SKU 66786

for technical questions, please call 1-800-444-3353.

Page 6

funcTional dEScRiPTion

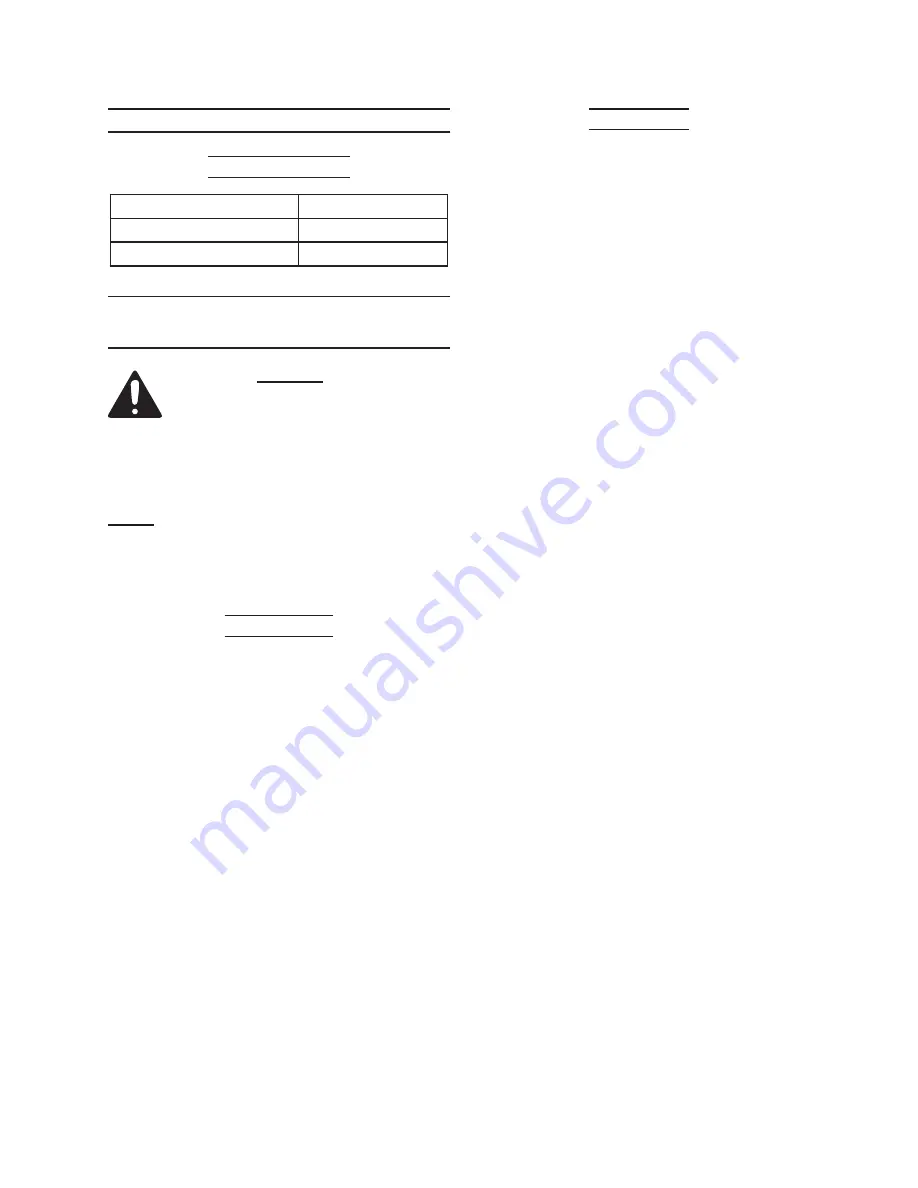

Specifications

Capacity

20 Gallons

Operating Air Pressure

10 PSI

Air Inlet

1/4” -18 NPT

iniTial Tool SET uP/

aSSEmBlY

Read the EnTiRE imPoRTanT

SafETY infoRmaTion

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

note:

For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

unpacking

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon

as possible.

This air tool may be shipped with a

•

protective plug covering the air inlet.

Remove this plug before set up.

assembly

Be sure to assemble Oil Lift Drain

1.

on flat, level surface able to support

weight of tool.

To begin assembly, slide one Fixed

2.

Wheel (18) onto each end of the axle

of the Tank (23). Lock Wheels into

place using Washers (17) and Retain-

ing Rings (16). See

assembly dia-

gram

on page 12.

If the Casters are not already at-

3.

tached to the Tank, fasten one Swivel

Caster (22) to each plate located

on the base of the Oil Lift. Slide on

Spring Washer (20), Washer (21),

and then thread Locking Nut (19)

onto Caster stem to secure Swivel

Casters in place. See

assembly

diagram

on page 12.

Insert the Handle (10) into the slot on

4.

the upper side of the Tank (23). Fas-

ten in place using the Bolts (11). See

assembly diagram

on page 12.

Insert the Bushing (4) into the Nut (5)

5.

and thread the Nut into the Ball Valve

until secure.

When tightening, make sure the Lock

6.

Knob (3) is parallel with the handle of

the Gate Valve (6).

Thread the Bowl (1) into the Drain

7.

Tube (2) until fastened securely.

Insert the Drain Tube, with the Bowl

8.

fastened to the other end, into the

Bushing. Select the required height

and lock Drain Tube in place using

the Locking Knob (3). See

assem-

bly diagram

on page 12.