42

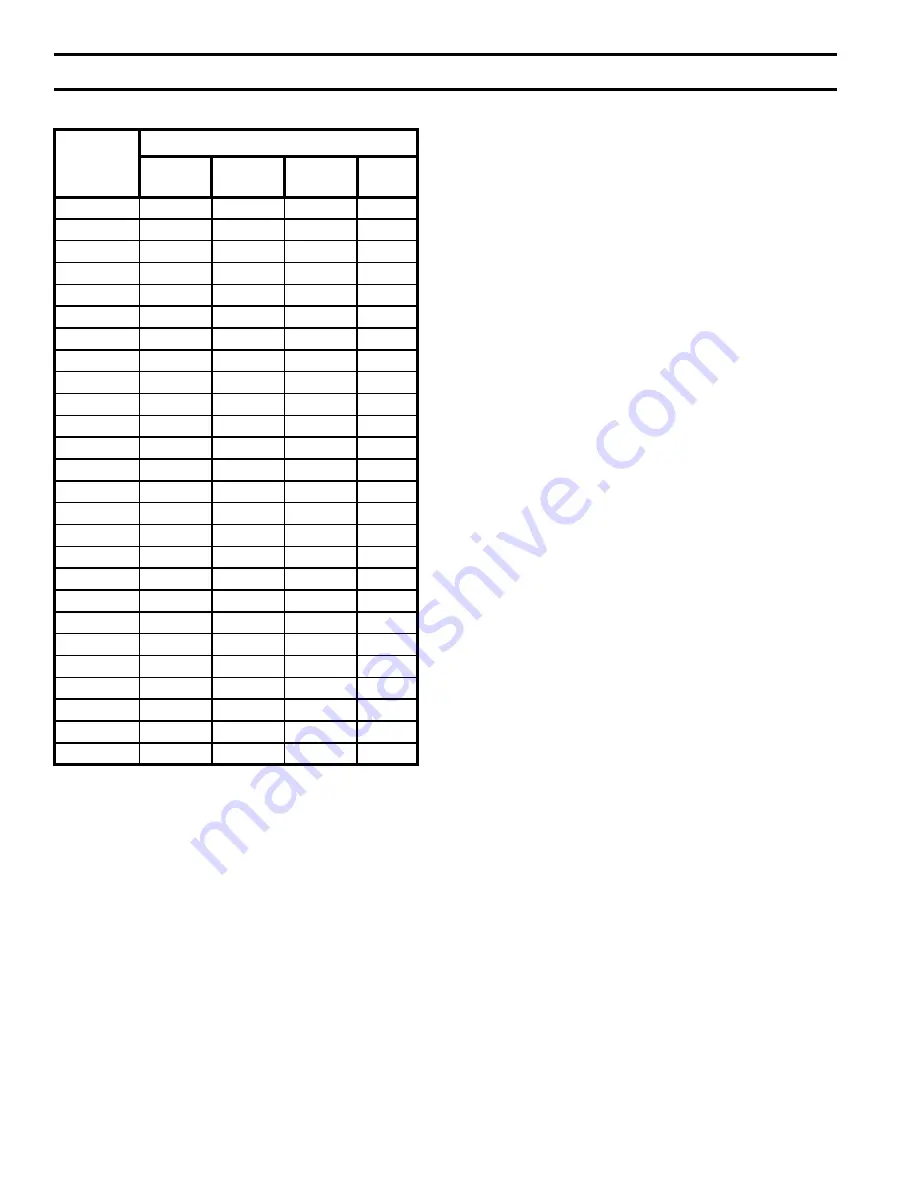

Table 10: Input Rate

APPLIANCE. See Figure 38, 39 or 40.

Drain boiler and system piping.

h. Remove drain valve. Thoroughly wash boiler

water passages with high pressure spray through

drain valve tapping.

i. Reinstall drain valve in Tapping "F". See

Figures 1 and 2.

