95

107672-01- 7/17

Use the following procedure for initial start-up of the boiler:

1) Verify

that the venting, water piping, gas piping and electrical system are installed properly.

2)

Confirm all electrical, water and gas supplies are turned off at the source and that vent is clear of obstructions.

3)

Confirm that all manual shut-off gas valves between the boiler and gas source are closed.

4)

If not already done, flush the system to remove sediment, flux, and traces of boiler additives.

5) Fill the boiler and hydronic system with water meeting the following requirements below (also see the note on the next

page):

•

pH between 6.5 and 9.5

•

Hardness less than 7 grains/gallon

•

Chlorides less than 200 ppm

•

Pressurize the system to at least 12 psi at the boiler

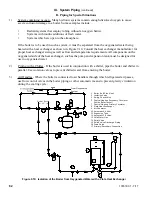

6) Bleed air from the heat exchanger using the manual air vent in the top left side of the heat exchanger (Figure 11.1). To do

this install a piece of ¼” ID clear tubing over the hose barb and route the tubing to a location where water will not dam-

age controls or nearby construction. Turn vent counter clockwise and allow heat exchanger to vent until a steady stream

of water is observed. Close vent and remove hose.

7)

Check all gas piping for leaks and purge piping sections that are filled with air. Refer to the

National Fuel Gas Code

for

additional information on testing and purging gas lines.

8)

Confirm vent system is complete and free of obstructions before attempting to fire boiler.

9) Inspect all wiring for loose, uninsulated or miswired connections.

10) If the boiler is to be converted to propane, convert as described in conversion kit instructions. If boiler is operating at

elevations above 2000ft, see Appendix A of this manual for setup instructions.

XI. Start-Up and Checkout

Warning

Burn Hazard. The maximum operating pressure of this boiler is 30 psig (210 kPa) or 50 psig (340 kPa),

depending on the model and safety relief valve option selected. Never exceed the maximum allowable

working pressure on the heat exchanger ASME plate.

DANGER

Explosion Hazard. Do not use matches, candles, open flames or other ignition source to check for

leaks.

Make sure that the area around the boiler is clear and free from combustible materials, gasoline and

other flammable vapors and liquids.

Warning

Completely read, understand and follow all instructions in this manual before attempting start-up.

nOTiCE

Safe lighting and other performance criteria were met with the gas train assembly provided on the boiler

when the boiler underwent the test specified in ANSI Z21.13.

Summary of Contents for K2WT-080B

Page 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

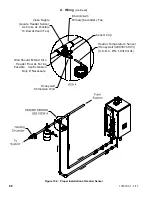

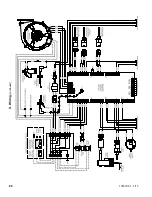

Page 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Page 90: ...90 107672 01 7 17 X Wiring continued...

Page 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

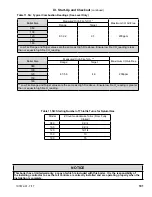

Page 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Page 147: ...147 107672 01 7 17 XV Service Parts continued...

Page 151: ...151 107672 01 7 17 XV Service Parts continued...

Page 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Page 162: ...162 107672 01 7 17...

Page 163: ...163 107672 01 7 17...

Page 164: ...164 107672 01 7 17...

Page 165: ...165 107672 01 7 17...

Page 166: ...166 107672 01 7 17...

Page 167: ...167 107672 01 7 17...