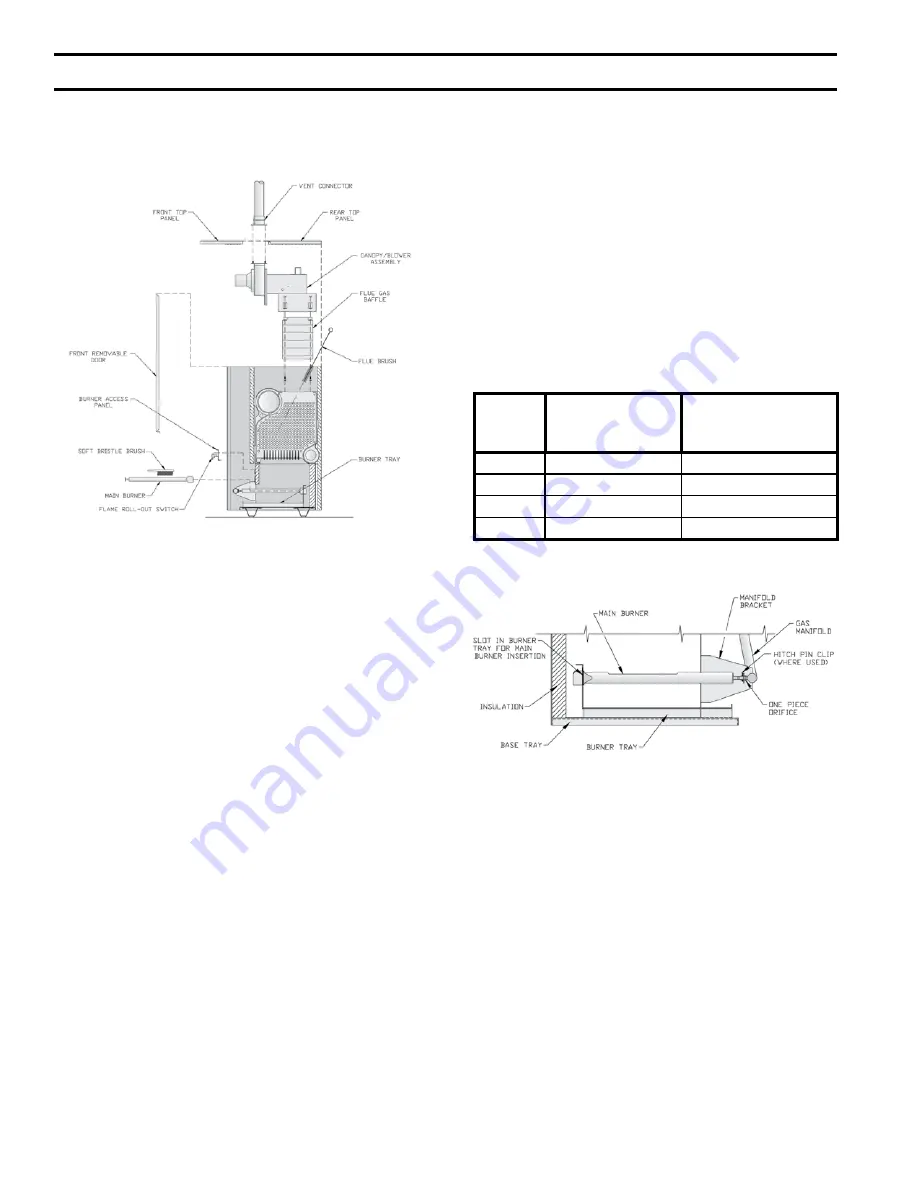

Main Burners and Firebox

1. Vacuum firebox. Exercise care - do not damage base

insulation.

2. Clean main burners. Brush top of burners with soft

bristle brush. Vacuum to remove any dirt and lint.

3. Vacuum tip of pilot burner.

4. Check gas orifices for lint and dirt. Clean as

necessary.

5. Install main burners by reversing procedure to

remove burners.

a. Pilot burner must be installed in original

location. See Table 14.

b. Main burners must be properly secured in burner

tray slot at rear of firebox and over gas orifice.

See Figure 23.

c. Pilot gas supply, igniter/sensor cable and ground

wire must be reconnected.

d. Burner access panel must be securely in place.

e. Flame rollout switch wires must be reconnected.

Table 14: Pilot Burner Location

Figure 23: Main Burner Installation

Boiler

Model

Main Burner with

60° Pilot Bracket *

Pilot Burner Located

Between Main

Burners *

IN3PV

1

1 & 2

IN4PV

2

2 & 3

IN5PV

3

3 & 4

IN6PV

4

4 & 5

* Main burners numbered left to right as viewed from front

of boiler.

VIII. Service Instructions (continued)

G.

Check operation.

Follow steps B through L from

Section VII: System Start-up.

H.

Procedure for Measuring Fan Inlet Pressure

(vacuum),

See Figure 24.

1. With boiler off, remove hose at pressure switch.

2. With Tee and ¼ inch aluminum stubs, connect water

manometer as shown with additional tubing.

3. Start boiler and read Pressure on Manometer when

boiler water temperature reaches operating

temperature. Refer to Table 15 for minimum

readings.

NOTE: If switch drops-out before boiler reaches

temperature or if pressure readings are below

minimums shown in Table 15, check for cracks in

hose or contact your nearest U.S. Boiler Company

representative.

Summary of Contents for INDEPENDENCE IN3PV

Page 7: ...7 Figure 4 Steam Piping IN3PV Figure 3 Trim Installation III Steam Piping and Trim continued...

Page 29: ...29 SERVICE RECORD DATE SERVICE PERFORMED...

Page 42: ...42 SERVICE RECORD DATE SERVICE PERFORMED...

Page 43: ...43 SERVICE RECORD DATE SERVICE PERFORMED...

Page 44: ...44 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...