SKU 93874

For technical questions, please call 1-800-444-3353.

Page 13

INSPECTION, MAINTENANCE, AND CLEANING

1.

WARNING!

Make sure the Power Switch of the Engine is in its

“OFF”

position. Release all air pressure from the system and disconnect all tools and

equipment from the Air Compressor before performing any inspection, mainte-

nance, or cleaning procedures.

2.

Before each use,

inspect the general condition of the Air Compressor. Check

for loose screws, misalignment or binding of moving parts, cracked or broken

parts, damaged electrical wiring, loose air fittings, and any other condition that

may affect the safe operation of the Compressor. If abnormal noise or vibration

occurs, have the problem corrected before further use.

Do not use damaged equipment.

3.

Before each use,

check the Engine oil level. If necessary, fill the crankcase of

the Engine with the proper amount and type of engine oil.

Refer to the Engine

manufacturer’s manual for all inspection, maintenance, and cleaning in-

structions.

4.

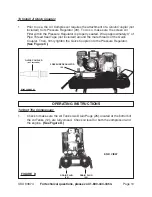

Before each use,

check the Air Compressor oil level. If necessary, fill with a

premium quality, 30-weight, non-detergent, compressor oil.

(See Figure B.)

5.

Daily:

Empty condensation from the Air Compressor’s Tanks (12). The Tanks

should be emptied daily to release all trapped moisture that may cause Air Tank

corrosion. Allow sufficient time for all of the condensation to escape from the

Tanks. Then, firmly retighten the two Drain Plugs (25).

(See Figure D.)

6.

Every 500 hours or 12 months,

replace the old compressor oil with new, pre-

mium quality, 30-weight, non-detergent, compressor oil. To do so, remove the

Screw (36A) located at the base of the Air Compressor. Drain the old oil into a

proper container. Then, refill the Air Compressor with new oil.

(See Figure B.)

7.

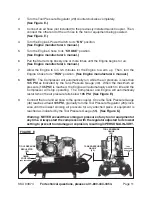

To replace the V-Belt:

Unscrew and remove the six Screws (21) that hold the

front Belt Guard (13) section to the rear Belt Guard section. Then, remove the

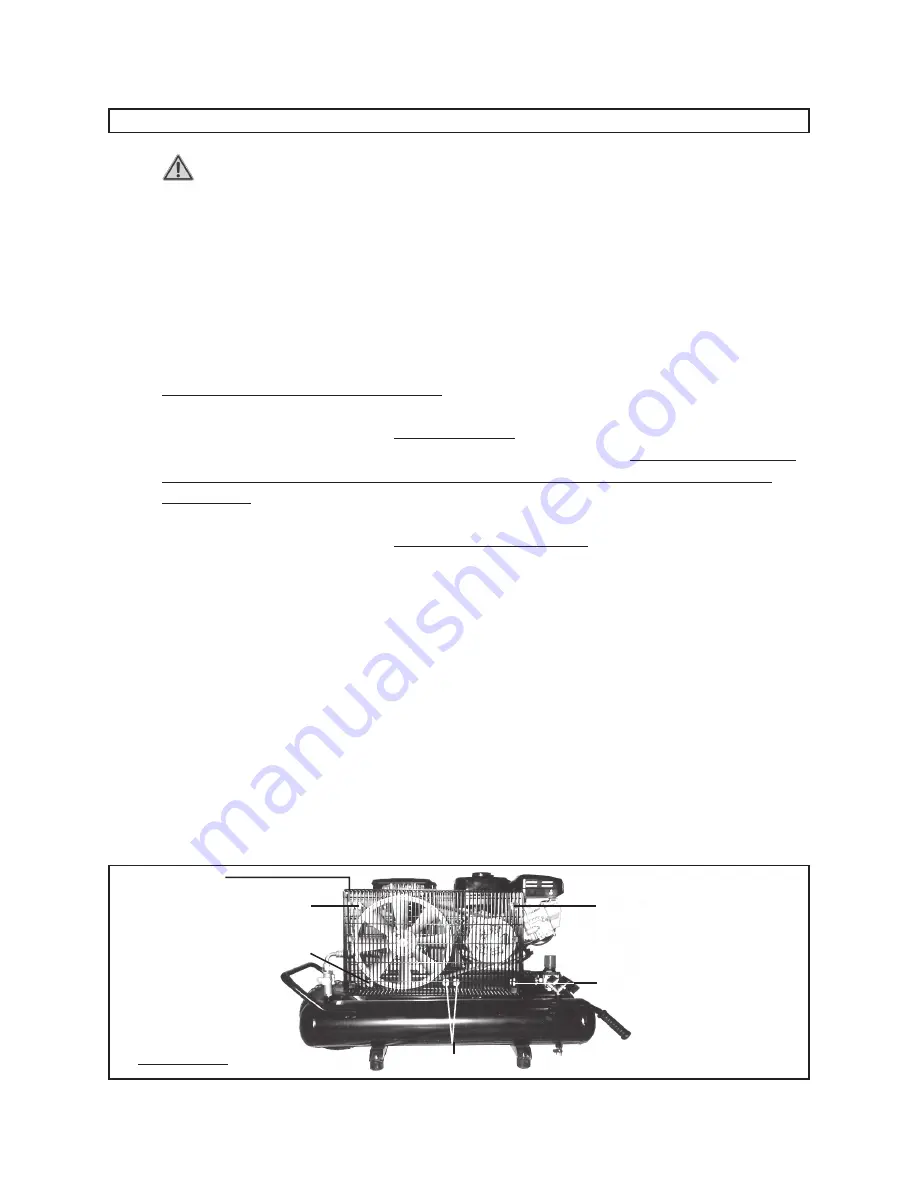

FIGURE G

SCREW (21)

BELT GUARD (13)

SCREW (21)

SCREW (21)

SCREW (21)

SCREW (21)