ENGLISH / A-19

FORM NO. 56041707 - Agitator

™

16 / 18 Clean & Restore -

A-19

EN

TROUBLESHOOTING

If the possible causes listed below are not the source of trouble, it is a symptom of something more serious. Contact your U.S. Products Service

Center immediately for service.

TRIPPING THE CIRCUIT BREAKER

The Circuit Breaker

(17)

is located on the Operator’s Handle; it protects the electrical circuit and brush motor from damage due to overload

conditions. If the circuit breaker is tripped try to determine the cause.

Brush Circuit Breaker (5 Amp) Possible cause may be:

1

Debris wrapped around the brush drive (remove debris)

2

Brush setting too low (adjust to proper brush setting)

3

Electrical short circuit (have your U.S. Products Service Center or quali

fi

ed electrician check the machine)

Once the problem has been corrected, push the button in to reset the circuit breaker. If the button does not stay in, wait 5 minutes and try again. If

the circuit breaker trips repeatedly, call your U.S. Products Service Center for service.

POOR WATER PICKUP

Possible causes may be:

1

Recovery Tank Full (empty recovery tank)

2

Open recovery tank drain hose (secure drain hose cap or replace)

3

Recovery hose not connected at vacuum shoe (connect hose to vacuum shoe)

4

Recovery hose is kinked or damaged (replace the hose)

5

Recovery tank cover gasket leak (replace gasket)

6

Debris caught in vacuum shoe or recovery hose (clean vacuum shoe and recovery hose)

INADEQUATE OR NO SOLUTION FLOW

Possible causes may be:

1

Solution tank empty (

fi

ll solution tank)

2

Solution lines or screen clogged (

fl

ush lines and screen)

3

Spray Nozzles Clogged (clean nozzles)

4

Faulty Pump (contact an authorized service person)

5

Variable Flow Control Knob incorrectly set on Clean & Restore model (adjust knob)

INADEQUATE OR NO CHEMICAL INJECTION

Possible causes may be:

1

Chemical tank empty (

fi

ll chemical tank)

2

Chemical tank feed hose restricted or damaged (clean tank & remove hose restriction)

3

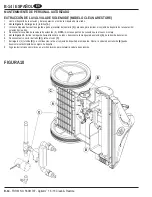

Injector check valve clogged (disassemble and clean)

4

Clogged or incorrect injector meter nozzle (clean & check chemical ratio / install correct nozzle)

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model

Agitator

™

16

Agitator

™

18 Clean & Restore

Model No.

56266115 56266116

Voltage/frequency

V/Hz

120 / 50-60

120 / 50-60

Rated Current

Amp

12.5 12.5

Sound Pressure Level (ISO 11201)

dB (A)/20

μ

Pa

68 68

Total Weight

lbs/kg

170 / 77

217 / 98

Dry Weight

lbs/kg

116 / 52

121 / 55

Vibrations at the Hand Controls (ISO 5349-1)

m/s

2

0.72m/s

2

0.72m/s

2

Solution Tank Capacity

8 gal (30.3

l

)

13 gal (49.2

l

)

L x W x H

inches

44.5 x 19.5 x 37

44.5 x 19.5 x 37

Summary of Contents for AGITATOR 16

Page 56: ......

Page 57: ...Section II Parts Manual 56041707 ...

Page 58: ......

Page 64: ...6 Agitator 16 18 Clean Restore 07 6 FORM NO 56041707 BRUSH ASSEMBLY ...

Page 66: ...8 Agitator 16 18 Clean Restore 07 6 FORM NO 56041707 DECAL SYSTEM ...

Page 77: ......

Page 78: ......

Page 79: ......