33

VIII. SySTEm START-UP (continued)

cycling the burner operation about 5 to 10 times will

rid oil line of this air.

2. IF NOZZLE CONTINUES TO DRIP, repeat

Paragraph H, Step 1 above. If this does not stop the

dripping, remove cut-off valve and seat, and wipe

both with a clean cloth until clean, then replace and

readjust oil pressure. If dripping or after burn

persist replace fuel pump.

L.

TEST CONTROLS.

1. Check thermostat operation. Raise and lower

thermostat setting as required to start and stop

burner.

WARNING

Before installation of the boiler is considered

complete, the operation of all boiler controls must

be checked, particularly the primary control and

high limit control.

2.

VERIFY OIL PRIMARY CONTROL FEA-

TURES

using procedures outlined in Instructions

furnished with control or instructions as follows:

a.

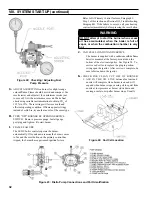

GeniSys 7505 Control Features

, see Figure 25.

i.

The GeniSys 7505 is a microprocessor-based

control. The indicator light provides diagnos-

tic information for lockout, recycling and cad

cell status. There is a manual reset button to

exit the Lockout Mode.

Figure 25: GeniSys 7505 Oil Primary Terminals,

LED's and Reset Button

ii.

Pump Priming Cycle: To facilitate purging

air from the oil lines and filters, the 7505 can

be placed in a purge routine by:

• After the burner starts, press and hold the

reset button for 15 seconds until the

yellow light turns on. This indicates that

the button has been held long enough.

• Release the reset button. The yellow light

will turn off and the burner will start up

again.

• At burner start up, click the reset button

while the igniter is till on. This will

transition the control to a dedicated

Pump Prime mode, during which the

motor, igniter, and valve are powered for

four (4) minutes. The yellow light will be

on.

• At the end of four (4) minutes, the yellow

light will turn off and the control will

automatically return to standby mode.

iii.

Limited Recycle:

This feature limits the

number of recycle trials (for each call for

heat) to a maximum of three trials. If the

flame is lost three times and does not success

-

fully satisfy a call for heat, the 7505 locks

out.

iv.

Limited Reset (Restricted Mode):

In order to

limit the accumulation of unburned oil in the

combustion area, the control can only be reset

three times. The reset count returns to zero

each time a call for heat is successfully

completed.

v.

T-T Jumper: Select models have pre-installed

T-T jumper.

DO NOT

remove jumper.

Note:

DO NOT

remove "T-T" jumper

unless

wiring diagram indicates a direct connec-

tion from thermostat and/or tankless

heater aquastat control to the oil burner

primary control's "T-T" terminal. Refer to

appropriate wiring diagram, see Figure

11A or 11B.

vi.

Diagnostic LED: The indicator light on oil

primary control provides lockout, recycle and

cad cell indications as follows:

•

Flashing at 1 Hz (½ second on, ½ second

off): system is locked out or in Restricted

Mode.

•

Flashing at ¼ Hz (2 seconds on, 2 seconds

off): control is in Recycle Mode.

•

On: cad cell is sensing flame.

•

Off: cad cell is not sensing flame.

Summary of Contents for LE DV Series

Page 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Page 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Page 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Page 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

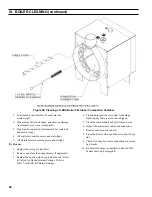

Page 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

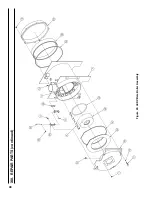

Page 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Page 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Page 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...