62

xIII. TROUBLE SHOOTING (continued)

Possible

ERR

(Boiler Control Error) Values:

Err

Value Description

1

Temperature Sensor Fault

2

Communications Fault

3

Internal Hardware Fault

4

Burner Output (B1) Fault

5

Line Voltage Fault (< 80 Vac)

6

Fuse Missing

7

User Setting Lost, (reset to factory defaults)

8

Manual Reset Lockout (resettable)

Possible

STA

(status) Values:

sTa

Value Description

1

Standby

4

Pre-purge

6

Trial for Ignition

7

Carryover

8

Running

9

Post-Purge

10

Retry/Recycle Display

14

Hard Lockout

15

Waiting for Limit to Close

16

Flame Present Out of Sequence

17

Self Test

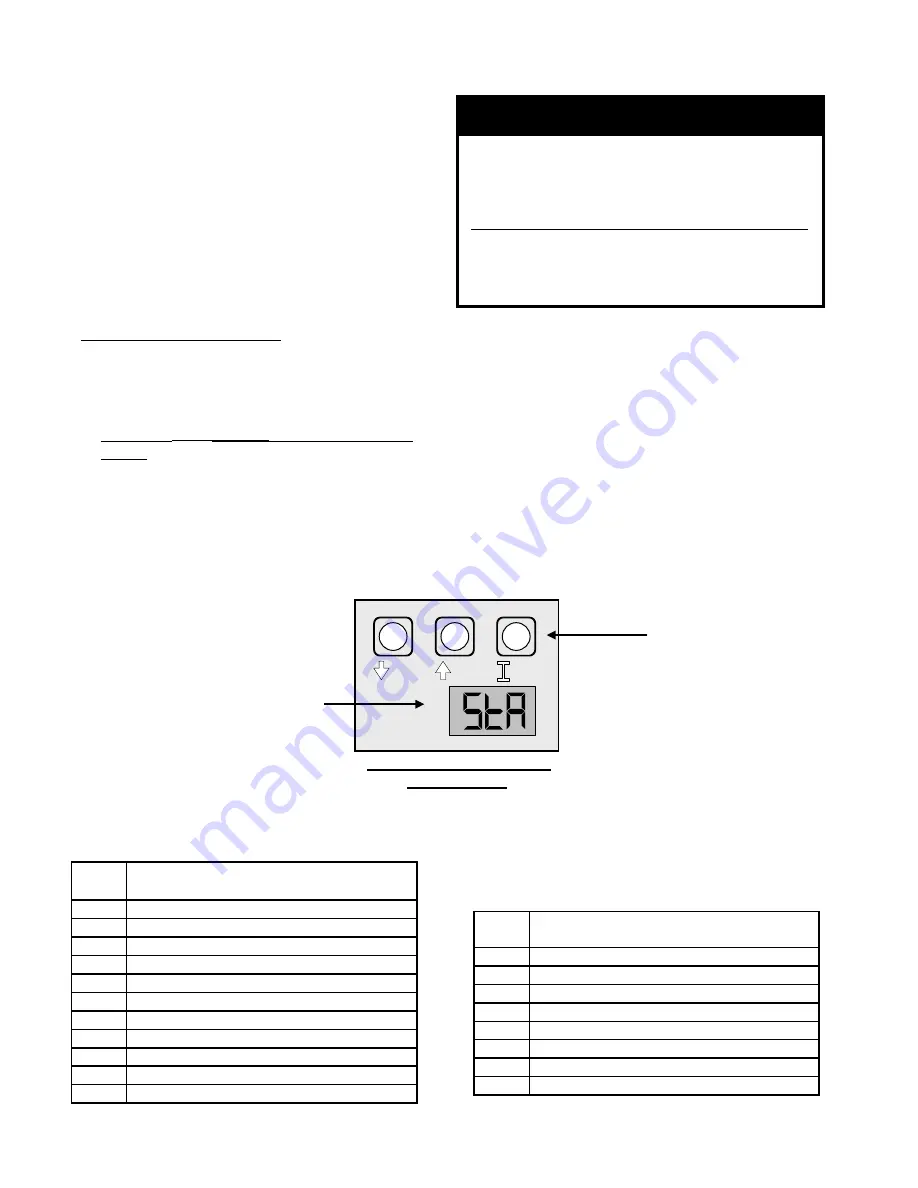

StA

Status (see Status Numbers)

bt

Boiler Temperature

SP

Operating Setpoint (Outdoor Reset)

HL

High Limit Setpoint

HdF

High Limit Differential

hr

Heat Request Status

dh

DHW Heat Request Status

CAD

Cad Cell Resistance (ohms)

run

Run Time Hours

CYC

Boiler Cycles

Err

Error (see Error Numbers)

Erp

External Device Error (see Error Numbers)

Operating Mode Parameters

Press “I” key on the control to

change from one parameter to the

next. Each setting will alternate

between display code (for

example

STA

) and value.

Figure 36: Boiler Control

User Interface

3. Control locks out after Trial For Ignition (TFI).

a. No oil to burner.

b. Shorted electrodes.

c. Nozzle clogged.

d. Airflow too high.

e. Ignitor module defective.

f. CAD cell defective.

g. Oil valve stuck open or closed.

Note: The Safety Monitoring Circuit (SMC) is

designed to provide lockout in the event of a

stuck or welded motor relay.

C. IQ OIL BOILER CONTROL

When a problem occurs with the boiler operation, the IQ

Control System easily provides specific, valuable information

to help resolve the issue quickly. The display on the Boiler

Control should be the first place to check, see Figure 36.

1. Error Code

"Err"

IS NOT

displayed on the Boiler

Control: This is one of two conditions that occur when

a problem arises. In this circumstance, the following

table can be used to determine the problem and

possible causes.

NOTICE

If flame is not established within 15 seconds of

oil valve actuation (known as Trial For Ignition

[TFI]) lockout will occur. Lockout is indicated

by a red LED solid-on located on the oil primary

control.

Hard Lockout will occur if the Oil Primary

Control locks-out three (3) times during a call

for heat. This is indicated by red light reset

button solid-on.

D.

BEFORE TROUBLESHOOTING

The following pages contain trouble shooting tables for

use in diagnosing control problems. When using these

tables the following should be kept in mind:

1. This information is only meant to be used by a

professional heating technician as an aid in diagnosing

boiler problems.

2. Where applicable, follow all precautions outlined in

Section IX, System Start-Up .

3. In general, these tables assume that there are no loose

or miswired electrical connections. Before using these

tables inspect all electrical connections on the boiler to