106636-04 - 8/22

6

X-2

Installation, Operating & Service Manual

4

Locating Boiler

Code Requirements

2. All wiring must comply with

National Electrical

Code

ANSI/NFPA 70.

3. Where required by authority having

jurisdiction, installation must conform to

Standard for Controls and Safety Devices for

Automatically Fired Boilers

, ANSI/ASME CSD-1.

Location Considerations

1. Provide combustion and ventilation air in

accordance with section "

Air for Combustion and

Ventilation

," of

National Fuel Gas Code

, ANSI

Z223.1/NFPA 54, or applicable provisions of local

building codes.

2. If replacing an existing boiler, check for and

correct common system problems including:

A. System leaks resulting in premature heat

exchanger failure from oxygen corrosion or

hardness deposits.

B. Inadequate freeze protection resulting in

system freezing and leaking.

C. Dirt or debris left in existing piping if it has not

been properly flushed or cleaned.

3. Appliance is listed for installation on combustible

flooring and must not be installed on carpeting.

4. Install on level floor. For basement installation

provide concrete base if floor is not level or if

water may be encountered on floor around boiler.

5. Protect gas ignition system components from

water (dripping, spraying, etc.) during appliance

operation and service.

6. Locate boiler to avoid water damage in case

there is a leak. If boiler must be located in an

area sensitive to water damage, install drain

pan underneath boiler and pipe to a suitable

drain location. Manufacturer will not be held

responsible for water damage resulting from

this appliance or any of its components.

7. Check for and remove any combustible

materials, gasoline, or other flammable liquids

from area around boiler.

8. Check for and remove any potential combustion

air contaminants from area around boiler. See

Table 4-1.

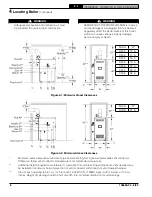

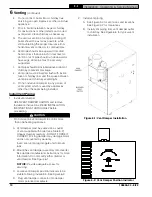

Clearances

1. Provide clearances between boiler jacket and

combustible material in accordance with

authority having jurisdiction. Minimum

clearances to combustible material shown in

Figure 4-1 and 4-2.

2.

Recommend 24 in. service clearance from left

side, right side and front.

NOTICE:

If recommended service clearances

are not provided, it may be necessary to remove

boiler for service.

3. Boiler must not be installed on carpeting.

1. Installations must conform to requirements of

authority having jurisdiction or, in the

absence of such requirements, to

National Fuel

Gas Code

, ANSI Z223.1/NFPA 54.

Table 4-1: Corrosive Combustion Contaminants

and Sources

Contaminants to avoid:

Spray cans containing chloro/fluorocarbons (CFC’s)

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms.

Adhesives used to fasten building products and

other similar products

Excessive dust and dirt

Areas likely to have contaminants:

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

NOTICE:

Flue side corrosion caused by

contaminants is not covered by warranty.