SKU 93874

For technical questions, please call 1-800-444-3353.

Page 11

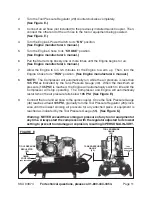

QUICK

COUPLER

(NOT INCLUDED)

TOOL PRESSURE

REGULATOR

(29)

TOOL PRESSURE

GAUGE

(55)

TANK PRESSURE

GAUGE

(46)

FIGURE E

TOOL

PRESSURE

REGULATOR

(29

2.

Turn the Tool Pressure Regulator (29) counterclockwise completely.

(See Figure E.)

3.

Connect an air hose (not included) to the previously installed Quick Coupler. Then,

connect the other end of the air hose to the tool or equipment being powered.

(See Figure E.)

4.

Turn the Engine’s Power Switch to its

“ON”

position.

(See Engine manufacturer’s manual.)

5.

Turn the Engine Choke to its

“CHOKE”

position.

(See Engine manufacturer’s manual.)

6.

Pull the Starter Grip briskly one or more times until the Engine begins to run.

(See Engine manufacturer’s manual.)

7.

Allow the Engine to run 3-5 minutes for the Engine to warm up. Then, turn the

Engine Choke to its

“RUN”

position.

(See Engine manufacturer’s manual.)

8.

NOTE:

The Compressor will automatically run while the air pressure is less than

145 PSI

as indicated by the Tank Pressure Gauge (46). When the maximum air

pressure (

145 PSI

) is reached, the Engine will automatically switch to idle and the

Compressor will stop operating. The Compressor and Engine will automatically

restart when the air pressure falls below

105 PSI

.

(See Figure E.)

9.

Connect the tool and air hose to the quick coupler. Once the Tank Pressure Gauge

(46) reaches

at least

105 PSI

, gradually turn the Tool Pressure Regulator (29) clock-

wise until the lowest working air pressure for any attached piece of equipment is

reached as indicated by the Tool Pressure Gauge (55).

(See Figure E.)

Warning: NEVER exceed the working air pressure of any tool or equipment at

any time. Always start the compressor with the regulator adjusted to its lowest

setting to prevent tool damage or explosion, resulting in PERSONAL INJURY.