SKU 66786

for technical questions, please call 1-800-444-3353.

Page 10

To PREVEnT ExPloSion:

lubricate tool only with

specified lubricants.

lubricate air inlet using only

pneumatic tool oil. lubricate

internal mechanism using

only white lithium grease.

other lubricants may damage

mechanism and may be

highly flammable, causing an

explosion.

cleaning, maintenance, and

lubrication

note:

These procedures are in addition to

the regular checks and maintenance

explained as part of the regular op-

eration of the air-operated tool.

once a year after discharging con-

1.

tents of the Tank, remove the drain

Plug (24) to drain accumulated

sludge. To reattach the Plug, wrap

three turns of thread sealing tape

(not included) on the Plug thread

and secure in place. do not over-

tighten.

Keep the outside of the Tank free of

2.

oil or grease. Use only a mild soap

and damp cloth when cleaning. Do

not use flammable or combustible

solvents.

Before and during each use, inspect

3.

the Hose (13) for damage. Do not

allowed the used oil to surpass the

Tank’s 20-gallon capacity.

After use, store in a dry, secure area

4.

out of reach of children.

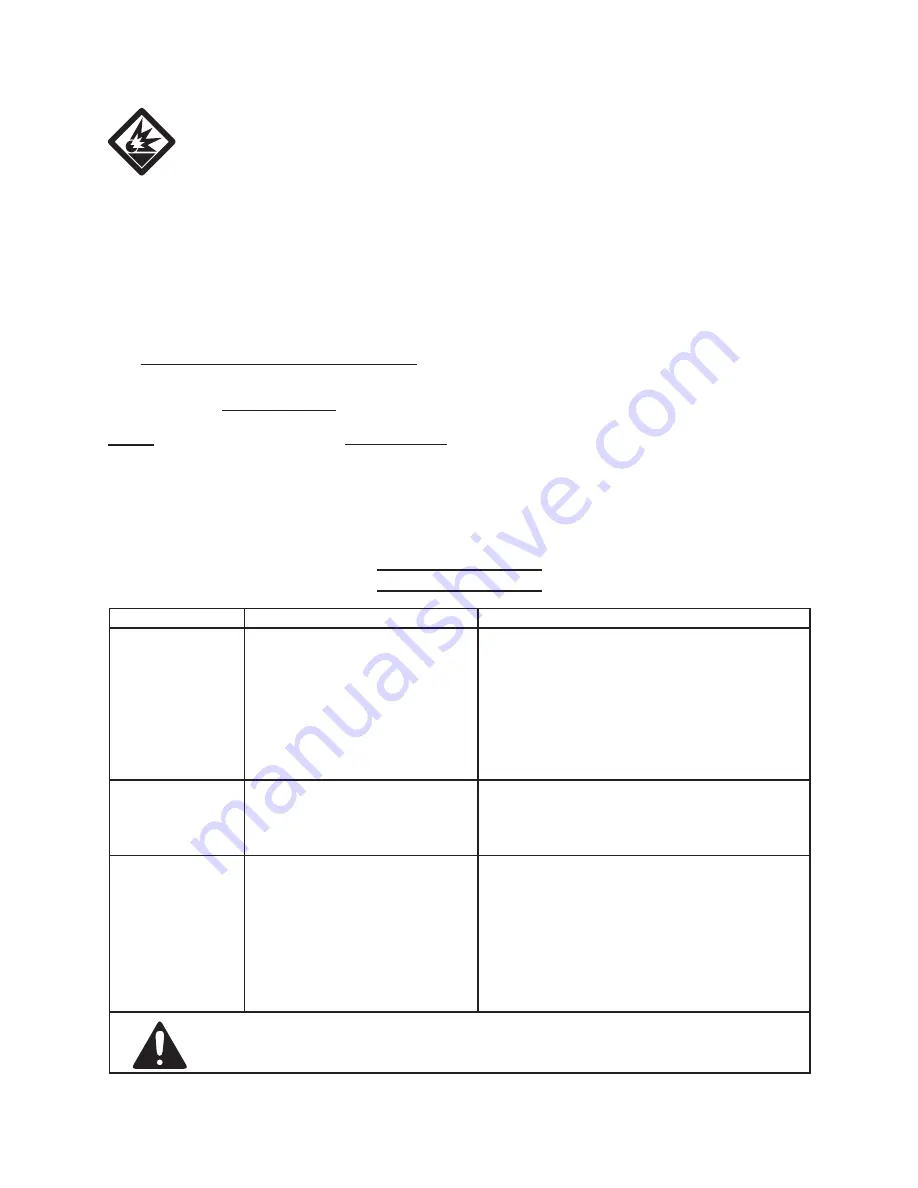

Troubleshooting

Problem

Possible causes

likely Solutions

Decreased output.

Not enough air pressure and/

1.

or air flow.

Blockage of hose.

2.

Accumulated sludge.

3.

Check for loose connections and make sure

1.

that air supply is providing enough air flow

(CFM) at required pressure (PSI) to the

tool’s air inlet.

do not exceed maximum air

pressure.

Gently blow air from Nozzle into Tube.

2.

After draining the oil, remove Plug and

3.

evacuated sludge.

Housing heats

during use.

Incorrect lubrication or not

1.

enough lubrication.

Worn parts.

2.

Lubricate using air tool oil and grease

1.

according to directions.

Have qualified technician inspect internal

2.

mechanism and replace parts as needed.

Severe air

leakage.

(Slight air leakage

is normal,

especially on older

tools.)

Cross-threaded housing

1.

components.

Loose housing.

2.

Damaged valve or housing.

3.

Dirty, worn or damaged valve.

4.

Check for incorrect alignment and uneven

1.

gaps. If cross-threaded, disassemble and

replace damaged parts before use.

Tighten housing assembly. If housing cannot

2.

tighten properly, internal parts may be

misaligned.

Replace damaged components.

3.

Clean or replace valve assembly.

4.

follow all safety precautions whenever diagnosing or servicing the

tool. disconnect air supply before service.