78

107672-01 - 7/17

IX. System Piping

(continued)

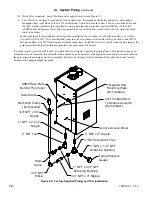

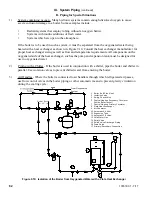

Example – A 120MBH model is to be connected to a heating system as shown in Figure 9.6. A total of 20 ft of straight pipe

will be installed between the boiler and the system loop.

Count all fittings in the boiler loop (shaded in Figure 9.6):

3 90° Elbows

2 Turn in Tee (under boiler- primary-secondary tees not counted)

2 Isolation Valves

1 Y Strainer having a Cv of 30.

Note: Unions, Secondary Connection Tees, and factory supplied fittings are ignored.

Calculate total equivalent length from Table 9.4:

20 ft Straight Pipe + 3 Elbows x 2.8 + 2 Turn in Tee x 5.5 + 2 Valves x 0.6 + 1 Y Strainer x 7.0 = 40.6 Equivalent Feet

Since the total equivalent length is less than 60 ft, flow through boiler loop meets requirements in Table 9.1

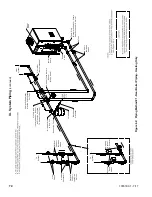

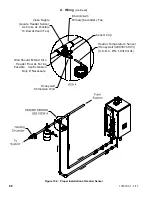

3) Indirect Water Heater Loop Piping – If an indirect water heater is used, install it as shown in Figure 9.3a or 9.3b. Refer to

the indirect water heater installation manual for the proper sizing the indirect water heater loop pump and piping.

4) Hydraulic Separators – Hydraulic separators serve the same purpose as the closely spaced tees connecting the boiler and

system loops in Figure 9.2. They also generally provide effective connection points for automatic air elimination devices

and an expansion tank. These separators are available from several sources and may be used in place of the closely spaced

tees shown in Figure 9.2, 9.3a or 9.3b. When a hydraulic separator is used in place of the tees, the 60 ft equivalent length

limitation still applies. Select a hydraulic separator having 1” or larger boiler connections that is designed for the boiler flow

rates shown in Table 9.1.

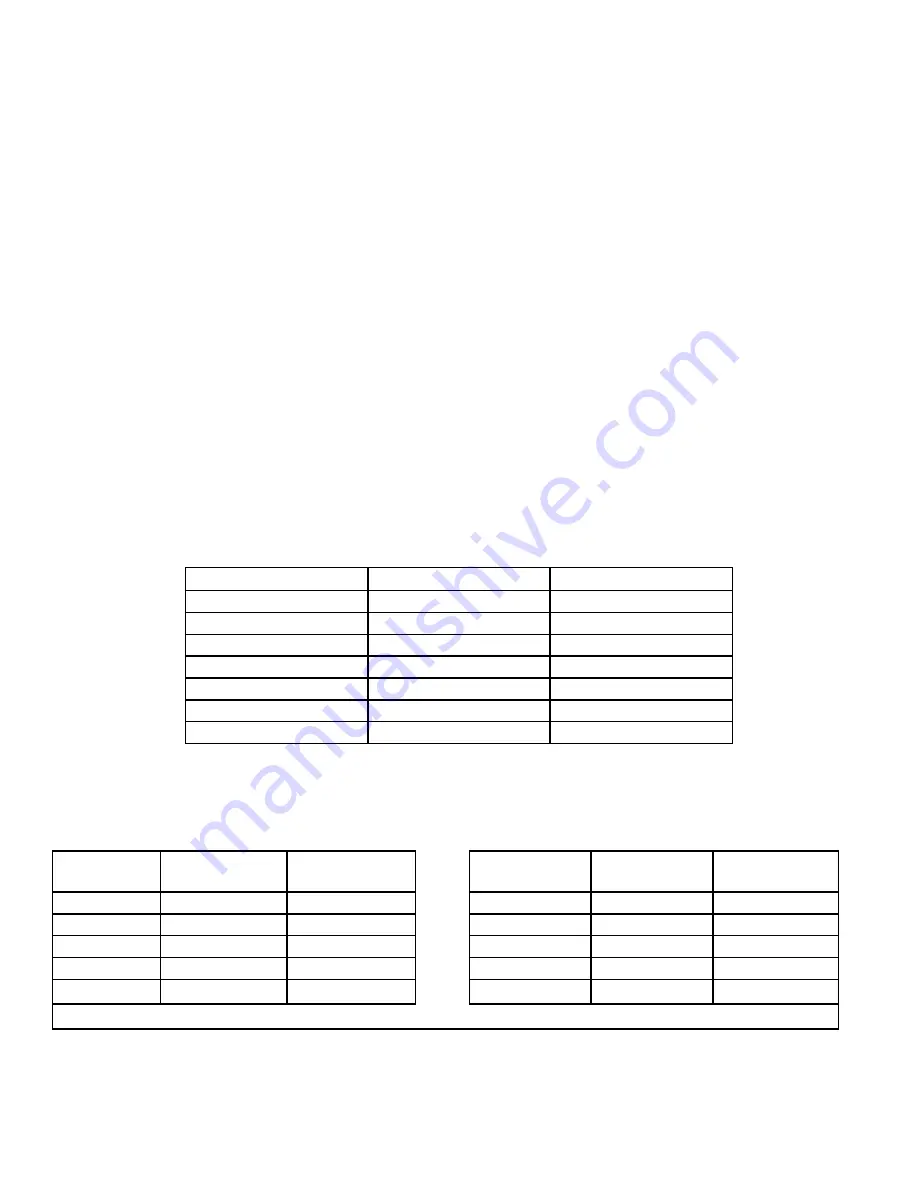

Table 9.4: Equivalent Lengths for Selected Valves and Fittings

(May Be Used for Copper or Threaded Fittings)

Fitting

Pipe Size

Equivalent Length (ft)

90° Elbow

1”

2.8

45° Elbow

1”

1.4

90° Turn in Tee

1”

5.5

Run of Tee

1”

1.8

Gate Valve (Open)

1”

0.7

Full Port Ball Valve

1”

0.7

Y-Strainer*

1”

7.0

* Based on Cv of 20. Pressure drop through strainers varies widely. 7 ft equivalent length

may be assumed for strainers having a published Cv greater than 20.

Table 9.5a: Flow Available with Boiler Loop

Equivalent Length of 30 ft or Less *

Table 9.5b: Flow Available with Boiler Loop

Equivalent Length of 60 ft or Less *

Boiler Model

Approx. Flow

(GPM)

Approx. Rise (°F)

Boiler Model

Approx. Flow

(GPM)

Approx. Rise

(°F)

080

7.5

19

080

7.3

20

100

8.3

22

100

8.0

23

120

9.6

22

120

9.2

24

150

12.9

21

150

11.9

23

180

12.9

25

180

11.9

27

*

For multi-speed pumps, these tables assume pump is set to highest speed.

Summary of Contents for K2WT-080B

Page 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

Page 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Page 90: ...90 107672 01 7 17 X Wiring continued...

Page 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Page 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Page 147: ...147 107672 01 7 17 XV Service Parts continued...

Page 151: ...151 107672 01 7 17 XV Service Parts continued...

Page 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Page 162: ...162 107672 01 7 17...

Page 163: ...163 107672 01 7 17...

Page 164: ...164 107672 01 7 17...

Page 165: ...165 107672 01 7 17...

Page 166: ...166 107672 01 7 17...

Page 167: ...167 107672 01 7 17...