PRODUCT SPECIFICATIONS

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram.

Keep your invoice with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for future reference.

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may

result in serious injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1.

Keep your work area clean and well lit. Cluttered benches and dark areas

invite accidents.

SKU 92252 For technical questions, please call 1-800-444-3353 PAGE 2

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List on page 9 are

included. If any parts are missing or broken, please call Harbor Freight Tools at the

number shown on the cover of this manual as soon as possible.

GENERAL SAFETY RULES

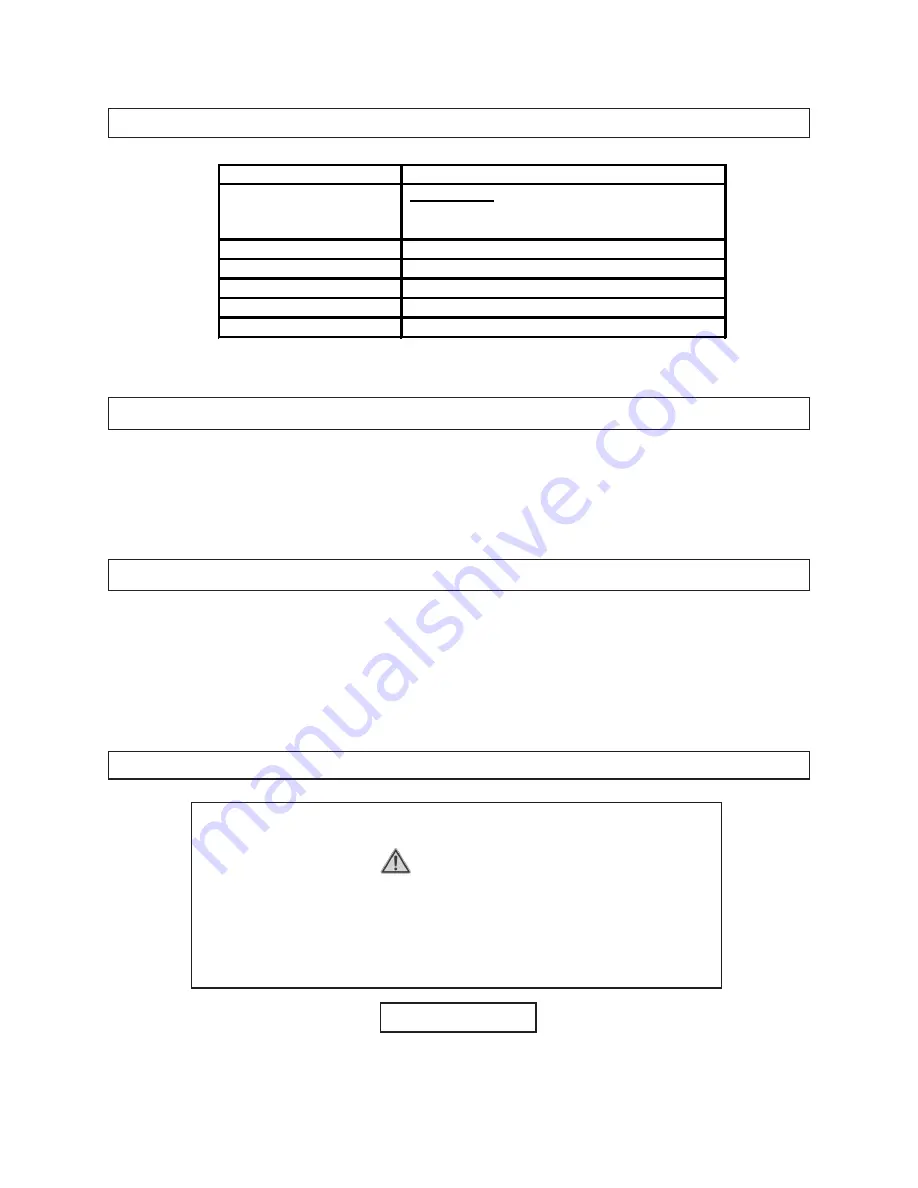

Item

Description

Capacity

Will accept :

Standard 14 ounce grease cartridge

or 24 ounces bulk loaded.

Function Method

Piston and Lever (Manual).

Extension Pipe Size

6” Long.

Coupler Type

4 Jaw.

Additional Features

Air Release Valve / Bulk Loader Fitting.

Weight

3.95 Pounds.