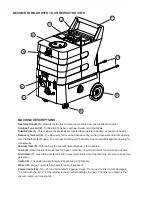

MACHINE DESCRIPTIONS

Operator Handle (1)

- Operator holds this to move the machine from one location to another.

Solution Tank Lid (2)

- Fill Solution Tank here with warm water and chemicals.

Switch Plate (3)

- This is where the switches are located that operate the pump, vacuum and heater.

Recovery Tank Lid (4)

- The Recovery Tank can be flushed out by running clean water into this opening

with the Drain Gate

(7)

open. The vacuum float Shut-OFF can also be accessed through this opening for

maintenance.

Vacuum Inlet (5)

- This is where the vacuum hose attaches to the machine.

Latch (6)

-

Open the latches to access the base compartment, which contains the motors and heater.

Drain Gate (7)

-

Open this gate to drain the recovered solution out of the machine. Be sure to keep this

gate clean.

Castor (8)

-

The castor swivels for easy maneuvering in tight spots.

Wheel (9)

-

Large, non-marking wheels for ease of transport.

Power Cords (10)

-

Two, 25 foot cords, rated 12 gauge, 3 wire. Do not use if either cord is damaged.

The cord with the red “H” at the retainer is the cord that operates the heat. The other cord powers the

vacuum, pump, and cooling fan.

BECOME FAMILAR WITH YOUR NEW EXTRACTOR

1

2

3

4

5

6

7

10

9

8