USING THE AUTO-FILL AND/OR AUTO-DUMP FEATURES

1 Chemical Supply:

• Place the container of concentrated chemical cleaner -- use a product with a pH between 6 and 9 to avoid premature

pump wear (which would void the warranty) -- in the holder on top of the recovery tank.

• Remove the cap on the container. Insert the end of the clear tubing with the foot valve into the container. NOTE: the

stainless steel weight at the foot valve will keep the valve at the bottom of the chemical container.

• The chemical flow may be turned on or off by applying the pinch clamp to the tubing, between the chemical container

and the auto-fill valve.

2 Chemical Injection Flow Rate:

• Metering tips are used to control the rate at which the cleaning chemical feeds into the supply water.

The following table illustrates the ratio of chemical, in ounces, to each gallon of water coming into the tank. The tips

are color coded for ease of use.

• NOTE: the flow rate values in the table are based on a chemical with the same viscosity as water.

3

Operation:

• Attach a 3/4” garden hose to the autofill valve, and connect the other end of the hose to your water source.

• Make sure the float that hangs from the autofill valve into the tank is free of obstruction and can move freely.

• Turn the water supply on.

• As the tank fills, the chemical concentrate will be drawn from the chemical container, will pass through the clear tubing

to the valve, and will be mixed into the water stream.

• The autofill float will automatically shut-off the flow of incoming water when the tank is nearly full, and it will allow the

valve to open again once the water level has dropped to a predetermined level.

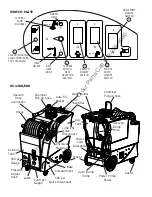

AUTO-FILL

To change the metering tip: find the, plastic hose-clamp on the chemical feed tubing, near the Auto-fill valve. Refer to

illustration above. Open the clamp by sliding the two ends of clamp (where they come together) apart, sideways, in opposite

directions until the clamp opens. Then pull the clear chemical supply hose off the hose barb at the Auto-Fill valve. Unscrew

the metering tip from the end of the hose barb. Select the tip that will provide you with the desired chemical ratio (see chart,

above). Screw the selected tip into the end of the hose barb. Snug-up the tip, but do not overtighten. Slide the hose back

over the tip and the hose barb. Install the clamp onto the hose so it is over the hose barb, and squeeze the clamp closed.

* NOTE: the turquoise colored tip is factory installed

(provides a 1 to 1 ratio -- see table).

METERING TIP FLOW RATES

COLOR

OZ/GAL

WHITE

3.00

GREEN

3.50

BLUE

4.00

YELLOW

5.25

BLACK

6.75

PURPLE

10.50

GRAY

14.00

COLOR

OZ/GAL

TAN

0.60

ORANGE

0.70

TURQUOISE*

1.00

PINK

1.25

LIGHT BLUE

1.75

BROWN

2.00

RED

2.75

Chemical

Holder

Basket

Pinch

Clamp

Chemical

Proportioner

&

Auto-fill

Valve

Hose

Connection

AUTO-FILL

Clamp

Chemical

Supply

hose

Chemical

Pick-up

Tube

CAUTION: Use care when handling

hazardous chemicals.

DANGER: Do NOT use solvents, or

any chemicals that may be flammable,

explosive, or combustible.

https://harrissupplyind.com - To Order Parts Call 608-268-8080