66

107672-01 - 7/17

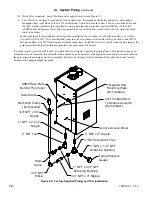

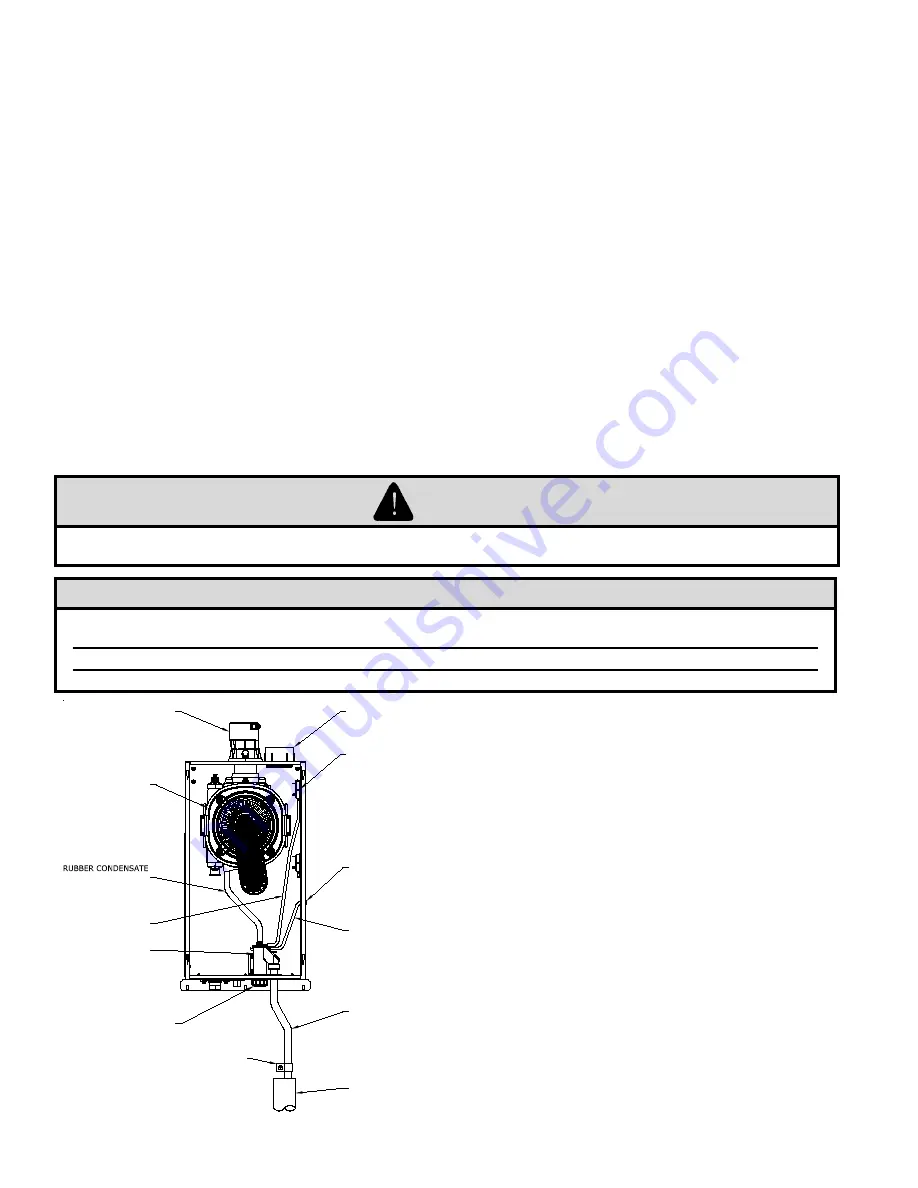

Figure 7.47: Condensate Piping Arrangement

VII. Venting

J. Condensate Trap and Drain Line

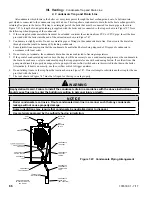

Warning

Asphyxiation Hazard. Failure to install the condensate drain in accordance with the above instructions

could cause flue gas to enter the building, resulting in personal injury or death.

nOTiCE

Boiler condensate is corrosive. Route condensate drain line in a manner such that any condensate

leakage will not cause property damage.

Some jurisdictions may require that condensate be neutralized prior to disposal.

Use materials approved by the authority having jurisdiction.

J. Condensate Trap and Drain Line

All condensate which forms in the boiler or vent system passes through the heat exchanger and out of a bottom drain

port which is connected to the condensate trap with a hose. This trap allows condensate to drain from the heat exchanger while

retaining flue gases in the boiler. This trap is an integral part of the boiler but must be connected to a drain pipe as shown in

Figure 7.47

.

A length of corrugated tubing is supplied with the boiler and is connected to the trap as shown in Figure 747. Note

the following when disposing of the condensate:

1. If the corrugated condensate drain line must be extended, construct the extension from PVC or CPVC pipe.

Insert the hose

provided with the boiler into the end of the extension as shown in Figure 7.47.

2. Condensate is slightly acidic. Do not use metallic pipe or fittings in the condensate drain line. Do not route the drain line

through areas that could be damaged by leaking condensate.

3. Some jurisdictions may require that the condensate be neutralized before being disposed of. Dispose of condensate in

accordance with local codes.

4. Do not route, or terminate, the condensate drain line in areas subjected to freezing temperatures.

5. If the point of condensate disposal is above the trap, it will be necessary to use a condensate pump to move the condensate to

the drain. In such cases, select a condensate pump that is appropriate for use with condensing boilers. If overflow from this

pump would result in property damage, select a pump with an overflow switch and use this switch to shut down the boiler.

Alternatively, if heat is a necessity, use the overflow switch to trigger an alarm.

6. Do not attempt to move the trap from the location shown in Figure 7.47. Do not attempt to substitute another trap for the one

provided with the boiler.

7. The vent shown in Figure 7.47 must be left open for the trap to work properly.

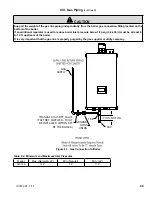

INTAKE AIR

ADAPTER

VENT

ADAPTER

SUMP

PRESSURE

SWITCH

HEAT

EXCHANGER

CONDENSATE

TRAP VENT

HOSE FROM HEAT

EXCHANGER

SUMP PRESSURE

SWITCH TUBING

CONDENSATE

TRAP VENT

TUBING

CONDENSATE

TRAP

CONDENSATE

TRAP CLEANOUT

CORRUGATED

CONDENSATE

TUBING FROM

TRAP

CONDENSATE

DRAIN PIPE

(NOT SUPPLIED)

TUBING CLAMP

(NOT SUPPLIED)

SOME COMPONENTS

IN CABINET OMITTED

FOR CLARITY

Summary of Contents for K2WT-080B

Page 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

Page 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Page 90: ...90 107672 01 7 17 X Wiring continued...

Page 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Page 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Page 147: ...147 107672 01 7 17 XV Service Parts continued...

Page 151: ...151 107672 01 7 17 XV Service Parts continued...

Page 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Page 162: ...162 107672 01 7 17...

Page 163: ...163 107672 01 7 17...

Page 164: ...164 107672 01 7 17...

Page 165: ...165 107672 01 7 17...

Page 166: ...166 107672 01 7 17...

Page 167: ...167 107672 01 7 17...