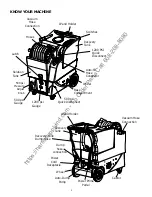

1200 PSI HIGH PRESSURE WASHER

1 Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness.

Make sure the hoses are in good condition and the spray nozzle(s) is tight.

2. When not using the auto-dump feature, just make sure the brass cap is screwed tightly on the hose

connector

fi tting on the rear of the machine. If you choose to use the auto-dump, connect the dump

hose to brass hose fi tting on the back of the machine, and place the open end of the hose in a drain.

Make sure the drain hose (recovery tank) is closed, and the lid is tight on the recovery tank.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGES.

3. If you choose to use the auto-fi ll feature, connect the fi ll hose to the auto-fi ll connector (located over

the solution tank fi ll hole). Turn on the water source, and allow the tank to fi ll with water. When using

the

auto-fi ll system, the auto-fi ll fl oat will automatically turn on and turn off as the tank empties and

then

fi lls. NOTE: If you are not going to use the auto-fi ll system, just fi ll the tank with water and

cleaning chemical. Follow chemical directions regarding dilution and mixing. Do not use harsh chemicals;

they may damage seals in pumps and valves, and cause the pump to wear prematurely.

NOTE: Never use water with a temperature exceeding 130 °F / 54 °C.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGES.

4. Pre-spray the area to be cleaned, with a pump-up sprayer, while the tank is fi lling. Follow chemical

directions.

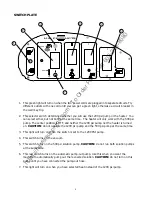

5. Plug in the two power cords. Do not connect both cords to the same outlet. The green, ‘separate

circuit’ locator light (1) on the switch plate should light up. If the locator light does not come on, check

the circuit breaker box in the wall, and/or try different outlets until it does turn on. Although all systems

in the machine may work correctly if you are not on two circuits, a circuit breaker in a wall panel may

trip. If you make sure the green light is turned on, you will prevent tripped circuit breakers. Turn on the

1200 PSI pump by placing the HIGH PRESSURE/HEAT selection switch (2) in the UP position, to select

the 1200 PSI Pump. NOTE: both the 1200 PSI pump and the heat can not operate at the same

time. NOTE: this switch (2) is off when it is set to the middle position and neither the 1200 PSI pump

nor the heater is selected.

6. Prime the 1200 psi pump using the ‘power prime’ system: turn on both the pump and the vacuum

(3), cover the hole in the vacuum hose barb on the top of the machine with your hand, then depress

the Power Prime Pedal (located on the back of the machine). This will pull trapped air through the

pump and into the recovery tank, priming the pump. You should notice a change in the ‘tone’ of the

pump (smoother, with less rattle), and the water being pulled into the recovery tank will change from a

white,

sputtering

fl ow to a clear, solid stream. NOTE: priming requires a full Holding tank, and it may

take between 20 to 90 seconds. Once the pump has primed, release the Power Prime Pedal, and

turn both the pump and the vacuum off. Momentarily depress the Power Prime pedal again to release

any built-up back pressure. Proceed to Step 9.

OPERATION

REFER TO THE DIAGRAMS ON THE PREVIOUS PAGE

CAUTION: Use care when handling hazardous chemicals.

CAUTION: Never leave the machine running when you are not actively using it.

CAUTION: Always use a defoamer when foaming occurs to prevent vacuum motor damage.

DANGER: Do NOT use solvents, or any chemicals that may be fl ammable, explosive or

combustible.

5

https://harrissupplyind.com - To Order Parts Call 608-268-8080