106636-04 - 8/22

21

X-2

Installation, Operating & Service Manual

10

System Start-up and Checkout

1. Visual Main Burner Check.

Inspect burners for dislodgement during

shipment. Rear of burners should be in vertical

slots in rear of burner tray and front of burners

should be seated completely on orifices.

2. Fill Boiler with Water.

Refer to Appendix B for

important information on water quality and boiler

additives.

3. Purge Air from System.

A. Fill entire heating system with water and

vent air from boiler, radiators and system,

one zone at a time.

B. Isolate boiler by closing isolation valves. For

primary - secondary systems, close additional

isolation valve to ensure water flows through

zones.

C. Isolate all circuits by closing zone valves

or turning off zone circulators.

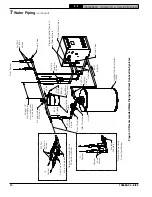

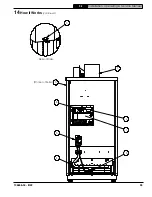

D. Attach hose to drain valve located

on return piping (see Figure 7-2 and 7-3).

Note-Terminate hose in five gallon bucket,

at a suitable floor drain, or outdoor area).

E. Starting with one circuit, open zone valve or

start circulator.

F. Open drain valve.

G. Open fill valve.

H. Allow water to flow through system until

discharge from hose is bubble free for 30

seconds.

I. Open zone valve or start circulator to second

zone to be purged, then close first.

Repeat this step until all zones have

been purged, but always have one zone

open. At completion, open all zone valves or

start all circulators.

J. Close hose bib, open boiler isolation

valve, continue filling system until

pressure gauge reads 12 psi.

Close fill valve. (Note - If make-up water

line is equipped with pressure reducing

valve, system will automatically fill to 12

psi).

K. Remove hose from drain valve.

DANGER

Explosion Hazard.

Do not use matches, candles, open flames, or

other ignition sources to check for leaks. Failure

to comply could result in severe personal injury,

death, or substantial property damage.

!

WARNING

• Make sure that the area around the boiler is clear

and free from combustible materials, gasoline,

and other flammable vapors and liquids.

• Damper must be in open position when

appliance main burner is operating.

!

4. Perform gas leak test upstream of boiler shutoff

valve.

A. Protect boiler gas valve.

i. For all testing over ½ psig, boiler

and manual shutoff valve must be

disconnected from gas supply piping.

ii. For testing at ½ psig or less, isolate

boiler from gas supply piping by closing

boiler manual shutoff valve.

B. Locate leaks using listed combustible

gas detector, a noncorrosive leak detection

fluid or other listed leak detection method.

C. Tighten appropriate pipe connections.

5. Perform limit check.

A. Ensure gas to boiler is off.

B. Set ROOM THERMOSTAT to lowest setting.

C. If limits are functioning properly (LWCO,

Auxiliary limit, flame rollout switch, blocked

vent switch, damper), boiler should spark.

If boiler does not spark, see Section 14

"Troubleshooting" for guidance.

D. Turn "OFF" the electric switch to boiler.

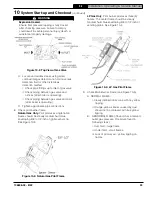

6. Start boiler according to "Operating Instructions"

in Figure 10-1.

7. Perform gas leak test downstream of boiler

manual shutoff valve.

A. Open manual shutoff valve.

B. PURGE AIR FROM GAS PIPING by loosening

(or removing) “Inlet Pressure Tap” plug on gas

valve (See Figure 10-2). Tighten (or replace)

plug when you start to smell gas. Adequate

ventilation must be provided and no smoking

or open flame permitted.