3. Second Boil-out for Stubborn Cases. If all oil and

grease is not removed a second boilout using surface

blow-off is necessary.

a. Run 1 NPT pipe from Surface Blow-Off Tapping

"L" to open drain. Do not install shut-off valve or

other restriction. See Figure 2.

b. Fill boiler to top of gauge glass.

c. Remove safety valve.

d. Pour recommended boil-out compound into

boiler through safety valve opening.

e. Reinstall safety valve in Tapping "E" with

spindle in vertical position. See Figures 1 and 2.

f. Follow Lighting or Operating Instructions to

place boiler in operation. See Figure 38, 39 or

40. Boil water for approximately 5 hours

without producing steam.

g. Open boiler fill shut-off valve to produce steady

trickle of water from surface blow-off pipe.

Continue boil-out for several hours until surface

blow-off water runs clear.

h. Follow instructions TO TURN OFF GAS TO

APPLIANCE. See Figure 38, 39 or 40. Drain

boiler and system piping.

i. Remove drain valve. Thoroughly wash boiler

water passages with high pressure spray through

drain valve tapping.

j. Fill boiler to normal waterline. If water in gauge

glass is not clear, repeat procedure starting at

step b.

k. Remove surface blow-off piping. Install 1 NPT

plug in Tapping "L". See Figure 2.

4. Add Boiler Water Treatment.

a. Remove safety valve.

b. Pour recommended compound into boiler

through safety valve opening.

c. Reinstall safety valve in Tapping "E" with

spindle in vertical position. See Figures 1 and 2.

d. Follow Lighting or Operating Instructions to

place boiler in operation. See Figure 38, 39 or

40.

e. Boil water or heat water to 180°F.

f. Measure boiler water alkalinity. pH should be

between 7 and 11. Add recommended water

treatment chemicals, if necessary, to bring the pH

within the specified range.

5. If unsteady water line, foaming or priming persist:

a. Follow Lighting or Operating Instructions to

place boiler in operation. See Figure 38, 39 or

40.

b. Install gate valve (shut-off valve) in Hartford

Loop. Install drain valves in return main and at

boiler. See Figure 21.

c. Connect hoses from drain valves to floor drain.

Close gate valve in Hartford Loop. Open drain

valve in return main.

d. Fill boiler to normal water line. Follow Lighting

or Operating Instructions to place boiler in

operation. See Figure 38, 39 or 40.

e. Operate boiler for at least 30 minutes after

condensate begins to run hot. Follow instructions

TO TURN OFF GAS TO APPLIANCE. See

Seconds

for One

Revolution

Size of Gas Meter Dial

One-Half

Cu. Ft.

One

Cu. Ft.

Two

Cu. Ft.

Five

Cu. Ft.

30

60

120

240

600

32

56

113

225

563

34

53

106

212

529

36

50

100

200

500

38

47

95

189

474

40

45

90

180

450

42

43

86

172

430

44

41

82

164

410

46

39

78

157

391

48

37

75

150

375

50

36

72

144

360

52

35

69

138

346

54

33

67

133

333

56

32

64

129

321

58

31

62

124

310

60

30

60

120

300

62

29

58

116

290

64

29

56

112

281

66

29

54

109

273

68

28

53

106

265

70

26

51

103

257

72

25

50

100

250

74

24

48

97

243

76

24

47

95

237

78

23

46

92

231

80

22

45

90

225

IX. System Start-up (continued)

Summary of Contents for INDEPENDENCE

Page 4: ...4 Figure 1 Dimensional Drawing...

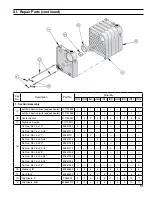

Page 56: ...56 Manifold and 1 Main Burners XI Repair Parts continued...

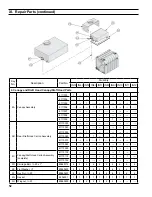

Page 62: ...62 XI Repair Parts continued...

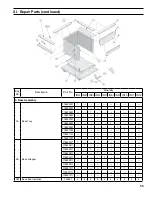

Page 64: ...64 XI Repair Parts continued...

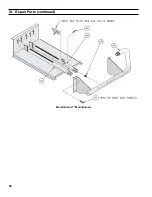

Page 72: ...72 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...