8

107672-01 - 7/17

4. All boilers are shipped from the factory configured for use with natural gas. They may be converted for use with LP gas

(“propane”) using a proper conversion kit per Table 3.1. Use a combustion analyzer and follow all instructions supplied

with conversion kit.

Warning

• Do not attempt to operate this boiler on LP gas without converting it using the proper conversion kit.

• Do not attempt to convert this boiler to LP gas without the use of a combustion analyzer.

• Failure to follow the conversion instructions will result in operation of the boiler at unsafe Carbon

Monoxide (CO) levels and may result in personal injury or loss of life. Improper conversion may also

result in unreliable operation, resulting in property damage.

• Before attempting to operate this boiler at altitudes above 2000 ft., follow instructions shown in

Appendix A of this manual.

nOTiCE

This product must be installed by a licensed plumber or gas fitter when installed within the

Commonwealth of Massachusetts. See Appendix B for additional important information about installing

this product within the Commonwealth of Massachusetts.

IV. Locating the Boiler

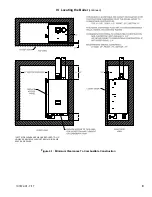

1. Observe the minimum clearances shown in Figure 4.1. These clearances apply to combustible construction as well as

non-combustible walls, floors, ceilings and doors.

2. Note the recommended service clearances in Figure 4.1. These service clearances are recommended, but may be reduced

to the combustible clearances provided:

a. Access to the front of the boiler is provided through a door.

b. Access is provided to the condensate trap located beneath the boiler.

Note that servicing the boiler will become increasingly difficult as these service clearances are reduced.

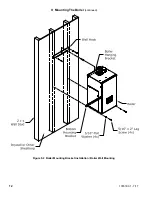

3. Observe the following clearances from piping to combustible construction:

Non-concentric vent (exhaust): ¼”

Air intake piping: 0”

Hot water piping: ¼”

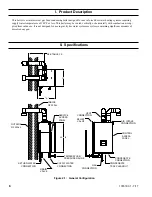

4. The relief valve and gauge must be installed in the location shown in Figure 2.1 and must be in the same space as the

boiler.

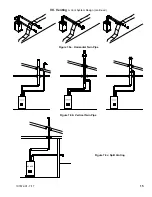

5. The boiler should be located so as to minimize the length of the vent system.

6. The combustion air piping must terminate where outdoor air is available for combustion and away from areas that will

contaminate combustion air. Avoid areas near chemical products containing chlorine, chloride based salts, chloro/fluoro

carbons, paint removers, cleaning solvents and detergents.

III. Before Installing

(continued)

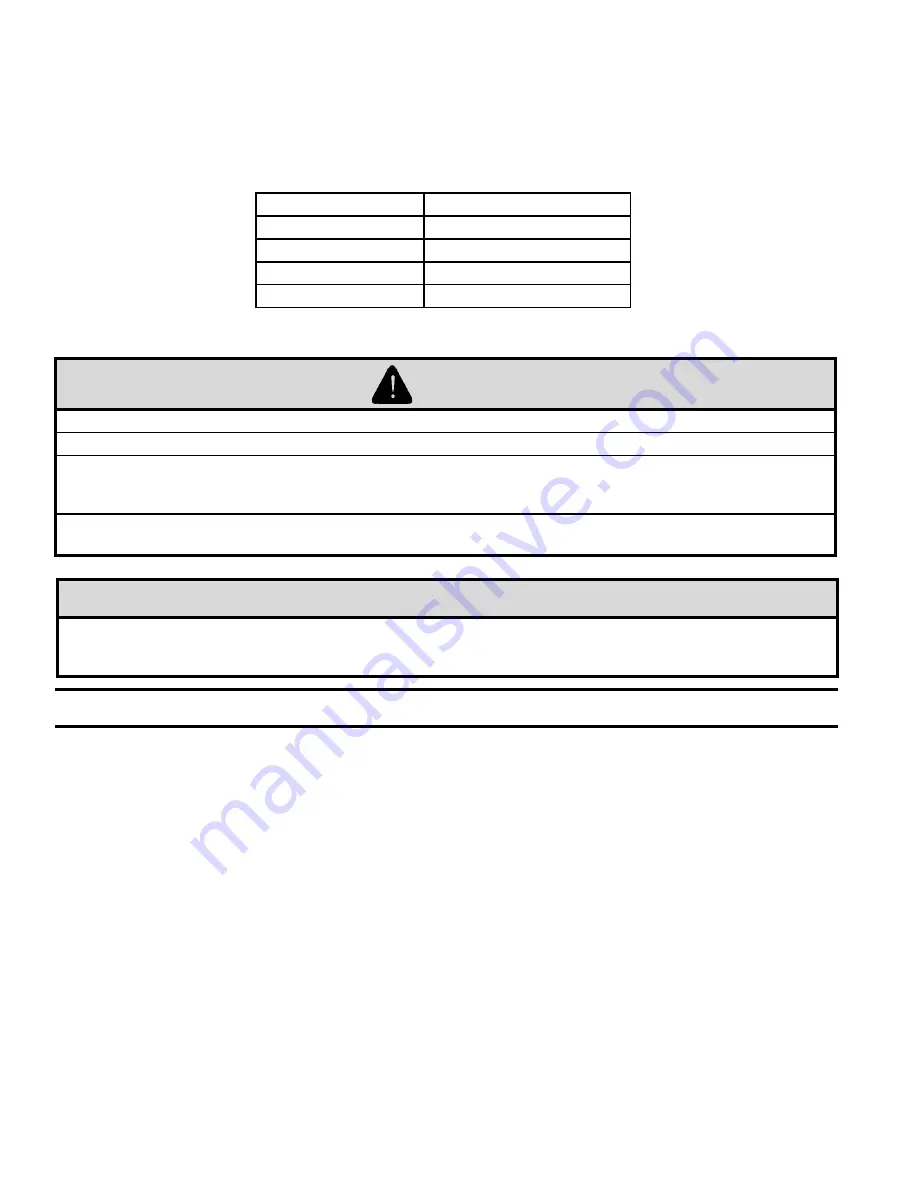

Model Size

LP Conversion Kit

080B-100B

107873-01

120B-150B

107874-01

180B

107875-01

180M

108101-01

Table 3.1: LP Conversion Kits

Summary of Contents for K2WT-080B

Page 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

Page 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Page 90: ...90 107672 01 7 17 X Wiring continued...

Page 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Page 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Page 147: ...147 107672 01 7 17 XV Service Parts continued...

Page 151: ...151 107672 01 7 17 XV Service Parts continued...

Page 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Page 162: ...162 107672 01 7 17...

Page 163: ...163 107672 01 7 17...

Page 164: ...164 107672 01 7 17...

Page 165: ...165 107672 01 7 17...

Page 166: ...166 107672 01 7 17...

Page 167: ...167 107672 01 7 17...