134

107672-01 - 7/17

1)

Continuously

:

a.

Keep the area around the boiler

free from combustible materials, gasoline and other

flammable vapors and liquids.

b.

Keep the area around the combustion air inlet terminal

free from contaminates.

c.

Keep the boiler room ventilation openings

open and unobstructed.

2)

Monthly Inspections

:

a.

Inspect the vent piping and outside air intake piping

to verify they are open, unobstructed and free

from leakage or deterioration. Call the service technician to make repairs if needed.

b.

Inspect the condensate drain system

to verify it is leak tight, open and unobstructed. Call the service

technician if the condensate drain system requires maintenance.

c.

Inspect the water and gas lines

to verify they are free from leaks. Call the service technician to make

repairs

if

required.

4)

Annual Inspections and Service

: In addition to the inspections listed above, the following should be performed by a

service technician once every year.

a.

Follow the procedure

for turning the boiler off found in the Lighting and Operating Instructions (Section XI “Start-

up and Checkout”).

b.

Turn off all power

to the boiler.

c.

Inspect the wiring

to verify the conductors are in good condition and attached securely.

d.

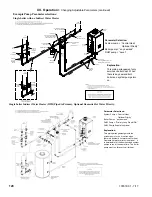

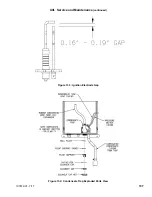

Verify that the gas shutoff

shown in Figure 8.1 is closed.

e.

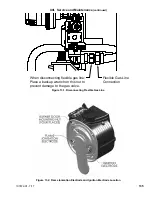

Disconnect the flexible gas line

at the gas valve flare connection (Figure 13.1).

f.

Unplug the electrical connection

to the gas valve.

g.

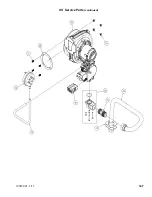

Disconnect the air proving switch tube

from the gas valve outlet tap.

h.

Unplug the power and speed control cables

from the blower.

nOTiCE

Warranty does not cover boiler damage or malfunction if the following steps are not performed at the

intervals specified.

XIII. Service and Maintenance

(continued)

CAUTION / ATTENTION

Electrical Shock Hazard. Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper operation after servicing.

Au moment de l´entretien des commandes, étiquetez tous les fils avant de les débrancher. Les erreurs de

câblage peuvent nuire au bon fonctionnement et être dangereuses. S´assurer que l´appareil fonctionne

adéquatement une fois k´entretien terminé.

Warning

Fire Hazard. Explosion Hazard. Always use a back-up wrench on the flare connection when making

or breaking this connection as shown in Figure 13.1. Failure to do so can cause adjacent threaded

connections to loosen or damage to the gas valve. Check all internal gas piping for leaks any time it is

disconnected or disturbed during servicing.

nOTiCE

Water leaks can cause severe corrosion damage to the boiler or other system components. Immediately

repair any leaks found.

Summary of Contents for K2WT-080B

Page 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

Page 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Page 90: ...90 107672 01 7 17 X Wiring continued...

Page 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Page 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Page 147: ...147 107672 01 7 17 XV Service Parts continued...

Page 151: ...151 107672 01 7 17 XV Service Parts continued...

Page 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Page 162: ...162 107672 01 7 17...

Page 163: ...163 107672 01 7 17...

Page 164: ...164 107672 01 7 17...

Page 165: ...165 107672 01 7 17...

Page 166: ...166 107672 01 7 17...

Page 167: ...167 107672 01 7 17...