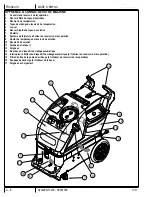

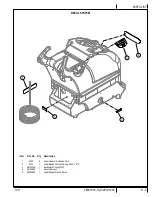

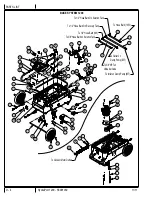

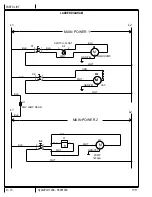

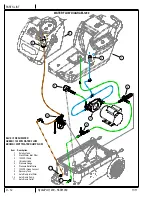

BASE SYSTEM 1200

Kit Item Ref.

No. Qty Description

K1 1 19

Nut-Nylock-ZP-1-4-20

K1

2

30

Washer Flat 3/16 Zinc Plat

K1 3 1

Nut-Nylon

Lock-SS-10-32

K1

4

1

Screw 10-32 X 5/8 Socket

5

35

3

Tie 4 Black Weather Resis

6

165

1

Hose Barb 1/4 Pipe X 1/2 Hose Brass

7

217

1

Reducer 3/8 Pipe Female To 1

K1 8 4

Washer-Flat-1/4x3/4x1/8-60

Dur0

9

220

1

Qd-Brass-1/4 Fpt-Socket Straight

10

237

1

Cap For Hose Fitting With Ch

11 239 1

Fitting-Adapter-Brass-3-4x3-8

K1 12

6 Screw-Fhp-SS-2x1/4-Sms

13

801

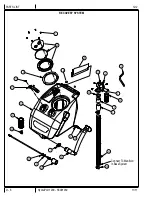

2

Hinge Pin Rod S/S 1/4 X

K2

14

1

Pump/Dump Pump 115v Self Priming

957A

1

Repair Kit for Auto Dump Pump

K1

15

1

Screw 2-56 X1 Panhead Philip

16

1

Nut. Finish 2-56 Thread Zp

17

1280

1

Elbow 90 Deg 1/4 Fpt X 1/4 F

18 1312

3

Mounting

Pad

19

1553

1

Tee Hose Barb 1/2 Hb X 1/2 Hb

K1

20

3

Bolt 1/4 X 20 6l Full Threa

K2

21

1659

1

Hose Barb 1/2 Hose To 3/8 M

22

2013

1

Gasket 1 Side Adhesive 5-1/2 O

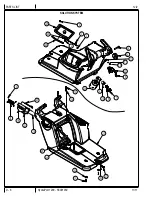

23

2092

2

Wheel 12”X1” Black On Gray 1/2” Axle

24

2142

4

Washer Fender Washer 1/4x1

25

FP618

1

Pump & Motor 1200 Psi For Adv

FP636

1

Motor, no pump

FP657

1

Pump, complete, no motor

1160K

1

Pump rebuild kit, valves & o-rings

1160A

1

Pump rebuild kit, plunger and seals

26

2166

1

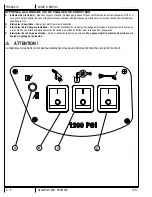

Gage Pressure 2000 Psi 2-1

27 2169

1

Plate

Mount

Aluminum

K1

28

5

Scr- Hex Ss 1/4-20 X .75

K1

29

8

Scr, Hex Hd Loc

30

56009005

2

Scr, Pan Phil Ss Type Ab 10-16 X .75

K1

31

1

Wsh, Flt .688 X 1.250 X .125

32

56105213

1

Harness-Main

1200psi

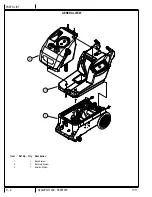

33

56105340

1

Base-1200

Psi

34

56105355

1

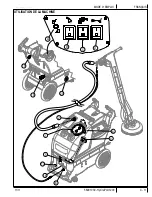

Hose-1/2 Id X 15 In. Red

35

56105356

1

Hose-1/2 Id X 22 In. Red

36

56105399

1

Hose 3/8 Id Red

37

56105407

1

Gasket-Poron

1/4x1/2x16.5

38

56105408

1

Gasket-Poron

1/4x1/2x63.5

Kit Item Ref.

No. Qty Description

39

56105414

2

Power Cord Pigtail-Yellow

K2

40

3

Term .250 Ins Tab

41

56263561

2

Hose, Spiral .500

K2

42

56381368

1

Elbow-90 Barb Male

43

56387302

1

Hose, Spiral .500

44

56397301

1

Hose, PVC .38id X 7.50

45

56463650

1

Handle

Grab

46

56471194

1

Latch

Assembly

K1

47

2

Washer 1 OD X 9/16 ID X

48

116A

1

Bushing 3/4 X 9/16

49

156USP

1

Hose Clamp-Size 28-1-9/16- 2 1/2

50

166USP

12

Hose

Clamp-SS-3/8-7/8

51

219USP

1

Quiick Connect Brass 1/4 Fpt

52

27AUSP

2

Axel Cap Black Pal Nut

K1

53

2

Washer Brass Half Hard 1 X

K1 54

2 Bolt-Php-SS-8-32x1/2

55

408G

1

Vacuum Motor, 3-Stage, 5.7

56

430A

1

Vac Hose 2” ID X 13.5 Black Rubber

57

4404C

1

Tank Mate Bar

58

459USP

2

Louver 2-1/2 Gray Plastic

59

45USP

1

Quick Disconnect Plug Male

60

905USP

2

Caster Swivel 4 Gray Non Ma

61

910-1863

1

Axel Rod Zinc Plated 1/2 Ro

62

92AUSP

1

Nipple Stainless Steel 1/4 Pip

63

92USP

1

Nipple-1-4

Pipe-Brass

64

MA-6

1

Manifold for Cobra Black

[

]

SUBSYP1

1

Syphon-Hose-HHP-12

[ ]

2154

2

Power Cord 12/3 SJTW 25 Y

K1

56105216

1

Kit-Hardware

Base

K2

56105242

1

Kit-Dump Pump Complete

[ ] = Not Shown

11/11

D - 5

56091030 - HydraPort 1200

PARTS LIST