NOTE: This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories,

shops and offices other than normal residential housekeeping purposes.

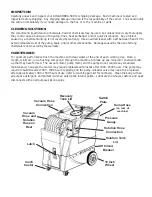

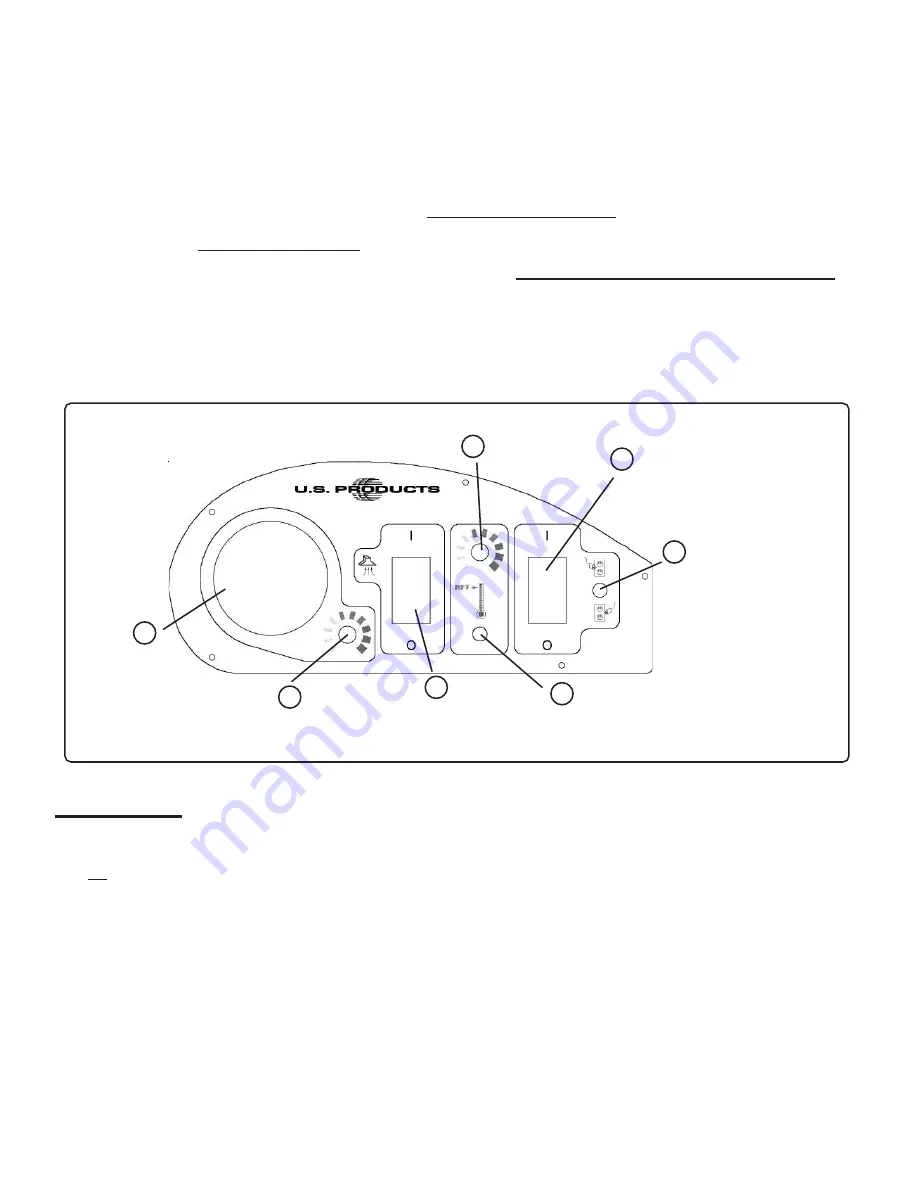

SWITCH PLATE

PUMP

PRESSURE

ADJUST

TEMPERATURE

ADJUST

CIRCUIT LOCATOR

LIGHT INDICATES

TWO CIRCUITS.

HEATER WILL

AUTOMATICALLY

TURN ON

BYPASS SWICH.

TURNS THE HEATER ON

WHEN GREEN LIGHT IS

NOT ON

1

2

3

VACUUM

ON/OFF

SWITCH

4

5

6

INDICATES

SPRAYING

PRESSURE

PRESSURE

GAUGE

Record the serial number and model of your new extractor here:

(and be sure to mail your warranty card)

Serial Number: __________________ Model: KING COBRA-500-CSA

Purchase Date:__________________

Write the name and phone number of your distributor:

_____________________________________

7

RED LIGHT INDICATES

HEATER IS HEATING

1

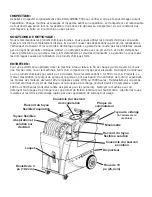

Inspect the machine, hoses, and cleaning tools for cleanliness and completeness.

2

Fill the solution tank with water. Using warm water may be a benefit in cleaning effectiveness, but

do not use hot water (above 130

°

F / 54

°

C) in the tank.

3

Screw the lid on the recovery tank. Close the dump hose.

4

Plug in the power cords. Do not connect both cords to the same outlet; the green, circuit locator light

(1) on the switch plate should light up. If the locator light does not come on, try different outlets until it

does. If you are certain the cords are on separate circuits, turn the Bypass switch (2) on.

CAUTION: using the Bypass switch (2) when the cords are on the same circuit may cause the

breaker in the wall to trip. NOTE: the receptacle on the left (viewed from behind the machine) powers

the heater.

The red light (6) will turn on only when the heat exchanger is actively heating.

OPERATION

be sure to register your warranty -- www.usproducts.com