1/2012

A - 3

56041832 - FLOODKING

ENGLISH - A

INSTRUCTIONS FOR USE

INSPECTION:

Carefully unpack and inspect your FLOOD KING for shipping damage. Each machine is tested and inspected before shipping. Any damage

incurred during shipping is the responsibility of the carrier. You should notify the carrier immediately if you notice damage to the box or to the

machine or parts.

MAINTENANCE:

Prior to each job, inspect the recovery tank pre-fi lters, the stainless steel in-line fi lters, the fl oat, and the drain hose to make sure everything is

clean and able to function properly. After each job, remove and clean both the nylon mesh pre-strainer at the vacuum inlet and the stainless steel

fi lters in the bottom of the recovery tank. Unscrew the clear caps off the in-line fi lters (located under the recovery tank) and clean the screens

often. Pump damage may occur if the fi lters become clogged. Check hose clamps regularly to make sure they are tight. The pump discharges

water at high pressure. If a hose clamp becomes loose, the hose could also come loose, or fall off of the hose barb, and leak water into the base

compartment.

Lubricate the wheels, castors, latches, and quick disconnects with an all purpose silicone spray. The vacuums and the pumps do not require

any scheduled maintenance; however the vacuum motors may require new brushes after 1000 - 1500 hours. Clean the body with an all purpose

detergent, and protect it with an automobile interior spray protectant.

Record the serial number and model of your new fl ood extractor here:

Serial Number: __________________ Model: ________________

Purchase Date:_____________

Write the name and phone number of your distributor:

____________________________________________________________________

____________________________________________________________________

Be sure to register your purchase to activate your warranty

120VAC GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should electrically malfunction, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER!

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualifi ed electrician or

service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the appliance. If

it will not fi t the outlet, have a proper outlet installed by a qualifi ed electrician.

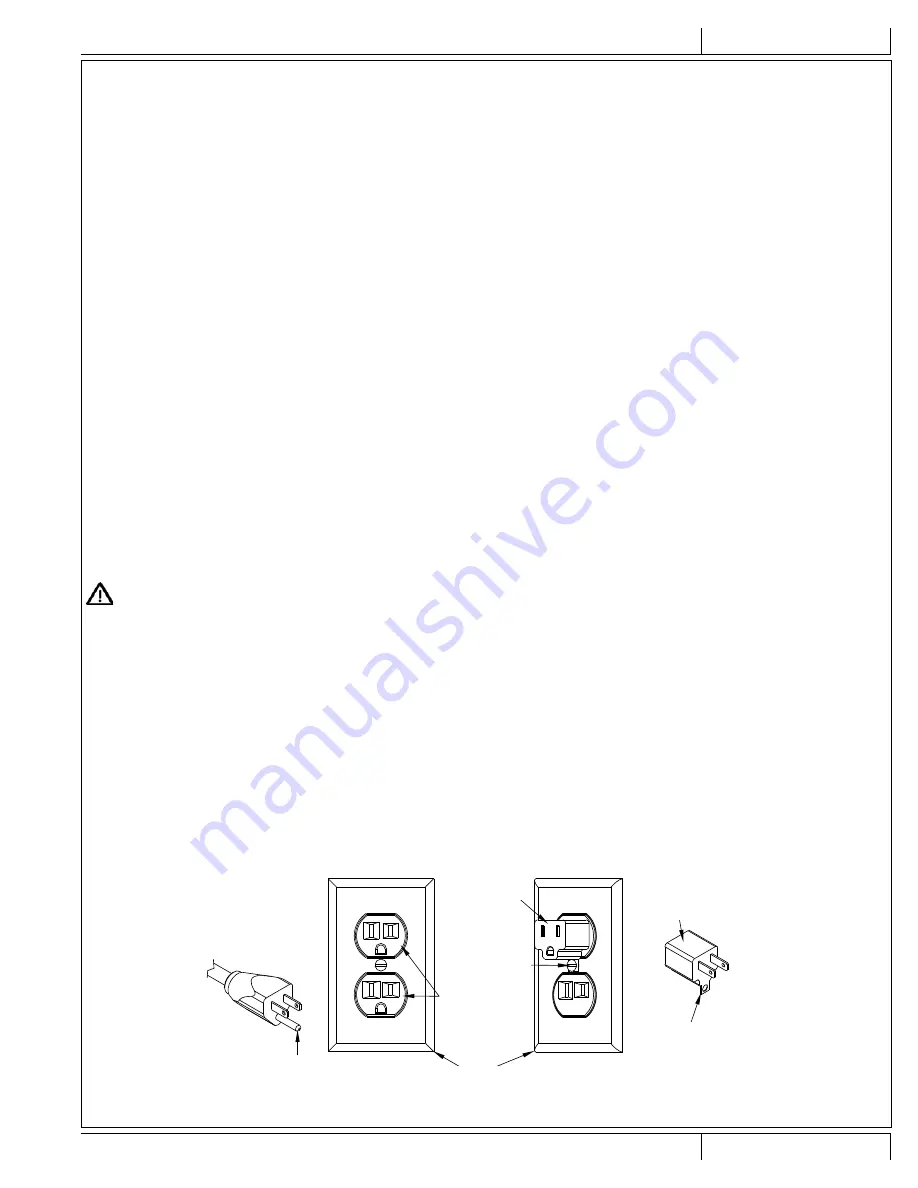

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug that looks like the plug illustrated in Figure 1 below. A temporary

adapter illustrated in Figures 2 and 3 may be used to connect this plug to a 2-pole receptacle as shown in Figure 2 if a properly grounded outlet is

not available. The temporary adapter should be used only until a properly grounded outlet (Figure 1) can be installed by a qualifi ed electrician. The

green-colored rigid ear, tab, or the like extending from the adapter must be connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or Green/Yellow) wire in the cord is the grounding wire. When replacing a plug, this wire must be attached to the grounding pin only.

Extension cords connected to this machine should be 12 gauge, three-wire cords with three-prong plugs and outlets. DO NOT use extension cords

more than 50 feet (15 m) long.

PLEASE NOTE: FOR NORTH AMERICA ONLY

revised 3/2014

Grounding Pin

Tab for Grounding Screw

Adapter

Adapter

Metal Screw

FIGURE 1

FIGURE 2

FIGURE 3

Grounded Outlet Box

Grounded Outlet