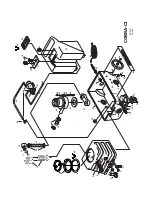

COBRA-C1

PART LIST 120V

ITEM PART

DESCRIPTION

1

903

Drain gate

2

21C

Screw, 8-32 X 5/8"

3

908

Latch

4

187

O-Ring

4A

187B

Washer, rubber

4B

185

Nut, Aluminum, 1-1/2"

5

VT-2

Vacuum Tank, White

6

907

Hose Barb, 1-1/2"

7

921

Elbow, PVC

8

1074

Gasket, Lid, vacuum

9

2086A

Lid, clear, 6", with ring

10

FP193

Manifold, with Ball/Cage

11

185

Nut, Aluminum, 1-1/2"

12

187

O-Ring

13

922

Elbow, PVC

14

156

Hose Clamp

15

430B

Hose, 2" X 21"

15A

430

Hose, 2" X 3”

17

76

Hose Clamp

20

91

Elbow

22

FP228B

Gasket

24

408B

Vacuum Motor, 3-stage

25

14

Washer, flat

26

8

Lock nut, 1/4-20

27

2013A

Gasket, vacuum

28

136

Nut, finish

29

14

Washer, flat

30

270

Bolt, 1/4 X 5"

31

MA-6

Manifold, vac motor, black

32

440

Exhaust Flange

34

8

Lock nut, 1/4-20

39

45

Quick Disconnect, male, 1/4 p.t.

40

115

Washer, fiber

40A

116A

Bushing, fiber

40B

31

Washer, flat, brass

41

928

Louver, 3", includes screws

42

909A

Strike, for latch

43

2001

Label, Cobra

44

937

Reducer Bushing, PVC

45

184

Cord Retainer, flexible

46

495A

Power cord, 25 ft

47

801C

Hinge pin

48

910-16.93 Axle Rod, 17"

ITEM PART

DESCRIPTION

49

2003

Wheel, 8"

50

27A

Axle Cap

51

8

Lock nut, 1/4-20

52

180

Axle bracket

53

5

Bolt, 1/4-20 X 3/4"

54

BS-6

Base, black

55

2002

Castor, 3"

56

HT-2

Holding Tank, white

57

207A

Filter, 40 Mesh, S/S

58

901

Lid, tinted

65

2007

Pump, 100 psi

66

166

Hose Clamp

67

108A

Hose Barb/Elbow

68

925

Hose, pump Inlet , 3/8" I.D.

69

925

Hose, pump outlet, 3/8" I.D.

74

CWBLK

Cord Wrap, black

75

203

Washer, flat, Nylon

76

260

Nut, Acorn

77

2005E

Switch plate

78

FP311

Switch, rocker, with cover

79

28

Screw, #4 X 3/8"