33

A.

General Guidelines

1. Read and follow all venting, combustion air,

water piping, gas piping and electrical instructions

contained in this manual unless otherwise instructed

in this section.

2. Consult Local Building Codes or National Fuel Gas

Code, NFPA 54/ANSI Z222.3 for restrictions and

instructions on modular boiler installations.

B.

Module Sizing

U.S. Boiler recommends sizing each boiler in a modular

system to provide 20 % of the combined heating load

where ever possible.

C.

Venting

1. Each boiler must have an individual vent pipe.

Refer to Venting Section of this manual for venting

guidelines and options.

WARNING

Do not manifold vent pipes together.

2. The maximum vent length for each boiler is fifty

(50) equivalent feet.

3. The minimum horizontal distance between vent

terminations is one (1) foot. Additional horizontal

distance is desirable to avoid frost damage to the

building. Vent terminations must be at least twelve

(12) inches above the ground plus the expected

snow accumulation.

CAUTION

Installing multiple vent terminations close

together promotes frost buildup on buildings.

To minimize this possibility, extend the distance

from the building to the end of the vent

termination and increase the horizontal distance

between terminations.

4. Multiple vertical vent pipes may be piped through

a common conduit or chase so that one roof

penetration may be made. Each vent termination

must be one (1) foot from other terminations.

D.

Water Piping

(See Table 9 and Figure 21)

Installing a low water cutoff in the system piping of

modular systems is strongly recommended and may be

required by Local Codes.

E.

Gas Piping

1. Refer to National Fuel Gas Code, Local Codes and

Tables 7 and 8 for gas pipe sizing.

VII. MODULAR INSTALLATION

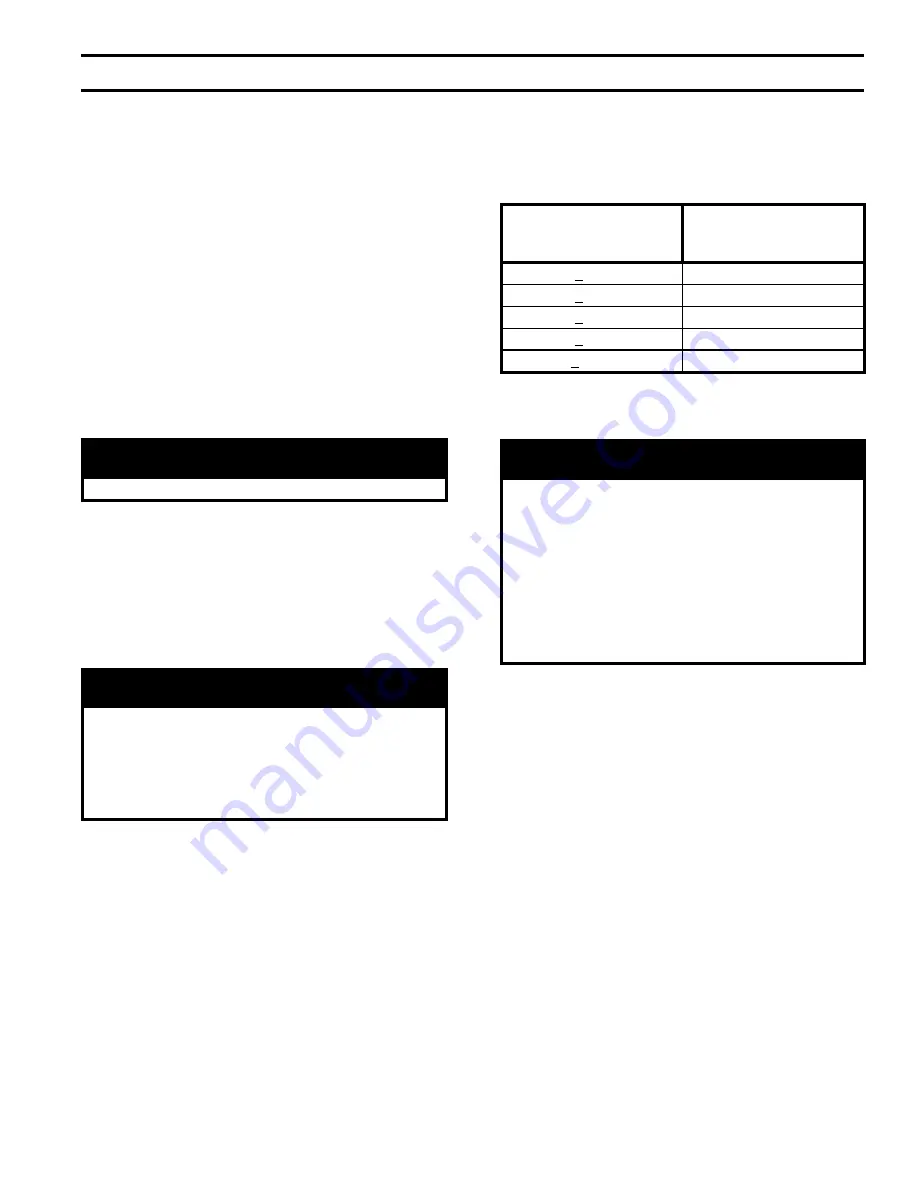

Table 9: Modular Boiler Water Manifold Sizing

2. Each boiler must be piped as shown in Figure 16.

WARNING

If gas pressure in the building is above ½ psig,

an additional gas pressure regulator is required.

Using one additional regulator for multiple

boilers may result in unsafe boiler operation.

The additional regulator must be able to properly

regulate gas pressure at the input of the smallest

boiler. If the regulator cannot do this, two or

more additional regulators are required. Consult

regulator manufacturer and/or local gas supplier

for instructions and equipment ratings.

F.

Electrical

1. Each boiler must be provided with a fused

disconnect and service switch.

2. Install wiring in accordance with requirements of

authority having jurisdiction. In the absence of such

requirements, follow the National Electric Code,

NFPA 70 and/or CSA C22.1 Electric Code.

G.

Modular Boiler Control Systems

Contact a controls manufacturer such as Honeywell or

Tekmar to properly apply a modular control system.

Common systems may use outdoor temperature, return

water temperature or both to stage the boilers.

Combined Output

(MBH)

Recommended Minimum

Common Water Manifold

Size (NPT)

< 166

1¼”

< 260

1½”

< 550

2”

< 900

2½”

< 2000

3”

Summary of Contents for PVG3

Page 14: ...14 Figure 4 Horizontal Vent Installation III Venting continued...

Page 16: ...16 Figure 7 Attic Offset Figure 6 Vertical Vent Installation III Venting continued...

Page 29: ...29 Figure 17 Wiring Connection Diagram VI Electrical continued...

Page 31: ...31 Figure 19 Circulator Zoned System Wiring Diagram VI Electrical continued...

Page 32: ...32 Figure 20 Zone Valve Zoned System Wiring Schematic VI Electrical continued...

Page 34: ...34 Figure 21 Modular Boiler Piping VII Modular Installation continued...

Page 36: ...36 Figure 22 Operating Instructions VIII System Start up continued...

Page 51: ...51 Figure 29 Flue and Burner Cleanout 1 Burner XI Service continued...

Page 54: ...54 XII Repair Parts continued...

Page 56: ...56 XII Repair Parts continued...

Page 60: ...60 XII Repair Parts continued...

Page 67: ...67 SERVICE RECORD DATE SERVICE PERFORMED...

Page 68: ...68 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...