FORM NO. 56041891 - 5

SET-UP:

1.

Fill the holding tank with clear water and the detergent of your choice. Mix well. Although this

machine is designed to supply instant hot water, the addition of warm water (not exceeding 54º C/130º

F) to the holding tank will increase the effi ciency of the heater.

2.

Plug in cord #1. Attach the priming hose to the machine (see illustration on previous page). Turn the

pump on and set the switch to the upholstery setting. Run the pump until the pump is fully primed,

then turn off the pump. Remove the priming hose, and attach the cleaning hoses and tool.

3.

Turn on the pump, and spray through the cleaning tool for a few seconds to fi ll the lines with solution.

4.

Plug in cord #2 (identifi ed by a red “H” on the back of the extractor). Wait 2 minutes for the heat

exchanger to reach operating temperature. You may now begin cleaning. It will take about 10 seconds

for the initial heat to reach the wand.

BALL FLOAT VAC SHUTOFF:

When the recovery tank is full, the fl oat system will shut off the incoming air fl ow and prevent water from

entering the vacuum motors. The fl oat may not work properly if the fl oat fi lter is clogged or if there is foam in

the tank.

CAUTION: To avoid vac motor damage, always make sure the fl oat fi lter is clean and the ball

travels freely before turning on the machine, and use a defoamer whenever foam is present.

SPECIFICATIONS:

Rotomolded Body:

Vacuum:

VAC Shutoff:

Pump:

Waterlift:

Heat:

Heater:

Wand:

Weight:

Dimensions:

Lifetime Warranty

One, 3-stage, 7.2”

Ball

fl

oat

Positive displacement, 300 psi carpet, 50 psi upholstery

125”

212º F

1500 Watts

Stainless steel, double bend, twin tip

99 lbs.

26.5H x 18W x 28.75L (inches)

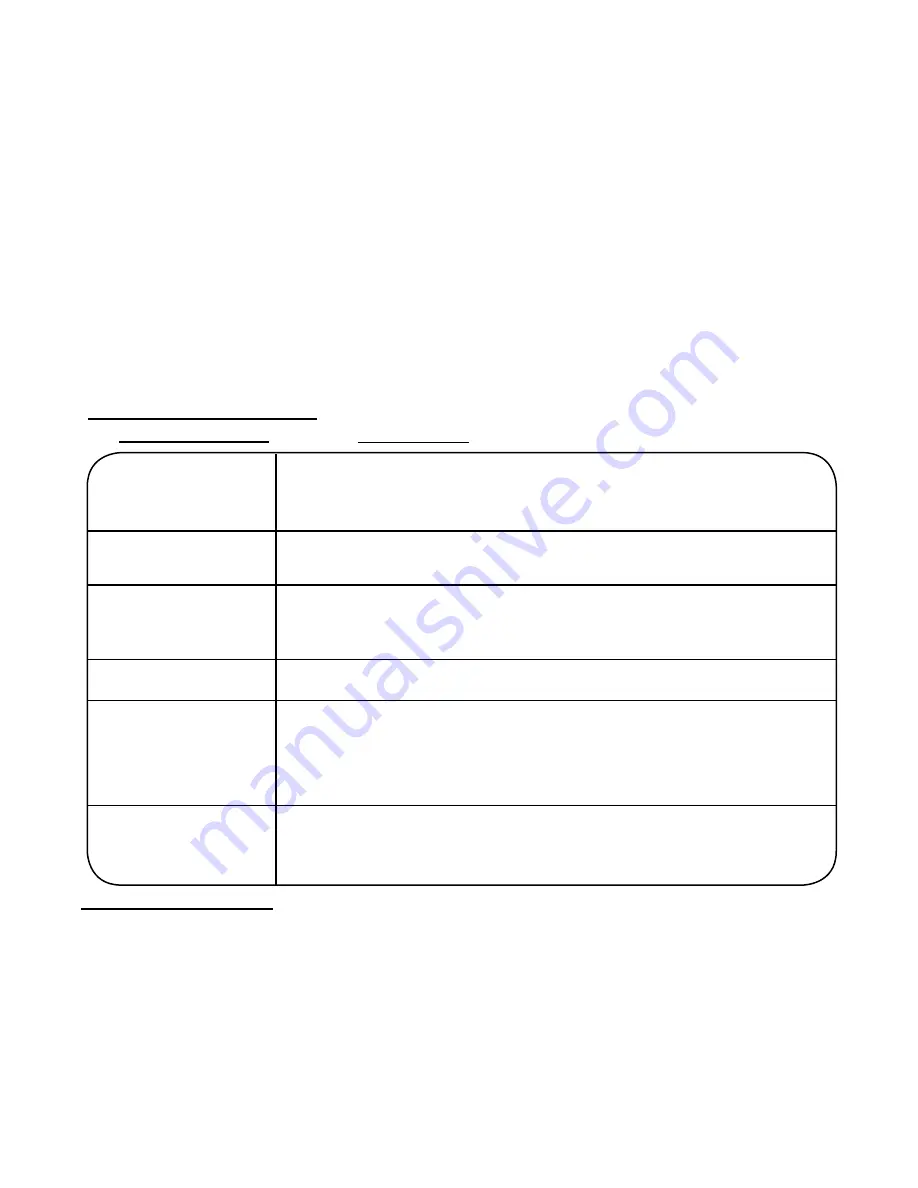

TROUBLE SHOOTING:

IF THIS OCCURS

CHECK THIS

NO SPRAY

PUMP DOEN’T RUN

Solution tank is empty.

Clogged spray tip.

Pump not running.

Valve on wand not operating.

No power to pump. Test the switch.

Test the motor directly to AC power.

Debris plugging cleaning tool or vacuum hose.

Drain gate is not completely closed, or seals are damaged.

Vacuum lid is not closed tight.

No power to motor. Test the switch. Test the vacuum motor.

Spraying too long. Try spraying for 12-15 seconds per cycle. Heat exchanger

needs to be fl ushed.

Wrong tool being used.

Too much water passing through, (longer hose, larger diameter hose, or larger

spray tip), than standard.

No power in the wall outlet - check to see if the breaker has tripped.

Check power cord for ‘opens’.

Call your distributor for additional help.

LOW SUCTION

NO SUCTION

LOW HEAT

NO HEAT

revised 10/10

https://harrissupplyind.com - To Order Parts Call 608-268-8080